Are you gearing up for a career in Beaming Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Beaming Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

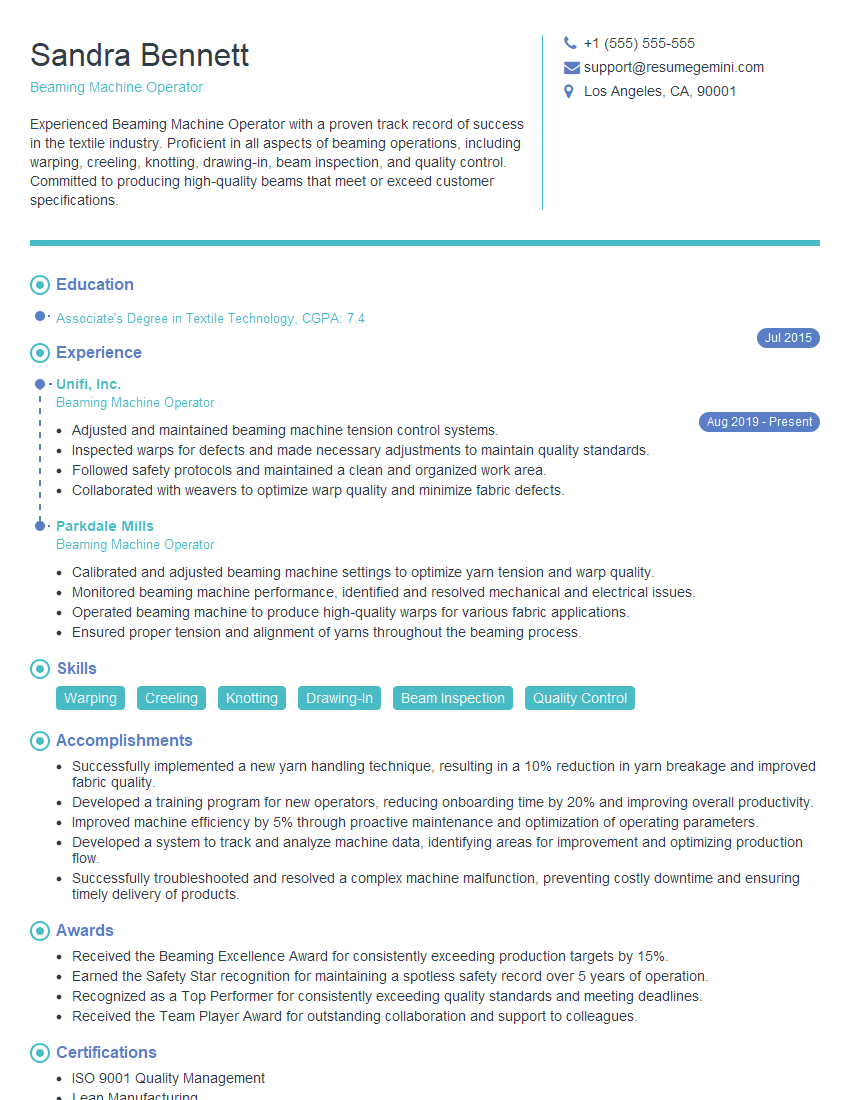

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beaming Machine Operator

1. Can you describe the process of beaming yarn onto a loom?

The beaming process involves transferring yarn from multiple creels onto a loom beam in a parallel fashion. Here’s a step-by-step overview:

- Creel Setup: Yarns from multiple creels are guided through tensioners and other devices to ensure uniform tension.

- Beam Preparation: The loom beam is prepared by winding a foundation layer of yarn onto it, followed by the application of adhesive or sizing.

- Yarn Transfer: The yarns from the creels are drawn through a reed or comb to maintain spacing and then wound onto the loom beam.

- Tension Control: Throughout the process, tension is carefully controlled to prevent yarn breaks and ensure consistent winding.

- Beam Doffing: Once the beam is full, it is removed from the beaming machine and transferred to the loom for weaving.

2. What are some of the common problems that can occur during beaming and how do you resolve them?

Yarn Breakage

- Check yarn tension and adjust if necessary.

- Inspect yarn for weak spots or damage and replace as needed.

- Clean the yarn path to remove any obstructions.

Tension Variation

- Calibrate tensioners to ensure uniform yarn tension.

- Check the alignment of yarn guides and adjust.

- Lubricate moving parts to reduce friction.

Beam Defects

- Check the beam for any damage or imperfections.

- Adjust the winding speed to achieve optimal yarn distribution.

- Inspect the beam for proper adhesive application.

3. How do you ensure that the yarn is wound evenly and consistently onto the beam?

- Proper Yarn Tension: Maintaining consistent yarn tension throughout the beaming process is crucial.

- Yarn Guiding: Ensuring that the yarn is guided properly through the reed or comb prevents yarn overlap and uneven winding.

- Beam Traverse Control: The traverse motion of the beam must be controlled precisely to distribute the yarn evenly across its width.

- Regular Monitoring: Regularly monitoring the beaming process and making adjustments as needed helps maintain consistency.

4. What is the importance of beam flange alignment and how do you achieve it?

Beam flange alignment is crucial to ensure proper yarn winding and prevent yarn damage. Here’s why and how to achieve it:

- Yarn Clearance: Proper flange alignment provides sufficient clearance for the yarn to be wound onto the beam without rubbing against the flanges.

- Yarn Tension: Misaligned flanges can cause uneven yarn tension, leading to yarn breakage or defects.

- Alignment Methods: Alignment can be achieved using dial indicators, laser alignment tools, or by manually adjusting the flanges until they are parallel.

5. How do you determine the correct beam size and flange width for a specific weaving project?

- Warp Yarn Density: The number of warp yarns per unit length determines the beam size required.

- Yarn Linear Density: The thickness of the yarn influences the flange width selection.

- Weaving Width: The width of the fabric being woven dictates the minimum beam flange width.

- Beam Capacity: The beam size must accommodate the total length of yarn required for the project.

6. Describe the different types of beaming machines and their suitability for various applications

- Sectional Warping Machines: Suitable for high-volume production of large beams, where each section is wound separately and later combined.

- Direct Warping Machines: Used for continuous yarn winding directly onto the beam, offering higher efficiency but limited flexibility.

- Creel-Fed Warping Machines: Designed for warping yarns from multiple creels onto the beam, providing versatility in yarn selection.

7. What are the key maintenance tasks required for a beaming machine?

- Regular Cleaning: Removing dust, yarn scraps, and adhesive residue from the machine is essential.

- Tensioner Calibration: Calibrating tensioners ensures accurate yarn tension control.

- Lubrication: Lubricating moving parts reduces friction and wear, extending machine life.

- Beam Inspection: Checking beams for damage, dirt, or imperfections before use.

- Safety Checks: Ensuring all safety guards are in place and functional.

8. How do you optimize beaming efficiency and minimize yarn waste?

- Proper Yarn Preparation: Pre-treating yarn to remove hairiness and weak spots reduces breakage.

- Tension Control: Maintaining consistent yarn tension minimizes yarn breaks and uneven winding.

- Yarn Guiding: Optimizing yarn guiding prevents tangles and ensures even distribution.

- Beam Design: Selecting the appropriate beam size and flange width reduces yarn damage and waste.

- Operator Training: Training operators on proper beaming techniques improves efficiency and reduces errors.

9. Explain the quality control measures involved in the beaming process

- Yarn Inspection: Inspecting yarns for defects or damage before beaming.

- Beam Inspection: Checking the finished beam for proper winding, tension, and absence of defects.

- Measuring Devices: Using measuring devices to ensure the beam meets specifications.

- Process Monitoring: Regularly monitoring the beaming process to identify and address any issues.

- Documentation: Maintaining records of beaming parameters and quality checks.

10. Discuss the importance of safety in the beaming operation

- Machine Guarding: Ensuring all moving parts are properly guarded to prevent accidents.

- Personal Protective Equipment: Using safety glasses, gloves, and appropriate clothing.

- Proper Handling: Handling beams and yarns safely to avoid injuries.

- Ergonomic Considerations: Designing the work area to minimize strain and fatigue.

- Emergency Procedures: Having clear emergency procedures in place and training operators how to respond.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beaming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beaming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Beaming Machine Operators play a critical role in the textile industry, ensuring that raw yarn is prepared for weaving or knitting. Their main responsibilities revolve around operating, maintaining, and troubleshooting beaming machines.

1. Machine Operation

Operate beaming machines to wind yarn onto beams.

- Load beams onto the machine.

- Thread yarn through the machine.

- Adjust machine settings to achieve optimal winding tension.

2. Quality Control

Inspect yarn for irregularities and ensure proper winding.

- Check yarn tension to prevent breakage.

- Monitor beam diameter to maintain uniform winding.

- Identify and resolve any defects in the winding process.

3. Machine Maintenance

Perform regular maintenance tasks to keep machines in optimal condition.

- Clean and lubricate machine parts.

- Replace worn or damaged components.

- Troubleshoot machine malfunctions and resolve issues promptly.

4. Production Monitoring

Monitor production output and ensure efficiency.

- Track beam production rates.

- Identify and address bottlenecks in the process.

- Report any production issues or delays.

Interview Tips

To ace your interview for a Beaming Machine Operator position, it’s crucial to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Role

Take the time to research the company you’re applying to and the specific role. Understand their products, services, and industry. Research the responsibilities of a Beaming Machine Operator and familiarize yourself with the equipment and techniques involved.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

- Talk to people in your network who work in textiles or manufacturing.

2. Highlight Your Skills and Experience

Emphasize your technical skills and experience related to beaming machine operation. Quantify your accomplishments and provide specific examples of how you have contributed to production and efficiency.

- Highlight your ability to operate and maintain a variety of beaming machines.

- Describe your experience in quality control and defect detection.

- Share examples of your troubleshooting skills and how you resolved machine malfunctions.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. This will help you feel confident and articulate during the interview. Here are some examples of common interview questions:

- Tell me about your experience as a Beaming Machine Operator.

- What are the most important qualities of a successful Beaming Machine Operator?

- Describe a time when you had to troubleshoot a complex problem with a beaming machine.

4. Be Enthusiastic and Professional

Show your enthusiasm for the role and the company. Be respectful, professional, and dress appropriately. Arrive on time for your interview and demonstrate a positive attitude.

- Ask thoughtful questions about the company and the role.

- Thank the interviewer for their time and consideration.

- Follow up with a thank-you note after the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Beaming Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!