Are you gearing up for an interview for a Beef Selector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Beef Selector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

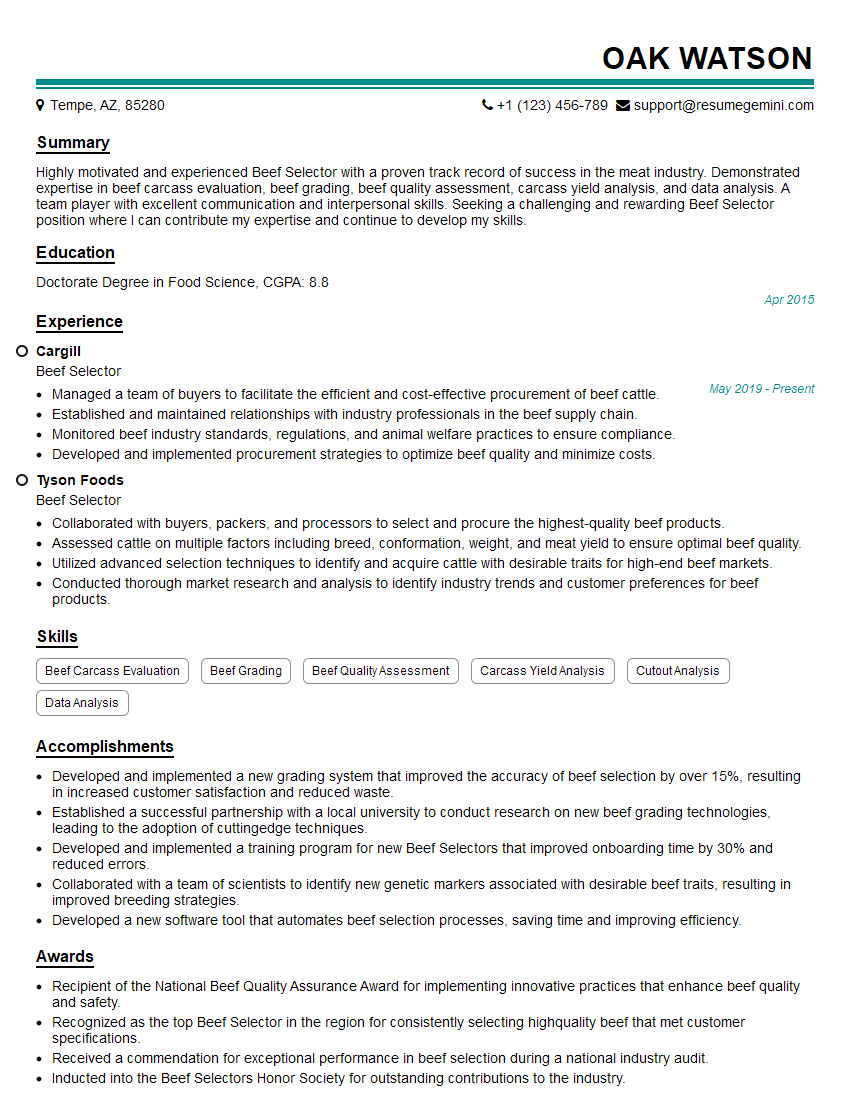

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beef Selector

1. What are the key factors that influence beef quality?

The key factors that influence beef quality are:

- Genetics: The breed of cattle and its genetic makeup can significantly impact the quality of the beef.

- Nutrition: The diet of the cattle, including the type of feed and the grazing conditions, can affect the flavor, tenderness, and overall quality of the meat.

- Age: The age of the cattle at slaughter can influence the tenderness and flavor of the beef.

- Handling: The way the cattle are handled before and during slaughter can affect the quality of the meat.

- Processing: The methods used to process the beef, including the cut of the meat and the aging process, can also impact its quality.

2. How do you assess the marbling and fat content of beef?

Visual assessment

- BMS (Beef Marbling Standard): A numerical scale that rates the amount of marbling in beef from 0 (no marbling) to 10 (abundant marbling).

- IMF (Intramuscular Fat): The percentage of fat within the muscle tissue, which contributes to tenderness and flavor.

Objective assessment

- Near-infrared spectroscopy (NIRS): A non-destructive method that measures the chemical composition of beef, including fat content.

- Ultrasound: A technique that uses sound waves to measure the thickness of the backfat and the intramuscular fat content.

3. What are the different beef grading systems used in the industry?

The major beef grading systems used in the industry include:

- USDA Beef Quality Grades: A system that evaluates the quality of beef based on factors such as marbling, maturity, and firmness.

- EUROP Beef Grading System: A European system that classifies beef carcasses based on their conformation, fat cover, and meat color.

- Japanese Beef Grading System: A highly detailed system that grades beef based on factors such as marbling, color, texture, and yield.

- Australian Meat Standards (AMS): A system that classifies beef carcasses based on their meat quality, fat cover, and conformation.

4. How do you select the best cuts of beef for different culinary purposes?

Selecting the best cuts of beef for different culinary purposes requires considering factors such as:

- Tenderness: Different cuts of beef vary in tenderness, which is influenced by the amount of connective tissue and muscle fibers.

- Flavor: The flavor of beef can vary depending on the cut, with some cuts having a more intense flavor than others.

- Cooking method: The cooking method will determine the appropriate cut of beef, as different cuts are suited for different cooking techniques.

Some examples of popular beef cuts and their culinary applications include:

- Steak cuts (e.g., ribeye, striploin, tenderloin): Grilled, roasted, or pan-seared for maximum tenderness and flavor.

- Roasting cuts (e.g., prime rib, sirloin tip): Roasted in the oven for a tender and juicy roast.

- Ground beef (e.g., chuck, round): Used in burgers, meatballs, and other dishes where a ground meat texture is desired.

5. What are the common defects or quality issues that can occur in beef production?

- Dark cutters: Beef with a dark, reddish-brown color due to high levels of myoglobin, which can affect its appearance and flavor.

- PSE (Pale, Soft, Exudative): Beef that is pale in color, soft in texture, and has excessive water loss, resulting in a lower quality product.

- DFD (Dark, Firm, Dry): Beef that is dark in color, firm in texture, and has reduced water-holding capacity, leading to a tough and dry eating experience.

- BSE (Bovine Spongiform Encephalopathy): A fatal neurological disease in cattle, also known as “mad cow disease,” which can contaminate the meat and pose a health risk.

6. What are the best practices for storing and preserving beef to maintain its quality?

- Temperature control: Beef should be stored at a temperature of 32°F (0°C) or below to inhibit bacterial growth and preserve its quality.

- Vacuum packaging: Vacuum-packaging beef removes oxygen from the package, which helps prevent spoilage and extends its shelf life.

- Controlled atmosphere storage: Beef can be stored in a controlled atmosphere with reduced oxygen and increased carbon dioxide levels to slow down the aging process and maintain its freshness.

- Freezing: Freezing beef at -18°F (-28°C) or below can significantly extend its shelf life, but it’s essential to thaw it properly before cooking to preserve its quality.

7. What are the key trends and innovations in the beef industry?

- Sustainability: Consumers are increasingly demanding beef produced in a sustainable manner, with a focus on animal welfare, environmental conservation, and reduced emissions.

- Precision agriculture: The use of technology to optimize beef production practices, such as monitoring cattle health and growth, improving feed efficiency, and reducing environmental impact.

- Cell-cultured beef: The development of lab-grown beef as an alternative protein source, offering potential benefits in terms of sustainability and animal welfare.

- E-commerce and direct-to-consumer sales: The growing trend of consumers purchasing beef directly from farmers and online retailers, offering greater transparency and convenience.

8. What are the emerging technologies being used in beef production and processing?

- Artificial intelligence (AI): AI-powered systems are used for tasks such as predicting cattle growth, optimizing feeding strategies, and identifying health issues.

- Blockchain technology: Blockchain is used to track the movement and history of beef throughout the supply chain, enhancing transparency and traceability.

- Automated grading systems: Automated systems use computer vision and machine learning to grade beef carcasses based on quality and yield parameters.

- Advanced packaging technologies: New packaging technologies, such as modified atmosphere packaging (MAP) and active packaging, help extend the shelf life and maintain the quality of beef products.

9. How do you stay updated on the latest advancements and industry best practices in beef production?

- Attending industry conferences and workshops

- Reading scientific journals and publications

- Participating in industry organizations and networking with professionals

- Consulting with experts and researchers

- Utilizing online resources and platforms

10. How would you contribute to our efforts to enhance beef quality and production efficiency?

I would leverage my expertise in beef selection, grading, and processing to:

- Implement rigorous quality control measures at every stage of production

- Optimize cattle nutrition and feeding strategies to enhance meat quality

- Utilize advanced technologies for objective beef assessment and precision production

- Stay abreast of industry best practices and implement innovative solutions to improve efficiency

- Collaborate with stakeholders throughout the supply chain to ensure a consistent and high-quality beef product

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beef Selector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beef Selector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Beef selectors play a crucial role in the meat industry by evaluating and selecting high-quality beef carcasses for processing and distribution. Their responsibilities include:

1. Carcasses Evaluation

Assess beef carcasses based on USDA grading standards, including factors such as weight, conformation, marbling, and fat cover to determine their quality and value.

2. Selection and Grading

Select carcasses that meet specific specifications and grades for different markets and customers based on quality attributes and industry standards.

3. Monitoring Slaughterhouse Operations

Observe the slaughtering process to ensure proper handling and carcass quality. Identify and address any issues that may affect meat safety or quality.

4. Carcass Data Analysis

Collect and analyze data on carcass characteristics, such as weight, fat content, marbling, and yield, to provide insights into production trends and improve selection decisions.

5. Customer Communication

Communicate with customers, including buyers and retailers, to provide information on carcass availability, quality, and pricing.

Interview Tips

To ace the interview for a Beef Selector position, it is essential to prepare thoroughly. Here are some key tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and market position. Understand the current trends and challenges in the meat industry.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions related to your experience, skills, and knowledge of beef grading and selection. Use the STAR method (Situation, Task, Action, Result) to structure your responses.

3. Highlight Your Industry Knowledge

Demonstrate your expertise in beef grading standards, carcass evaluation techniques, and industry regulations. Discuss your experience in selecting carcasses based on different quality criteria.

4. Emphasize Your Communication and Teamwork Skills

Communicating effectively with buyers and other stakeholders is crucial. Highlight your ability to build relationships and collaborate with teams to achieve goals.

5. Bring a Positive Enthusiasm

Showcase your passion for the meat industry and your desire to contribute to the company’s success. Express your enthusiasm for working with beef carcasses and your dedication to delivering high-quality products.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Beef Selector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!