Feeling lost in a sea of interview questions? Landed that dream interview for Beet Topper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Beet Topper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

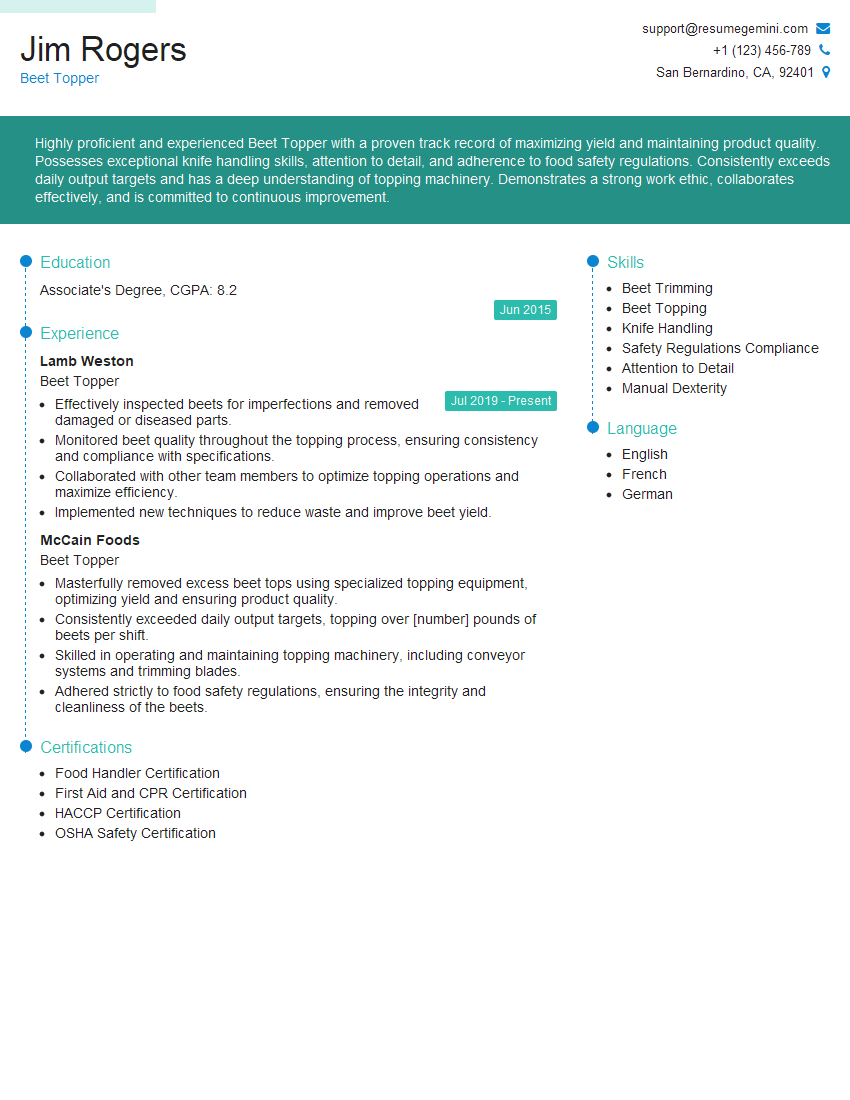

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beet Topper

1. What are the most important factors to consider when selecting beet varieties for processing?

- Variety yield potential

- Beet size and shape

- Sugar content

- Disease resistance

- Storage quality

2. How do you determine the optimum harvest maturity of beets?

subheading of the answer

- Physiological maturity indicators (e.g., leaf senescence, root diameter)

- Sugar content analysis

- Harvesting equipment limitations

subheading of the answer

- Impact on processing efficiency

- Storage potential of beets

- Environmental conditions

3. Describe the different methods of topping beets and their respective advantages and disadvantages.

- Mechanical topping:

- Advantages: Fast, efficient

- Disadvantages: Can damage beets, inconsistent cuts

- Hand topping:

- Advantages: Precise, minimizes damage

- Disadvantages: Slow, labor-intensive

- Chemical topping:

- Advantages: Non-mechanical, reduces damage

- Disadvantages: Potential environmental concerns, may affect processing

4. What are the key factors that affect the storage quality of topped beets?

- Harvest maturity

- Topping method

- Storage temperature and humidity

- Disease and pest control

- Airflow and ventilation

5. How do you minimize sugar losses during beet processing?

- Optimizing harvest timing and storage conditions

- Efficient extraction and juice clarification

- Minimizing heating and evaporation

- Controlling pH and temperature

- Using efficient filtration systems

6. What are the common challenges encountered in beet topping operations and how do you address them?

- Inconsistent topping height: Adjust equipment settings, train operators

- Damage to beets: Use sharp blades, reduce topping speed

- Yield loss: Optimize harvest timing, minimize topping height

- Labor shortages: Automate or semi-automate topping operations

- Environmental conditions: Adjust topping settings based on weather, use protective measures

7. Describe the role of technology in improving beet topping efficiency and quality.

- Automated topping equipment: Consistent cuts, reduced labor

- Sensors and image analysis: Optimizing topping height, minimizing damage

- Data analytics: Tracking key performance indicators, identifying areas for improvement

- Remote monitoring and control: Real-time adjustment of topping operations

- Artificial intelligence: Predictive maintenance, quality control

8. How do you ensure the optimal performance of beet topping equipment?

- Regular maintenance and inspection

- Calibrating and adjusting settings

- Training operators on proper usage

- Monitoring equipment performance and addressing issues promptly

- Seeking support from equipment manufacturers and service providers

9. What are your strategies for minimizing downtime during beet topping operations?

- Preventive maintenance and regular inspections

- Maintaining spare parts and equipment

- Cross-training staff on multiple tasks

- Collaborating with suppliers and service providers for rapid response

- Implementing automated monitoring systems to identify potential issues early

10. Describe your experience in working with beet growers and processors.

- Collaborated with growers to optimize variety selection, planting practices, and harvest timing

- Assisted processors in developing and implementing efficient topping and processing systems

- Participated in research and development projects to improve beet quality and yield

- Provided consultation and training on beet topping best practices

- Built strong relationships with key stakeholders in the beet industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beet Topper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beet Topper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Beet Topper plays a crucial role in the food processing industry, overseeing the efficient and precise removal of beet tops from harvested beets. This highly specialized position demands a meticulous attention to detail, proficiency in operating topping machinery, and a deep understanding of beet harvesting processes.

1. Beet Preparation and Topping

Prior to topping, the Beet Topper inspects and prepares beets for uniform feeding into the topping machine. They monitor beet flow, adjust equipment settings, and make necessary adjustments to ensure consistent and optimal topping results.

2. Equipment Operation and Maintenance

The Beet Topper operates and maintains beet topping machinery, including clippers, toppers, and conveyors. They perform routine inspections, lubrication, and repairs to keep the equipment in peak condition, minimizing downtime and ensuring smooth operation.

3. Quality Control and Waste Management

The Beet Topper ensures the quality of topped beets by conducting thorough inspections and adhering to predetermined specifications. They identify and remove any damaged, rotten, or undersized beets, preventing contamination and maintaining product integrity. Additionally, they manage waste materials generated during the topping process, ensuring compliance with environmental regulations.

4. Adherence to Safety Protocols

Working in a food processing environment requires strict adherence to safety protocols. The Beet Topper follows all established safety guidelines, including wearing appropriate protective gear, maintaining a clean and organized work area, and promptly reporting any potential hazards.

Interview Tips

To prepare effectively for a Beet Topper interview, candidates should consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the food processing industry. Research the company’s values, products, and market position. Understand industry trends and challenges to showcase your understanding of the context in which the role operates.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating topping machinery, maintaining food processing equipment, and adhering to safety protocols. Quantify your accomplishments with specific examples to illustrate your proficiency in these areas.

3. Emphasize Attention to Detail and Quality

The Beet Topper role requires a meticulous eye for detail and a commitment to quality. During the interview, highlight your ability to inspect beets thoroughly, identify defects, and maintain high standards throughout the topping process.

4. Demonstrate Teamwork and Communication Skills

In food processing environments, teamwork and effective communication are essential. Explain how you have worked successfully in a team setting, collaborated with others, and resolved issues promptly. Share examples of clear and concise communication in a production environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Beet Topper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!