Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Beater Dumper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Beater Dumper so you can tailor your answers to impress potential employers.

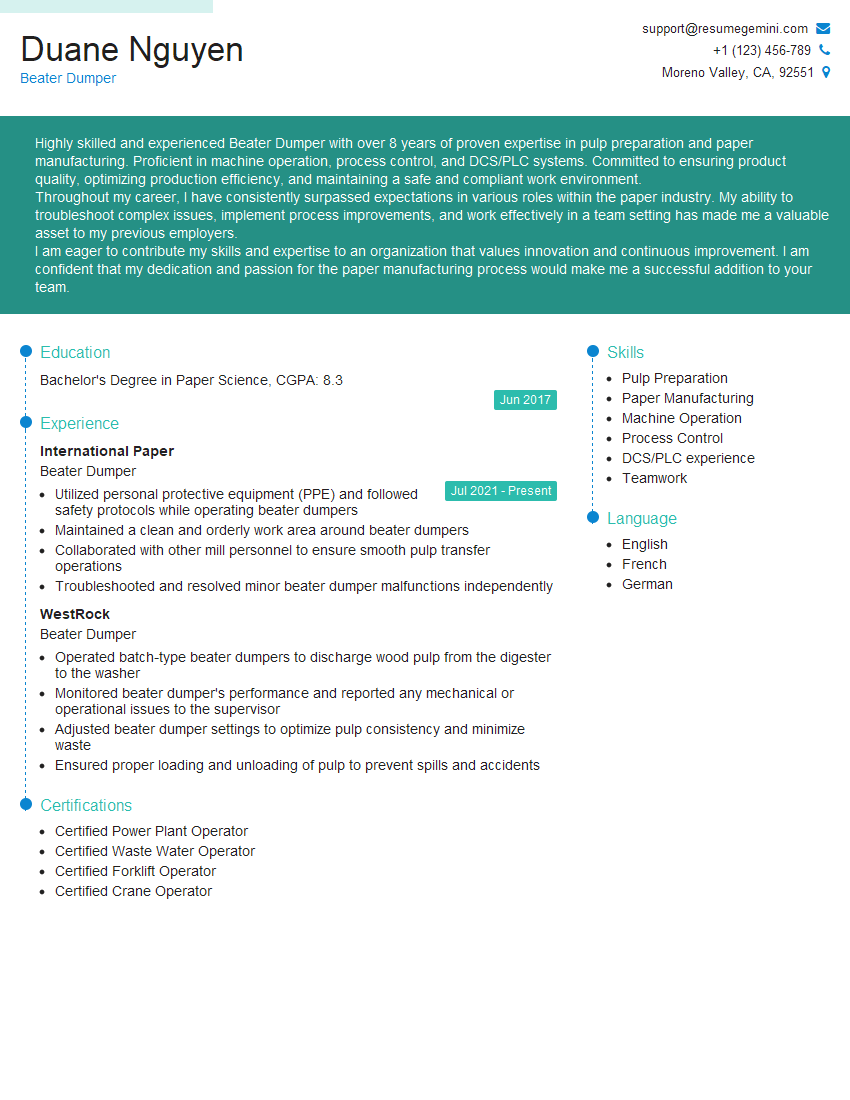

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beater Dumper

1. What are the responsibilities of a Beater Dumper operator?

- Operate the beater dumper to mix and evenly distribute concrete ingredients.

- Control the speed and direction of the drum to ensure proper mixing.

- Monitor the mixing process and make adjustments as needed.

- Unload the mixed concrete into transit mixers or other designated areas.

- Maintain and clean the beater dumper and its components.

2. What are the safety precautions that you need to follow when operating a Beater Dumper?

Personal Protective Equipment (PPE)

- Always wear appropriate PPE including safety glasses, gloves, earplugs, and a hard hat.

- Wear sturdy, slip-resistant footwear.

Machine Operation

- Inspect the beater dumper before each use and ensure it is in good working condition.

- Never operate the beater dumper while under the influence of alcohol or drugs.

- Be aware of your surroundings and maintain a safe distance from other workers and equipment.

- Follow all manufacturer’s instructions for safe operation.

Concrete Handling

- Be aware of the hazards associated with concrete, including its caustic nature and the potential for dust inhalation.

- Use proper techniques for handling and unloading concrete.

3. How would you troubleshoot a Beater Dumper that is not mixing properly?

- Check the drum paddles and liner plates for wear or damage.

- Inspect the drive system for any loose or damaged components.

- Verify that the water and concrete are being added in the correct proportions.

- Adjust the mixing speed and/or duration as needed.

- Contact a qualified mechanic if the problem persists.

4. What are the different types of concrete mixes that can be produced using a Beater Dumper?

- Standard concrete mix

- High-strength concrete mix

- Lightweight concrete mix

- Self-compacting concrete mix

- Fiber-reinforced concrete mix

5. How do you maintain a Beater Dumper to ensure its longevity and optimal performance?

- Regularly inspect the drum, paddles, and liner plates for wear or damage.

- Lubricate all moving parts according to the manufacturer’s instructions.

- Clean the beater dumper thoroughly after each use to remove any concrete residue.

- Perform preventative maintenance as recommended by the manufacturer.

6. How do you calculate the amount of concrete required for a specific job?

- Determine the volume of the area to be filled using the appropriate formula (e.g., length x width x height for a rectangular area).

- Multiply the volume by the desired thickness of the concrete layer.

- Adjust the calculated amount based on the specific concrete mix being used.

7. What are the common quality control procedures for concrete?

- Slump test to measure the consistency of the concrete mix.

- Air content test to determine the amount of air entrained in the concrete.

- Compressive strength test to assess the strength of the hardened concrete.

8. What is the difference between a Beater Dumper and a Transit Mixer?

- Beater Dumper: used to mix concrete ingredients and unload the mixed concrete at the job site.

- Transit Mixer: used to transport and mix concrete during transit, allowing for continuous mixing and delivery to multiple locations.

9. How do you handle concrete spills and clean up after a Beater Dumper operation?

- Contain the spill using absorbent materials like sand or sawdust.

- Scoop up the spilled concrete and dispose of it properly.

- Clean the beater dumper and surrounding area thoroughly using water and a stiff brush.

10. What are some of the challenges you have faced as a Beater Dumper operator and how did you overcome them?

- Challenge: Ensuring a consistent concrete mix.

- Solution: Regularly calibrated the beater dumper and closely monitored the mixing process.

- Challenge: Operating in tight or confined spaces.

- Solution: Used a smaller beater dumper or employed a spotter for assistance.

- Challenge: Dealing with inclement weather conditions.

- Solution: Adjusted the mixing process and used protective gear to minimize the impact of weather.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beater Dumper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beater Dumper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Beater Dumper is accountable for operating a specialized piece of construction equipment called a beater dumper. They are responsible for transporting and dumping various materials within construction sites and other industrial environments.

1. Equipment Operation and Maintenance

The beater dumper is a self-loading, self-unloading machine used to transport and distribute materials such as soil, sand, and gravel. The job responsibilities of a Beater Dumper include:

- Operating the beater dumper safely and efficiently to transport materials on construction sites.

- Loading and unloading materials from the beater dumper as directed by supervisors or site engineers.

- Monitoring the condition of the beater dumper and performing routine maintenance tasks to ensure it is in good working order.

2. Material Handling

Beater Dumpers are responsible for handling a variety of materials, including:

- Soil

- Sand

- Gravel

- Construction debris

3. Safety and Compliance

Beater Dumpers must adhere to all safety regulations and guidelines while operating the equipment. This includes:

- Wearing appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, and gloves.

- Following established safety procedures for operating the beater dumper.

- Being aware of the surroundings and potential hazards while operating the equipment.

Interview Tips

To ace the interview, it is important for candidates to be well-prepared. The following interview tips and hacks can help candidates make a positive impression and increase their chances of landing the job.

1. Research the Company and the Position

Before the interview, candidates should thoroughly research the company and the specific beater dumper position they are applying for. This will help them understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website and social media pages.

- Read industry news and articles about the company.

- Look for information about the specific beater dumper position on job boards and company websites.

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked in beater dumper interviews. By practicing your answers to these questions, candidates can feel more confident and prepared during the interview.

- Tell me about your experience operating beater dumpers.

- What are your strengths and weaknesses as a beater dumper operator?

- Why are you interested in this position?

- What are your salary expectations?

3. Highlight Your Skills and Experience

Candidates should highlight their skills and experience that are relevant to the beater dumper position. This includes:

- Experience operating beater dumpers or similar equipment.

- Knowledge of construction materials and their properties.

- Strong safety record.

- Ability to work independently and as part of a team.

4. Be Enthusiastic and Positive

Employers are looking for candidates who are enthusiastic about the beater dumper position and the construction industry. Candidates should be positive and upbeat during the interview and demonstrate their passion for the work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Beater Dumper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.