Are you gearing up for an interview for a Beater Engineer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Beater Engineer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

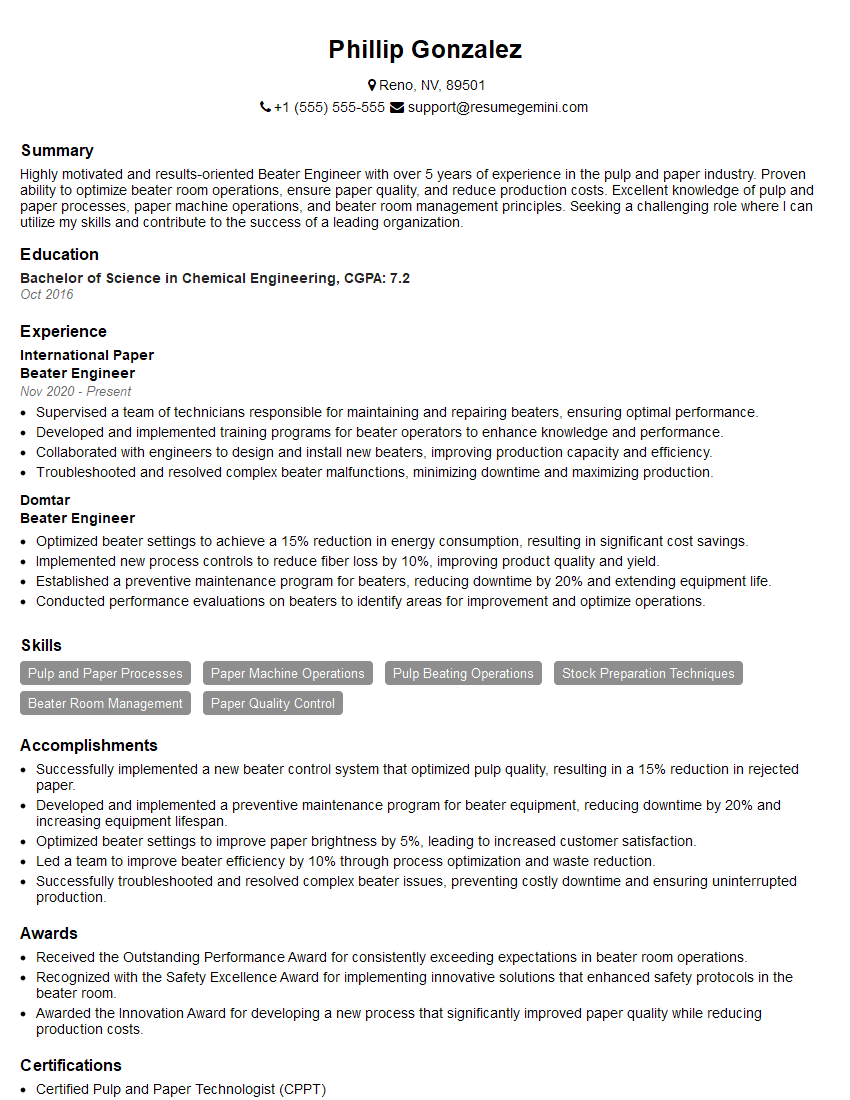

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beater Engineer

1. What are the key responsibilities of a Beater Engineer?

The key responsibilities of a Beater Engineer include:

- Operating and maintaining beater equipment to produce high-quality pulp

- Monitoring and controlling process parameters to ensure optimal performance

- Troubleshooting and resolving operational issues

- Maintaining a safe and clean work environment

- Following established quality control procedures

2. What are the different types of beaters used in the papermaking process?

- Holland beater: A beater that uses a rotating drum with knives to cut and defiber the pulp

- Claflin beater: A beater that uses a series of rotating cones to defiber the pulp

- Jordan beater: A beater that uses a series of metal bars to defiber the pulp

3. What is the purpose of beating the pulp?

- To separate the fibers and create a uniform fiber suspension

- To improve the bonding strength of the fibers

- To increase the surface area of the fibers

- To reduce the drainage time of the pulp

4. What are the factors that affect the beating process?

- Type of pulp

- Consistency of the pulp

- Temperature of the pulp

- Beating time

- Type of beater

5. How do you determine the optimal beating time for a particular pulp?

The optimal beating time for a particular pulp is determined by conducting a series of tests to evaluate the physical properties of the beaten pulp. These properties include:

- Fiber length

- Fiber strength

- Bonding strength

- Drainage time

6. What are the common problems that can occur during the beating process?

- Overbeating, which can lead to fiber damage

- Underbeating, which can lead to poor paper quality

- Uneven beating, which can lead to variations in paper properties

- Equipment malfunctions

7. How do you troubleshoot and resolve problems with the beating process?

Troubleshooting and resolving problems with the beating process involves the following steps:

- Identifying the problem

- Determining the cause of the problem

- Developing and implementing a solution

- Verifying that the solution has resolved the problem

8. What are the safety precautions that must be followed when operating a beater?

- Wear appropriate protective clothing, including gloves, safety glasses, and a hard hat

- Keep hands and loose clothing away from moving parts

- Do not operate the beater if it is damaged or malfunctioning

- Follow established lockout/tagout procedures

- Be aware of the location of emergency stop buttons

9. What is your experience with quality control in the papermaking process?

In my previous role as a Beater Engineer, I was responsible for implementing and maintaining a comprehensive quality control program for the beating process. This program included the following elements:

- Establishing quality standards for the beaten pulp

- Conducting regular testing of the beaten pulp to ensure compliance with standards

- Identifying and correcting any deviations from standards

- Maintaining records of all quality control data

10. What are your career goals?

My career goals are to continue to develop my skills and knowledge in the papermaking industry. I am particularly interested in learning more about the latest technologies and innovations in the field. I believe that my experience and skills would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beater Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beater Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Beater Engineers play a crucial role in the papermaking process, ensuring the production of high-quality paper from raw materials such as wood pulp and recycled fibers. Their primary responsibilities encompass:

1. Pulp Preparation and Beating

Beater Engineers oversee the preparation and beating of wood pulp or recycled fibers to achieve desired paper properties. They:

- Monitor and control various beating parameters such as time, temperature, and chemical additives to optimize fiber properties.

- Ensure proper hydration and defibering of pulp to achieve the desired strength, softness, and absorbency.

2. Stock Preparation

Beater Engineers are responsible for preparing stock, a mixture of pulp, water, and additives, to meet specific paper requirements. They:

- Calculate and adjust stock composition and consistency to achieve optimal paper quality and runnability.

- Add necessary chemicals and additives to enhance paper properties such as brightness, opacity, and printability.

3. Monitoring and Control

Beater Engineers continuously monitor and control the beating and stock preparation processes to ensure consistency and quality. They:

- Use advanced instrumentation and testing methods to measure and analyze pulp and stock properties.

- Identify and troubleshoot any deviations from desired parameters to maintain optimal production conditions.

4. Equipment Maintenance and Troubleshooting

Beater Engineers are responsible for the maintenance and troubleshooting of beating and stock preparation equipment. They:

- Perform routine maintenance and repairs to ensure equipment reliability and efficiency.

- Troubleshoot and diagnose equipment problems to minimize downtime and maintain production schedules.

Interview Tips

To ace a Beater Engineer interview, candidates should focus on showcasing their technical expertise, problem-solving abilities, and process optimization knowledge. Some essential interview tips include:

1. Research the Industry and Company

Demonstrate a thorough understanding of the papermaking industry and the company’s specific processes. Research their products, technologies, and any recent developments to show your interest and knowledge.

2. Quantify Your Accomplishments

Provide concrete examples of your achievements in previous roles. Use specific metrics and data to quantify your results and highlight your impact on process improvement or cost reduction.

3. Emphasize Troubleshooting Skills

Interviewers will be looking for candidates with strong troubleshooting abilities. Share examples of how you have solved complex equipment or process issues to demonstrate your problem-solving capabilities.

4. Be Prepared for Technical Questions

Be well-versed in the technical aspects of beating and stock preparation. Study concepts such as fiber properties, beating mechanisms, and stock composition to confidently answer questions related to these areas.

5. Ask Insightful Questions

Ask thoughtful questions at the end of the interview to show your interest and engagement. Inquiries about the company’s innovation plans, sustainability initiatives, or career growth opportunities demonstrate your genuine curiosity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Beater Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!