Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Belt Conveyor Drier interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Belt Conveyor Drier so you can tailor your answers to impress potential employers.

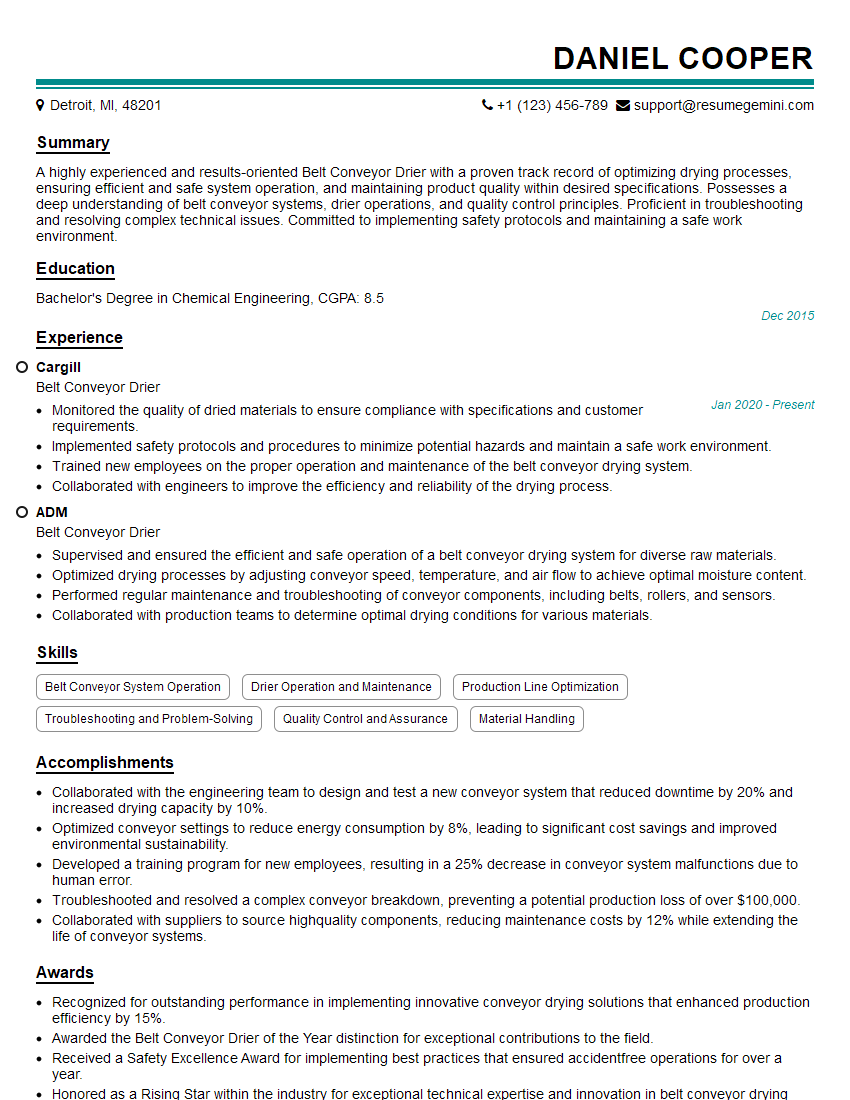

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt Conveyor Drier

1. What are the key components of a belt conveyor drier?

- Conveyor belt

- Drying chamber

- Heating system

- Exhaust system

- Control system

2. How does a belt conveyor drier work?

Drying Process

- Wet material is fed onto the conveyor belt.

- The belt moves the material through the drying chamber.

- Hot air is circulated around the material, evaporating the moisture.

- The dried material is discharged from the conveyor belt.

Heating System

- Gas burners or electric heaters provide heat for the drying process.

- The temperature of the heating system is controlled to ensure efficient drying.

Exhaust System

- An exhaust system removes the moisture-laden air from the drying chamber.

- The exhaust air is treated to remove pollutants before being released into the atmosphere.

Control System

- A control system monitors and adjusts the operation of the drier.

- The control system ensures that the drying process is optimized for efficiency and product quality.

3. What are the factors that affect the drying efficiency of a belt conveyor drier?

- Material properties (moisture content, particle size, density)

- Drying temperature

- Airflow rate

- Belt speed

- Conveyor belt length

- Drying chamber design

4. What are the common problems associated with belt conveyor driers and how can they be solved?

- Problem: Material sticking to the belt

Solution: Use a non-stick belt material or apply a release agent. - Problem: Uneven drying

Solution: Adjust the airflow distribution or conveyor belt speed. - Problem: Overheating of the material

Solution: Reduce the drying temperature or increase the airflow rate. - Problem: Corrosion of the conveyor belt

Solution: Use a corrosion-resistant belt material or apply a protective coating.

5. What are the maintenance requirements for a belt conveyor drier?

- Regular inspection of the conveyor belt and heating system

- Cleaning of the drying chamber and exhaust system

- Lubrication of moving parts

- Calibration and adjustment of the control system

6. What are the safety precautions that should be taken when operating a belt conveyor drier?

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Be aware of the potential for hot surfaces and moving machinery.

- Do not enter the drying chamber while the drier is in operation.

- Ensure that the exhaust system is operating properly.

7. What is the difference between a single-pass and a multi-pass belt conveyor drier?

- Single-pass drier: Material passes through the drying chamber only once.

- Multi-pass drier: Material passes through the drying chamber multiple times, allowing for more efficient drying.

8. What are the advantages and disadvantages of using a belt conveyor drier compared to other types of driers?

Advantages:

- Continuous operation

- High drying efficiency

- Suitable for a wide range of materials

- Compact design

Disadvantages:

- High initial investment cost

- Requires skilled operators

- Can be noisy

9. What is the role of a variable frequency drive (VFD) in a belt conveyor drier?

- Controls the speed of the conveyor belt

- Optimizes the drying process by adjusting the belt speed based on the material properties and drying conditions

- Reduces energy consumption by operating the belt at the most efficient speed

10. What are the emerging trends in belt conveyor drier technology?

- Development of more energy-efficient designs

- Integration of automation and control systems

- Use of advanced materials to improve durability and performance

- Adoption of artificial intelligence (AI) techniques for process optimization

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt Conveyor Drier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt Conveyor Drier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Belt Conveyor Drier is responsible for the efficient and safe operation of conveyor driers in a manufacturing environment. Their primary tasks revolve around maintaining, monitoring, and troubleshooting these machines to ensure optimal performance and product quality. Key responsibilities include:

1. Machine Operation and Maintenance

Operates conveyor driers according to established procedures and safety regulations.

- Monitors and adjusts machine settings, such as temperature, speed, and tension, to achieve desired drying results.

- Conducts routine maintenance on conveyor driers, including cleaning, lubrication, and minor repairs.

2. Product Quality Control

Ensures that products passing through the conveyor driers meet quality specifications.

- Inspects products for defects, such as moisture content, color, and size.

- Adjusts machine settings and makes necessary adjustments to maintain product quality.

3. Troubleshooting and Problem Solving

Identifies and resolves problems that occur during the drying process.

- Diagnoses malfunctions and makes repairs as needed.

- Consults with technical experts or supervisors for assistance when necessary.

4. Safety and Compliance

Maintains a safe and compliant work environment.

- Adheres to all safety protocols and regulations.

- Wears appropriate personal protective equipment (PPE) and follows safe work practices.

Interview Tips

To ace an interview for a Belt Conveyor Drier position, it’s essential to prepare thoroughly. Here are some helpful tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and specific requirements for the Belt Conveyor Drier role. This knowledge will help you tailor your answers to demonstrate your alignment with their needs.

- Visit the company’s website and social media pages.

- Read industry publications and articles to gain insights into current trends and best practices.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your technical skills and experience that are directly applicable to the role. Quantify your accomplishments and provide specific examples to showcase your capabilities.

- Provide details about your experience in operating and maintaining conveyor driers.

- Describe your problem-solving abilities and successful troubleshooting experiences.

3. Show Enthusiasm and Passion

Convey your enthusiasm for the role and your passion for maintaining and optimizing production processes. Express your eagerness to contribute to the company’s success through your dedication and expertise.

- Discuss your interest in the company’s products or services.

- Explain how your skills and experience can support the company’s objectives.

4. Prepare Questions for the Interviewer

Prepare thoughtful questions to ask the interviewer about the role, the team, and the company’s culture. This demonstrates your interest and engagement in the interview process.

- Inquire about the company’s growth plans and how the role contributes to those goals.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Belt Conveyor Drier role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.