Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bearing Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

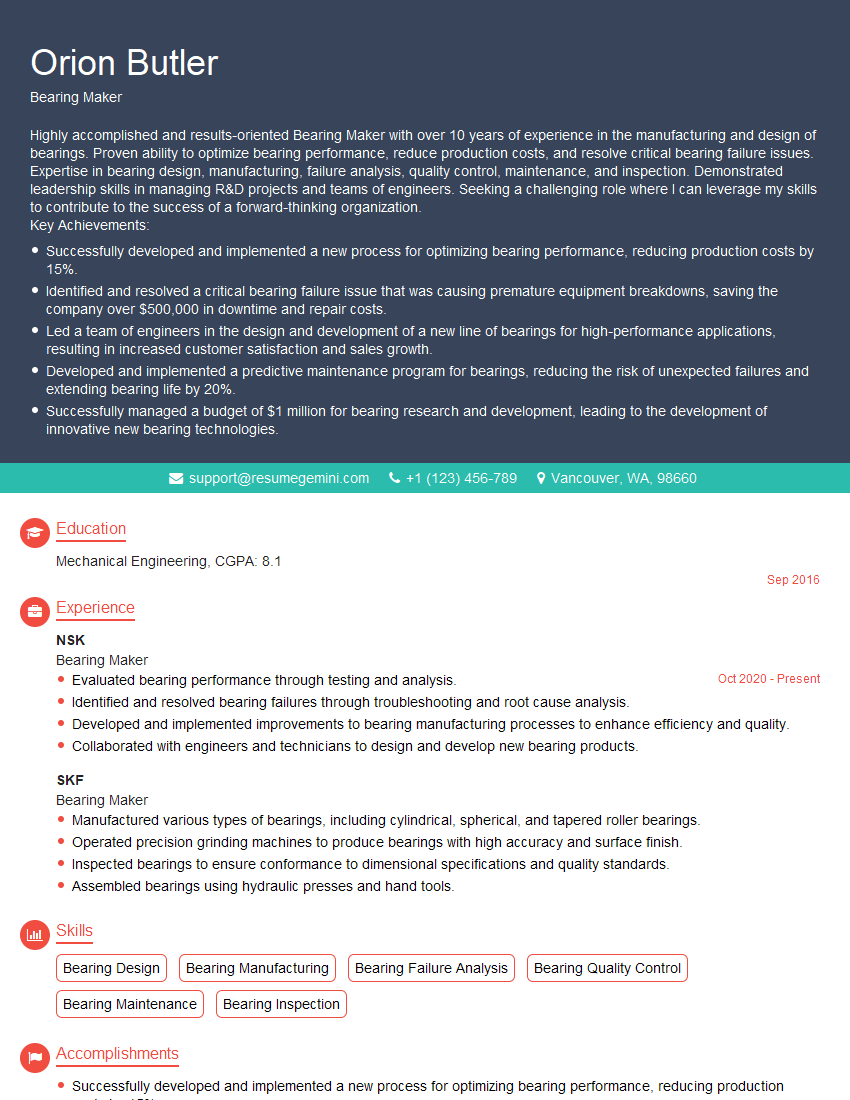

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bearing Maker

1. What are the key dimensions of a bearing that need to be considered when selecting one for an application?

- Inner diameter: The diameter of the shaft or housing that the bearing will fit onto.

- Outer diameter: The diameter of the outer race of the bearing.

- Width: The thickness of the bearing.

- Load capacity: The amount of weight or force that the bearing can support.

2. What are the different types of bearings?

Rolling element bearings

- Ball bearings: Use balls as the rolling elements.

- Roller bearings: Use rollers as the rolling elements.

Plain bearings

- Journal bearings: Use a rotating shaft that slides against a stationary bearing surface.

- Thrust bearings: Use a rotating surface that slides against a stationary surface.

3. What are the factors that affect the life of a bearing?

- Load: The amount of weight or force that the bearing is subjected to.

- Speed: The speed at which the bearing is rotating.

- Lubrication: The type and amount of lubrication that is used.

- Environment: The temperature, humidity, and other environmental factors that the bearing is exposed to.

4. What are some common problems that can occur with bearings?

- Wear: The gradual loss of material from the bearing surfaces.

- Corrosion: The chemical breakdown of the bearing surfaces.

- Contamination: The presence of foreign particles in the bearing.

- Misalignment: The incorrect alignment of the bearing with the shaft or housing.

5. What are some tips for selecting the right bearing for an application?

- Consider the load, speed, and environment that the bearing will be subjected to.

- Choose a bearing that has the appropriate dimensions and load capacity.

- Use the correct type of lubrication for the bearing.

- Ensure that the bearing is properly installed and aligned.

6. What are some of the latest trends in bearing technology?

- Ceramic bearings: Bearings made from ceramic materials that are harder and more wear-resistant than traditional steel bearings.

- Magnetic bearings: Bearings that use magnetic levitation to support the shaft, eliminating friction.

- Self-lubricating bearings: Bearings that are impregnated with a lubricant that gradually releases over time, reducing maintenance requirements.

7. What are some of the challenges facing the bearing industry?

- Increasing demand for bearings: The growing demand for bearings from industries such as automotive, aerospace, and medical.

- Increased competition: The increasing number of bearing manufacturers, both domestic and international.

- Technological advances: The rapid pace of technological advances in bearing design and manufacturing.

8. What are some of the opportunities for the bearing industry?

- Growing demand for bearings: The increasing demand for bearings from emerging markets.

- New applications for bearings: The development of new applications for bearings in fields such as robotics and renewable energy.

- Technological advances: The potential for technological advances to improve the performance and efficiency of bearings.

9. What are some of the key trends that you expect to see in the bearing industry in the next 5 years?

- Increased use of ceramic bearings: Ceramic bearings are expected to become more popular due to their superior performance and durability.

- Increased use of magnetic bearings: Magnetic bearings are expected to become more popular due to their ability to eliminate friction and reduce maintenance costs.

- Increased use of self-lubricating bearings: Self-lubricating bearings are expected to become more popular due to their reduced maintenance requirements.

10. What are some of the challenges that you expect to face in the bearing industry in the next 5 years?

- Increased competition: The bearing industry is expected to become more competitive in the next 5 years.

- Technological advances: The rapid pace of technological advances in bearing design and manufacturing is expected to continue.

- Globalization: The bearing industry is expected to become more globalized in the next 5 years.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bearing Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bearing Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bearing Makers are responsible for manufacturing and repairing bearings. They use a variety of tools and machines to shape and finish bearing surfaces, and they must have a strong understanding of metallurgy and engineering principles.

1. Manufacturing Bearings

Bearing Makers use a variety of machines to manufacture bearings, including lathes, milling machines, and grinders. They must be able to operate these machines safely and efficiently, and they must have a good understanding of the tolerances required for bearing production.

- Set up and operate machines to form, grind, and finish bearing components

- inspect bearing components to ensure they meet specifications

2. Repairing Bearings

Bearing Makers also repair bearings that have been damaged or worn. They must be able to diagnose the problem and determine the best course of action. They may need to replace individual components or rebuild the entire bearing.

- Diagnose problems with bearings and determine the best course of action

- Repair or replace bearing components as needed

3. Quality Control

Bearing Makers are responsible for ensuring that the bearings they produce meet the required quality standards. They must be able to identify and correct any defects in the manufacturing process.

- Inspect bearings to ensure they meet specifications

- Identify and correct any defects in the manufacturing process

4. Maintenance

Bearing Makers are also responsible for maintaining the equipment they use. They must be able to troubleshoot and repair problems, and they must keep the equipment clean and in good working order.

- Maintain the equipment used to manufacture and repair bearings

- Troubleshoot and repair problems with equipment

Interview Tips

Preparing for an interview for a Bearing Maker position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company

Before you go on an interview, it’s important to do some research on the company. This will help you understand their culture and values, and it will also give you a better idea of the position you’re applying for.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work for the company

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, so it’s a good idea to practice answering them ahead of time. This will help you feel more confident and prepared during your interview.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in the bearing industry. Be prepared to talk about your skills and knowledge, and be sure to highlight any relevant projects or accomplishments.

- Describe your experience in manufacturing bearings

- Talk about your experience in repairing bearings

- Highlight any relevant projects or accomplishments

4. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions that you have. This shows that you’re interested in the position and that you’re taking the interview seriously.

- What are the biggest challenges facing the bearing industry?

- What are the company’s plans for the future?

- What is the company culture like?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bearing Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bearing Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.