Are you gearing up for a career in Beater Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Beater Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

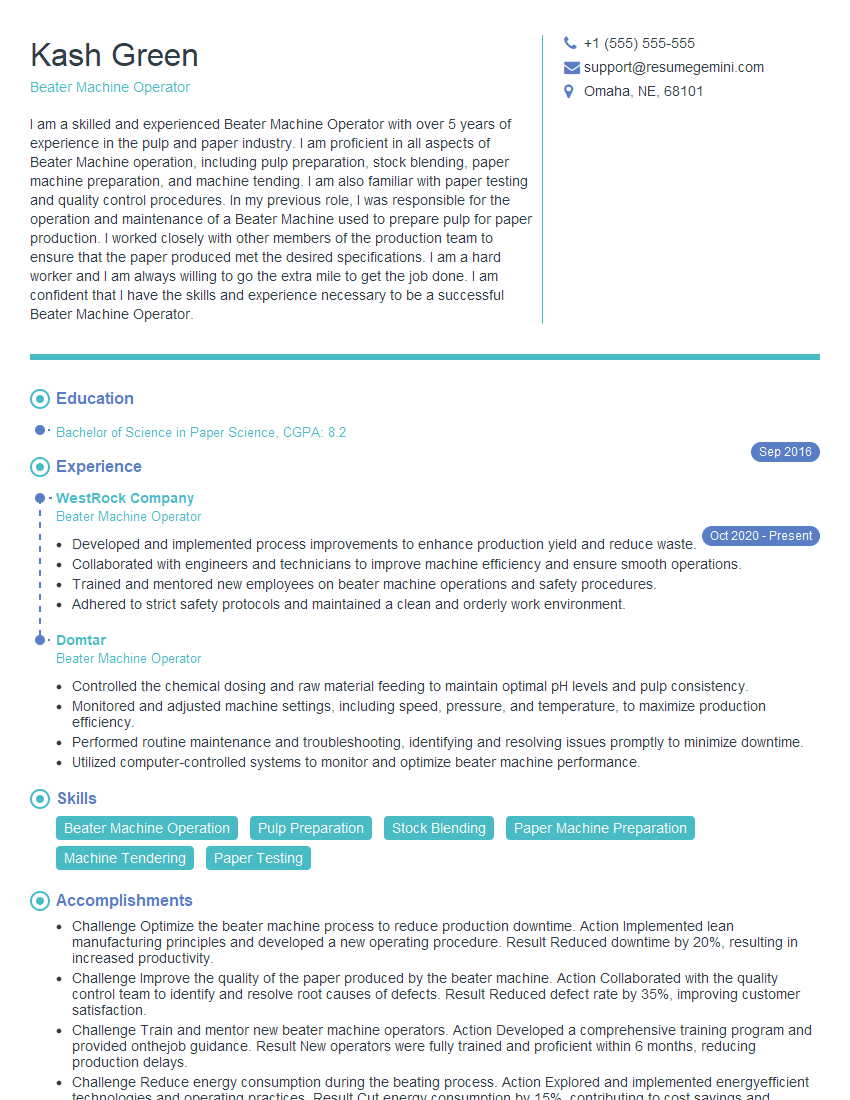

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beater Machine Operator

1. What are your responsibilities as a Beater Machine Operator?

As a Beater Machine Operator, my responsibilities typically include:

- Operating and monitoring beater machines to produce paper pulp

- Adjusting machine settings and adding chemicals to achieve desired pulp quality

- Maintaining and cleaning beater machines to ensure smooth operation

- Monitoring pulp consistency and taking corrective actions as needed

- Following established safety protocols and procedures

2. Can you describe the different types of beater machines and their applications?

Wet Beaters

- Suitable for producing high-quality pulp for fine papers

- Use a roll and bedplate to beat the pulp in the presence of water

Dry Beaters

- Used for producing coarse pulp for packaging and board papers

- Beat the pulp in a dry state using rotating beaters

3. What are the key factors that affect the quality of pulp produced by a beater machine?

- Pulp consistency

- Beating time

- Chemical additives

- Temperature

- Machine settings

4. How do you troubleshoot common problems that may occur with beater machines?

- Pulp quality issues: Adjust machine settings, check chemical additives, or perform maintenance

- Machine breakdowns: Identify and repair mechanical or electrical faults

- Safety hazards: Stop the machine, isolate the hazard, and follow safety protocols

5. What maintenance procedures are necessary for beater machines?

- Regular cleaning and lubrication

- Checking and adjusting belts and gears

- Inspecting and repairing electrical components

- Performing scheduled overhauls for major repairs or replacements

6. How do you ensure the safety of yourself and others while operating beater machines?

- Wearing appropriate PPE (gloves, safety glasses, earplugs)

- Following lockout/tagout procedures

- Being aware of potential hazards and taking precautions

- Reporting any unsafe conditions or incidents

7. What are the different types of raw materials that can be used in a beater machine?

- Wood pulp

- Recycled paper

- Cotton linters

- Straw

- Bagasse

8. How do you calculate the beater power required for a specific production rate?

- Consider the pulp consistency

- Estimate the energy required for beating

- Determine the motor size and speed

- Calculate the power consumption

9. What are the environmental regulations and best practices for operating beater machines?

- Proper waste disposal and treatment

- Minimizing water and energy consumption

- Reducing noise and air pollution

- Adhering to industry standards and safety protocols

10. How do you stay updated on the latest advancements and technologies in the paper industry?

- Attending industry conferences and workshops

- Reading trade publications and technical journals

- Participating in online forums and discussions

- Consulting with experts and vendors

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beater Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beater Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Beater Machine Operator is responsible for operating the beating machine that prepares fibrous materials for paper production. They work in a paper manufacturing plant and carry out tasks such as loading the machine, monitoring the process, and ensuring the quality of the finished product.

1. Operating the Beating Machine

The operator’s primary duty is to operate the beating machine efficiently and safely.

- Loading the machine with raw materials, such as wood pulp, bamboo pulp, or recycled paper.

- Monitoring the beating process, adjusting machine settings as needed to achieve the desired consistency and quality of the pulp.

- Unloading the beaten pulp and transferring it to the next stage of the papermaking process.

2. Maintaining the Beating Machine

The operator is responsible for maintaining the beating machine in good working condition.

- Performing regular cleaning and lubrication of the machine.

- Identifying and reporting any mechanical problems or malfunctions.

- Assisting in repairs and maintenance work as needed.

3. Quality Control

The operator plays a crucial role in ensuring the quality of the finished pulp.

- Inspecting the beaten pulp for consistency, freeness, and other quality parameters.

- Adjusting the beating process or machine settings based on quality control specifications.

- Reporting any quality issues to supervisors or quality control personnel.

4. Safety and Compliance

The operator must adhere to all safety regulations and procedures.

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Following lockout/tagout procedures when performing maintenance or repairs.

- Complying with environmental regulations and waste management practices.

Interview Tips

Preparing for an interview can help you present yourself confidently and make a positive impression on the hiring manager. Here are some tips and hacks to help you ace your Beater Machine Operator interview:

1. Research the Company and Position

Take the time to learn about the company’s history, values, and products. Also, carefully review the job description and identify the key responsibilities and skills required. This will help you tailor your answers and demonstrate your understanding of the role.

2. Highlight Relevant Experience and Skills

In your resume and interview responses, focus on highlighting your experience and skills that are directly relevant to the job. Quantify your accomplishments whenever possible. For example, instead of saying “I operated a beating machine,” say “I operated a beating machine and increased production efficiency by 10%.”

3. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to encounter. Practice answering these questions in advance so that you can deliver clear and concise responses. Some common questions include:

- Tell me about yourself and your experience.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- How do you handle working in a fast-paced environment?

- What are your salary expectations?

4. Prepare Industry-Specific Questions

In addition to general interview questions, you may also be asked industry-specific questions. For the Beater Machine Operator position, some potential questions include:

- What types of beating machines have you worked with?

- How do you control the consistency and quality of the beaten pulp?

- What are the safety precautions that you take when operating the beating machine?

5. Ask Thoughtful Questions

At the end of the interview, the interviewer will likely give you an opportunity to ask questions. This is your chance to show that you are engaged and interested in the position. Ask thoughtful questions about the company, the role, and the industry. For example, you could ask about the company’s plans for future growth or about the latest trends in papermaking technology.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Beater Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.