Feeling lost in a sea of interview questions? Landed that dream interview for Bearing Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bearing Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

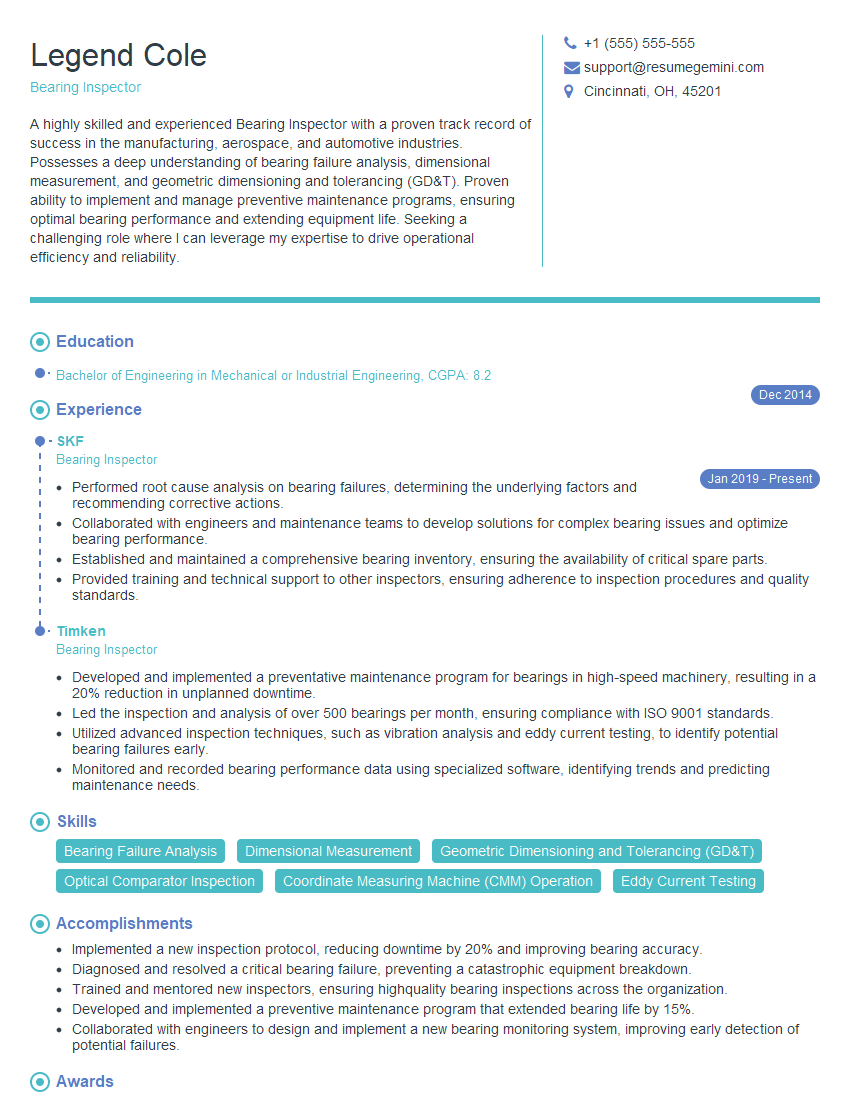

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bearing Inspector

1. Describe the different types of bearings and their applications?

Bearings are mechanical components that allow relative motion between two surfaces. There are several types of bearings, each with its own unique design and application.

- Rolling bearings use rolling elements, such as balls or rollers, to reduce friction between two surfaces. These bearings are commonly used in applications where high speeds and loads are involved.

- Plain bearings, also known as slide bearings, use a sliding contact between two surfaces. These bearings are typically used in applications where low speeds and loads are involved.

- Hydrostatic bearings use a thin film of pressurized fluid to separate two surfaces. These bearings provide very low friction and are used in applications where precision and high speeds are required.

- Gas bearings use a thin film of gas to separate two surfaces. These bearings provide very low friction and are used in applications where high speeds and cleanliness are required.

2. What are the key factors to consider when selecting a bearing for a specific application?

- Load capacity: The bearing must be able to withstand the loads that will be applied to it.

- Speed: The bearing must be able to operate at the desired speed without overheating or failing.

- Environment: The bearing must be able to withstand the environmental conditions in which it will be operating, such as temperature, humidity, and contamination.

- Cost: The bearing must be affordable for the application.

3. What are the different types of bearing failures and their causes?

- Wear: Wear is the gradual loss of material from the bearing surfaces. This can be caused by abrasion, adhesion, or erosion.

- Fatigue: Fatigue is the failure of a bearing due to repeated loading. This can occur when the bearing is subjected to high loads or vibrations.

- Corrosion: Corrosion is the deterioration of the bearing surfaces due to chemical attack. This can be caused by exposure to moisture, acids, or other corrosive substances.

- Contamination: Contamination is the introduction of foreign particles into the bearing. This can cause wear, fatigue, or corrosion.

4. What are the preventive maintenance tasks that can be performed to extend the life of a bearing?

- Lubrication: Bearings must be properly lubricated to reduce friction and wear.

- Inspection: Bearings should be inspected regularly for signs of wear, fatigue, corrosion, or contamination.

- Cleaning: Bearings should be cleaned regularly to remove contaminants.

- Alignment: Bearings must be properly aligned to avoid premature failure.

5. What are the latest developments in bearing technology?

- Ceramic bearings: Ceramic bearings are made of ceramic materials, such as silicon nitride or zirconia. These bearings are very hard and wear-resistant, and they can operate at high speeds and temperatures.

- Self-lubricating bearings: Self-lubricating bearings are bearings that are pre-lubricated with a solid lubricant, such as graphite or PTFE. These bearings do not require additional lubrication, and they can operate in harsh environments.

- Active magnetic bearings: Active magnetic bearings use magnetic forces to levitate a rotor, eliminating the need for physical contact between the rotor and the bearing. These bearings provide very low friction and can operate at very high speeds.

6. What are the most common mistakes made when installing bearings?

- Improper lubrication: Bearings must be properly lubricated to reduce friction and wear. Using too little or too much lubricant can damage the bearing.

- Incorrect alignment: Bearings must be properly aligned to avoid premature failure. Misalignment can cause the bearing to bind or overheat.

- Contamination: Bearings should be protected from contamination during installation. Contaminants can cause wear, fatigue, or corrosion.

- Overloading: Bearings must not be overloaded. Overloading can cause the bearing to fail prematurely.

7. What are the best practices for troubleshooting bearing problems?

- Identify the symptoms of the problem: What are the signs and symptoms of the problem?

- Determine the root cause of the problem: What is causing the problem?

- Develop a solution to the problem: How can the problem be solved?

- Implement the solution and verify that it is effective: Did the solution solve the problem?

8. What are the key quality control measures that should be implemented in a bearing manufacturing process?

- Material inspection: The raw materials used in the bearing manufacturing process should be inspected to ensure that they meet the required specifications.

- Process control: The manufacturing process should be controlled to ensure that the bearings are produced to the desired quality standards.

- Product inspection: The finished bearings should be inspected to ensure that they meet the required specifications.

9. What are the emerging trends in the bearing industry?

- Increased use of ceramic bearings: Ceramic bearings are becoming increasingly popular due to their high hardness and wear resistance.

- Development of self-lubricating bearings: Self-lubricating bearings are becoming increasingly popular due to their ability to operate in harsh environments.

- Increased use of active magnetic bearings: Active magnetic bearings are becoming increasingly popular due to their ability to provide very low friction and operate at very high speeds.

10. What are the challenges facing the bearing industry?

- Increased demand for bearings: The demand for bearings is increasing due to the growth of the automotive, aerospace, and industrial sectors.

- Rising costs of raw materials: The rising costs of raw materials are putting pressure on bearing manufacturers to reduce costs.

- Increased competition: The bearing industry is becoming increasingly competitive, with new manufacturers entering the market.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bearing Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bearing Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bearing Inspectors are responsible for ensuring that bearings meet the required specifications and quality standards. Their key job responsibilities include:Inspecting bearings for defects using a variety of inspection techniques, including visual, dimensional, and microscopic inspections.

1. Identifying defects

Bearings are inspected for a variety of defects, including:

- Cracks

- Dents

- Scratches

- Corrosion

- Misalignment

2. Measuring dimensions

Bearings are also inspected to ensure that they meet the required dimensional specifications. This includes measuring the bearing’s inner and outer diameters, width, and thickness.

3. Evaluating surface finish

The surface finish of a bearing is also important, as it can affect the bearing’s performance and lifespan. Inspectors use a variety of techniques to evaluate the surface finish of bearings, including visual inspection, profilometry, and interferometry.

4. Testing bearings

In addition to inspecting bearings, inspectors may also test bearings to ensure that they meet the required performance specifications. This may include testing the bearing’s load capacity, speed, and noise.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Bearing Inspector position:

1. Research the company and position

Before you go to your interview, take some time to research the company and the position you are applying for. This will give you a better understanding of the company’s culture and the specific requirements of the position. You can also use this information to tailor your answers to the interviewer’s questions.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is a good idea to practice answering these questions in advance so that you can give clear and concise answers.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting. You should also avoid wearing strong perfumes or colognes.

4. Be confident

Confidence is key when it comes to interviewing. Believe in yourself and your abilities, and don’t be afraid to sell yourself. However, it is important to be genuine and avoid coming across as arrogant.

5. Ask questions

Asking questions shows that you are engaged in the interview and that you are interested in the position. It also gives you an opportunity to learn more about the company and the position. However, it is important to ask thoughtful questions that are relevant to the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bearing Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.