Are you gearing up for a career in Belt and Link Assembly Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Belt and Link Assembly Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

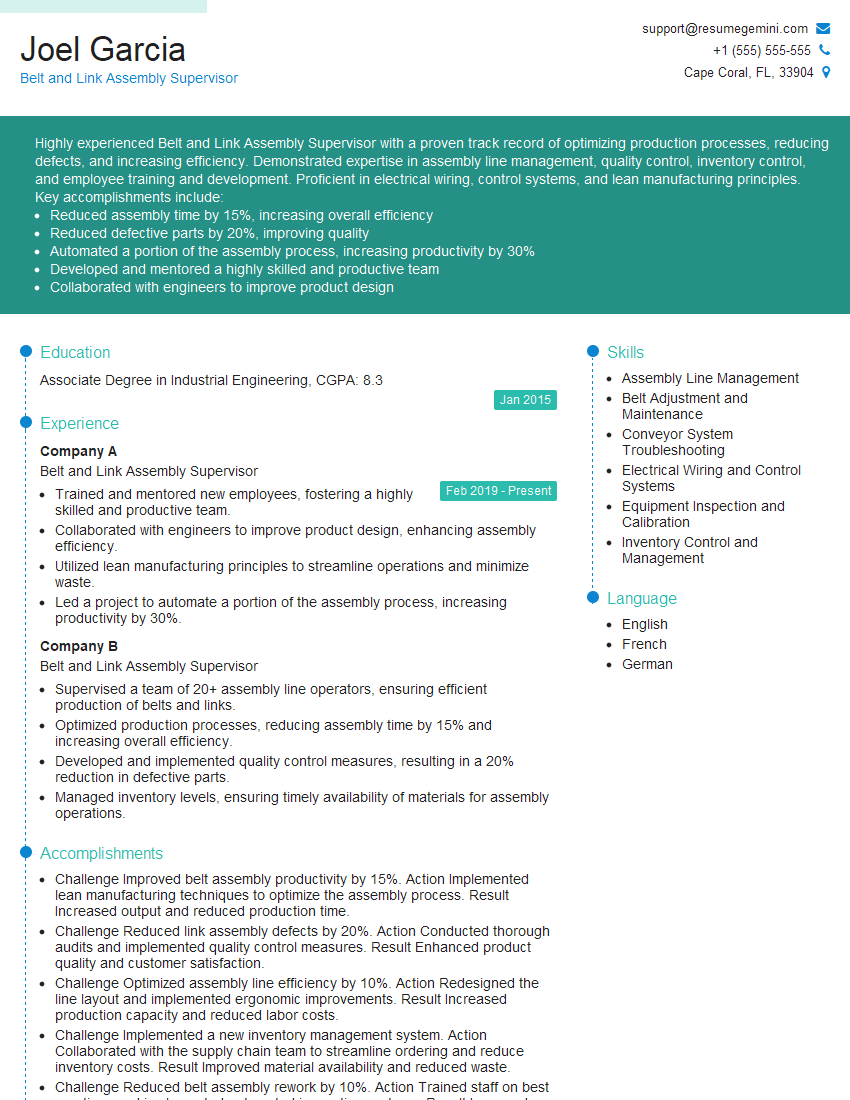

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt and Link Assembly Supervisor

1. What are the key performance indicators (KPIs) you would use to measure the success of a belt and link assembly operation?

I would use a combination of performance indicators such as:

- OEE (Overall Equipment Effectiveness): This metric measures the overall effectiveness of the assembly operation, taking into account factors such as availability, performance, and quality.

- First-pass yield: This metric measures the percentage of assemblies that pass quality inspection on the first attempt.

- Throughput: This metric measures the number of assemblies produced per hour.

- Defect rate: This metric measures the percentage of assemblies that are rejected due to defects.

- Cycle time: This metric measures the average time it takes to assemble a single belt and link.

2. Describe the steps involved in the belt and link assembly process.

The belt and link assembly process typically involves the following steps:

- Prepare the materials: This includes gathering the necessary belts, links, and other components.

- Assemble the belt: This involves attaching the links to the belt using a press or other tool.

- Inspect the belt: This involves checking the belt for any defects or errors.

- Package the belt: This involves placing the belt in a protective packaging material.

3. What are the common challenges faced in belt and link assembly operations?

- Material shortages: This can occur due to factors such as supply chain disruptions or quality issues.

- Equipment breakdowns: This can cause delays in production and increase the risk of defects.

- Quality issues: This can occur due to factors such as improper assembly or the use of defective materials.

- Safety hazards: This includes risks such as cuts, bruises, and eye injuries.

- Ergonomic issues: This includes repetitive motions and awkward postures that can lead to fatigue and discomfort.

4. How would you improve the efficiency of a belt and link assembly operation?

To improve the efficiency of a belt and link assembly operation, I would:

- Implement lean manufacturing principles: This includes techniques such as 5S, kaizen, and kanban.

- Automate processes: This includes using machines to perform repetitive tasks, such as assembling and inspecting belts.

- Improve training: This includes providing employees with the skills and knowledge they need to perform their jobs effectively.

- Empower employees: This includes giving employees the authority to make decisions and solve problems.

- Create a positive work environment: This includes providing employees with a safe, healthy, and supportive work environment.

5. What are your quality control procedures for ensuring the quality of belt and link assemblies?

My quality control procedures for ensuring the quality of belt and link assemblies include:

- Visual inspection: This involves visually inspecting belts and links for any defects or errors.

- Dimensional inspection: This involves using measuring tools to check the dimensions of belts and links.

- Functional testing: This involves testing belts and links to ensure that they meet the required specifications.

- Statistical process control (SPC): This involves using statistical methods to monitor and control the quality of the assembly process.

6. How do you manage a team of belt and link assemblers?

To manage a team of belt and link assemblers, I would:

- Set clear goals and expectations: This includes communicating the team’s goals and objectives to each member.

- Provide training and support: This includes providing employees with the skills and knowledge they need to perform their jobs effectively.

- Empower employees: This includes giving employees the authority to make decisions and solve problems.

- Create a positive work environment: This includes providing employees with a safe, healthy, and supportive work environment.

- Monitor performance: This includes tracking the team’s progress and identifying areas for improvement.

7. What are your safety procedures for working in a belt and link assembly operation?

My safety procedures for working in a belt and link assembly operation include:

- Wearing appropriate personal protective equipment (PPE): This includes items such as safety glasses, gloves, and hearing protection.

- Following lockout/tagout procedures: This involves isolating and de-energizing equipment before performing maintenance or repairs.

- Using proper lifting techniques: This includes using proper body mechanics to avoid injuries.

- Being aware of potential hazards: This includes being aware of trip hazards, pinch points, and other potential dangers.

- Reporting any unsafe conditions or practices: This includes reporting any hazards to the supervisor or safety manager.

8. How do you stay up-to-date on the latest trends in belt and link assembly technology?

- Reading industry publications: This includes reading trade magazines and journals.

- Attending industry events: This includes attending conferences and trade shows.

- Networking with other professionals: This includes connecting with other belt and link assembly professionals through online forums and social media.

- Taking continuing education courses: This includes taking courses on the latest belt and link assembly technologies.

9. What are your career goals?

My career goals are to

- Become a recognized expert in the field of belt and link assembly,

- Lead a team of belt and link assemblers to achieve world-class quality and productivity,

- Develop new and innovative belt and link assembly technologies,

- Make a significant contribution to the field of belt and link assembly,

- Become a respected leader in the manufacturing industry.

10. Why are you interested in working for our company?

I am interested in working for your company because it is a

- Leader in the belt and link assembly industry,

- Has a reputation for quality and innovation,

- Offers opportunities for professional growth and development,

- Has a strong commitment to safety,

- Is a great place to work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt and Link Assembly Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt and Link Assembly Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Belt and Link Assembly Supervisor

The Belt and Link Assembly Supervisor is responsible for overseeing the production of belts and links, ensuring that they meet quality standards and production targets. Key responsibilities include:

1. Production Planning and Scheduling

The supervisor plans and schedules production activities, including determining production runs, assigning staff, and allocating resources.

- Estimate production time and resources required

- Schedule production runs to optimize efficiency

2. Quality Control

The supervisor ensures that belts and links meet quality standards by implementing and maintaining quality control procedures.

- Inspect belts and links for defects

- Identify and resolve quality issues

- Maintain quality control documentation

3. Employee Supervision

The supervisor leads and motivates a team of assembly workers, providing training, guidance, and performance evaluations.

- Train and supervise assembly workers

- Monitor employee performance

- Provide feedback and coaching

4. Equipment Maintenance

The supervisor ensures that assembly equipment is properly maintained and calibrated to maximize productivity.

- Inspect and maintain assembly equipment

- Identify and resolve equipment issues

- Coordinate with maintenance personnel

Interview Preparation Tips for Belt and Link Assembly Supervisor

To ace an interview for a Belt and Link Assembly Supervisor position, candidates should:

1. Research the Company and Position

Learn about the company’s history, products, and industry. Review the job description carefully and identify key responsibilities and requirements.

- Visit the company website

- Read industry news and articles

- Connect with current or former employees on LinkedIn

2. Prepare Examples of Success

Use the STAR method (Situation, Task, Action, Result) to prepare specific examples that demonstrate your skills and experience. Focus on accomplishments related to production planning, quality control, employee supervision, and equipment maintenance.

- Describe a situation where you successfully planned and executed a major production run

- Explain how you implemented a quality control program that significantly reduced defects

- Share an example of how you motivated and developed your team to achieve high performance

3. Practice Your Answers

Rehearse your answers to common interview questions. This will help you feel more confident and articulate your thoughts clearly during the interview.

- Prepare answers to questions about your experience, skills, and qualifications

- Practice answering questions about your leadership style and approach to problem-solving

- Have questions ready to ask the interviewer

4. Dress Professionally and Be Punctual

Make a good first impression by dressing professionally and arriving for the interview on time. Your appearance and punctuality convey respect and seriousness about the position.

- Wear a clean, pressed suit or business casual attire

- Arrive at the interview location a few minutes early

- Bring a portfolio or folder with copies of your resume and relevant certifications

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Belt and Link Assembly Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!