Are you gearing up for a career in Beer Brewer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Beer Brewer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

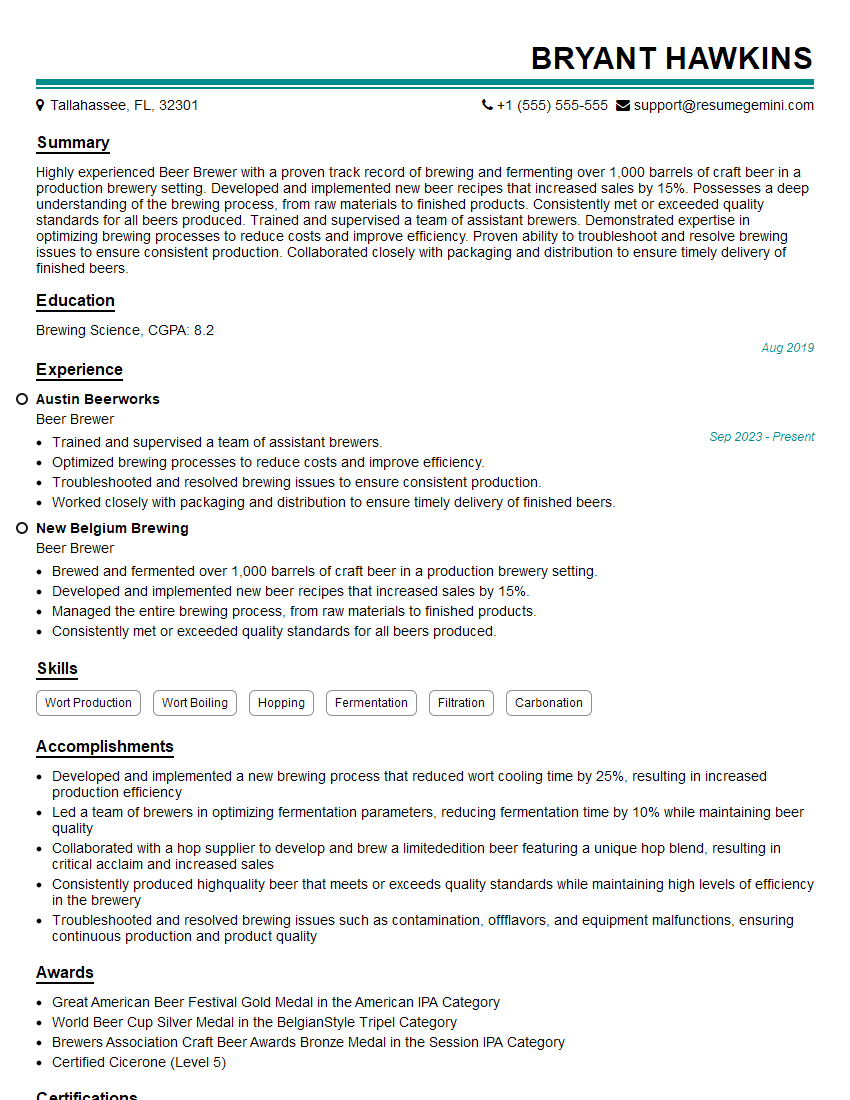

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beer Brewer

1. What are the key ingredients used in brewing beer?

The key ingredients used in brewing beer are:

- Water

- Malted barley

- Hops

- Yeast

2. What is the role of yeast in the brewing process?

Fermentation

- Yeast is a fungus that converts the sugars in wort into alcohol and carbon dioxide through a process called fermentation.

- The type of yeast used will determine the style and flavor of the beer.

Attenuation

- Yeast also plays a role in attenuation, which is the measure of how much sugar is converted into alcohol.

- Higher attenuation results in a drier beer, while lower attenuation results in a sweeter beer.

3. Describe the different types of hops and their impact on beer flavor.

Hops are used to provide bitterness, aroma, and flavor to beer. There are many different varieties of hops, each with its own unique characteristics:

- Bittering hops: Used to add bitterness to beer. Typically added early in the boil.

- Aroma hops: Used to add aroma and flavor to beer. Typically added late in the boil or during fermentation.

- Dry hops: Added after fermentation to enhance aroma and flavor.

4. What is the purpose of mashing in the brewing process?

Mashing is the process of converting the starches in malted barley into fermentable sugars. This is done by mixing the malted barley with hot water and holding it at a specific temperature for a period of time.

- The enzymes in the malted barley break down the starches into sugars, which are then available for the yeast to ferment.

- The temperature of the mash will determine the type of sugars that are produced, which will in turn affect the flavor of the beer.

5. How do you control the fermentation temperature to achieve the desired beer style?

Fermentation temperature is critical to controlling the flavor and aroma of beer. Different yeast strains ferment at different temperatures, and the temperature will also affect the rate of fermentation.

- Ale yeasts: Ferment at warmer temperatures (60-75°F), producing beers with fruity and ester-rich flavors.

- Lager yeasts: Ferment at cooler temperatures (45-55°F), producing beers with cleaner and crisper flavors.

- Temperature control: Breweries use temperature-controlled fermentation vessels to maintain the desired fermentation temperature.

6. What is the importance of sanitation in the brewing process?

Sanitation is crucial in the brewing process to prevent contamination and spoilage. Bacteria and other microorganisms can contaminate beer at any stage of the brewing process, resulting in off-flavors, spoilage, and even illness.

- Breweries implement strict sanitation protocols to ensure that all equipment, ingredients, and surfaces are clean and free of contaminants.

- Sanitation measures include regular cleaning and disinfection of equipment, proper handling of ingredients, and maintaining a hygienic brewing environment.

7. Describe the different types of beer filtration and their effects on beer clarity and stability.

Beer filtration is used to remove solids and impurities from beer. Filtration can be done using different methods, each with its own effects on beer clarity and stability:

- Depth filtration: Uses a filter bed to remove particles from beer. This method provides good clarity but can remove some flavor compounds.

- Membrane filtration: Uses a semi-permeable membrane to filter beer. This method provides excellent clarity and removes most microorganisms.

- Centrifugation: Uses a centrifuge to separate solids from beer. This method is less effective at removing small particles but can be used to remove larger particles and sediment.

8. How do you calculate the original gravity (OG) and final gravity (FG) of beer?

Original gravity (OG) and final gravity (FG) are measurements of the specific gravity of beer. OG is measured before fermentation, while FG is measured after fermentation. These measurements are used to calculate the alcohol content of beer:

- OG: Measured using a hydrometer. Indicates the amount of fermentable sugars present in the wort.

- FG: Measured after fermentation is complete. Indicates the amount of fermentable sugars that have been converted into alcohol.

- Alcohol content: Calculated using the following formula: Alcohol content (%) = (OG – FG) x 131.25

9. What are the common challenges faced in beer brewing and how do you overcome them?

Common challenges in beer brewing include:

- Contamination: Maintaining a sterile environment and following good sanitation practices are essential to prevent contamination.

- Temperature control: Different yeast strains require specific fermentation temperatures. Breweries use fermentation vessels with temperature control to maintain optimal conditions.

- Equipment malfunctions: Regular maintenance and preventative measures are necessary to minimize equipment failures that could disrupt the brewing process.

- Ingredient quality: Using high-quality ingredients is crucial for producing great beer. Brewers work closely with suppliers to ensure the quality of raw materials.

10. What are the key quality control measures implemented in a brewery?

Breweries implement a range of quality control measures to ensure the consistency and quality of their beer:

- Raw material testing: Ingredients are tested for quality and consistency before being used in brewing.

- In-process monitoring: Various parameters are monitored during the brewing process, such as temperature, pH, and specific gravity.

- Sensory evaluation: Trained panelists evaluate the beer’s appearance, aroma, flavor, and mouthfeel to ensure it meets quality standards.

- Microbiological testing: Beer is tested for microorganisms to ensure it is free from contamination.

- Packaging integrity: Packaging is inspected to ensure it is free from defects and will protect the beer from spoilage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beer Brewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beer Brewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Craft beer brewers are responsible for all aspects of beer production, from the recipe design to the final packaging. They must have a strong understanding of the brewing process, as well as the ability to operate and maintain brewing equipment. Some of the key job responsibilities of a craft beer brewer include:

1. Recipe Development

Craft beer brewers are responsible for creating and testing new beer recipes. They must have a good understanding of the different ingredients used in brewing, as well as the different brewing methods. They must also be able to adjust recipes to account for the specific characteristics of the water and other ingredients used in the brewing process.

2. Brewing

Craft beer brewers are responsible for brewing the beer according to the recipe. They must be able to operate and maintain brewing equipment, as well as monitor the brewing process to ensure that the beer is brewed to the correct specifications.

3. Fermentation and Aging

Craft beer brewers are responsible for fermenting and aging the beer. They must be able to control the fermentation process to ensure that the beer develops the desired flavor and aroma. They must also be able to age the beer for the correct amount of time to achieve the desired results.

4. Packaging and Distribution

Craft beer brewers are responsible for packaging and distributing the finished beer. They must be able to choose the right packaging materials and methods to ensure that the beer is protected from spoilage. They must also be able to coordinate with distributors to ensure that the beer is delivered to customers in a timely and efficient manner.

Interview Tips

Preparing for an interview for a craft beer brewer position can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Brewery

Before you go to your interview, take some time to research the brewery. This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can find information about the brewery on their website, in their social media accounts, and in online articles.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Why do you want to work for our brewery?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in brewing beer. Be prepared to talk about your previous experience, including the types of beer you have brewed, the equipment you have used, and the challenges you have faced. You should also be able to discuss your knowledge of the brewing process and your passion for beer.

4. Be Enthusiastic and Passionate

Brewers are often passionate about their work. If you are passionate about beer and brewing, let the interviewer know. Your enthusiasm will show through in your interview and will help you to stand out from other candidates.

5. Dress Professionally

First impressions matter. When you go to your interview, dress professionally. This will show the interviewer that you are serious about the position and that you respect the company.

Next Step:

Now that you’re armed with the knowledge of Beer Brewer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Beer Brewer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini