Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Belt Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

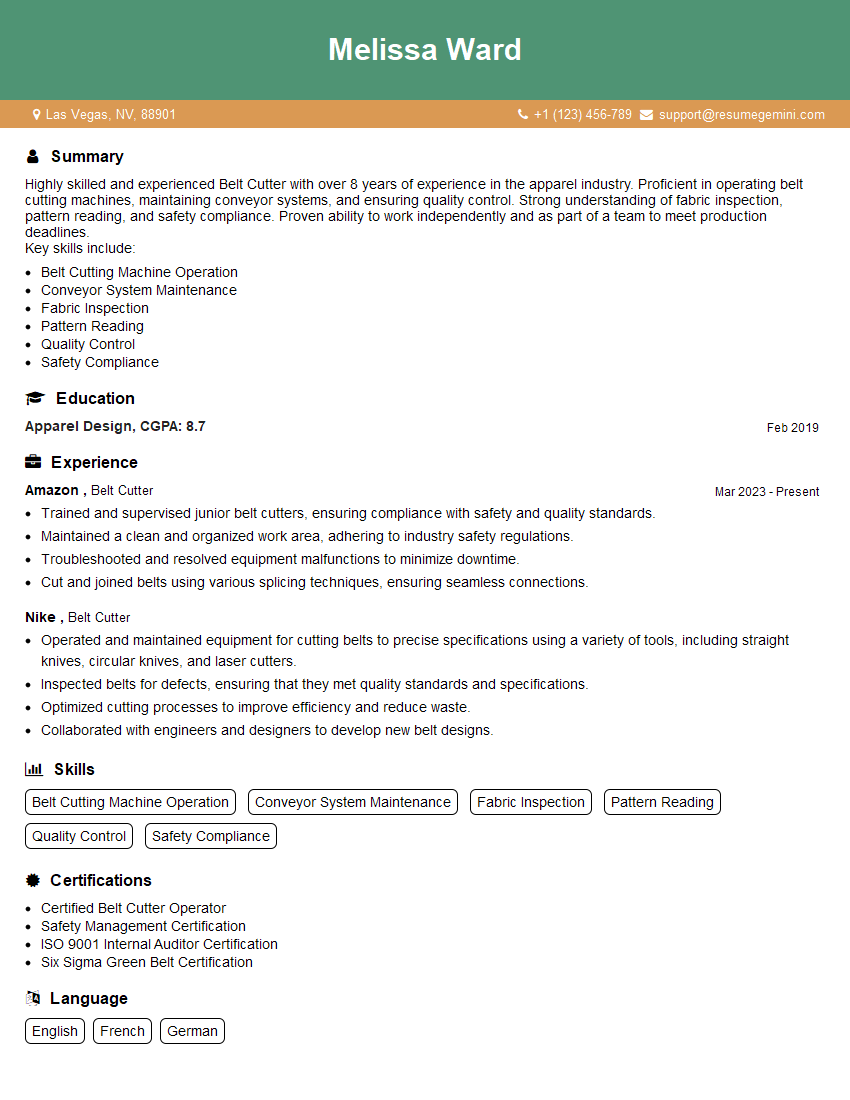

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt Cutter

1. If a belt cutter machine is not cutting straight, which areas can be examined to solve the issue?

There are various reasons that can cause a belt cutter machine to not cut straight. Some potential areas to examine include:

- Blade sharpness: A dull blade will not cut cleanly and may cause the belt to tear or fray.

- Blade alignment: The blade must be properly aligned with the cutting surface to ensure a straight cut.

- Belt tension: The belt should be properly tensioned to prevent it from slipping or stretching during the cutting process.

- Material thickness: The machine may not be suitable for cutting belts of certain thicknesses.

- Cutting surface: The cutting surface should be flat and clean to ensure a smooth cut.

2. Explain the importance of regular maintenance for a belt cutter machine.

Benefits of regular maintenance:

- Extended machine life: Regular maintenance helps prevent unexpected breakdowns and prolongs the machine’s lifespan.

- Improved cutting accuracy: Regular maintenance ensures that the machine’s components are working optimally, resulting in more precise cuts.

- Increased productivity: A well-maintained machine operates smoothly and efficiently, leading to increased productivity.

- Reduced downtime: Regular maintenance helps identify and address potential issues before they escalate into major problems, minimizing downtime.

- Enhanced safety: A properly maintained machine operates safely, reducing the risk of accidents or injuries.

3. Describe the different types of belts that can be cut using a belt cutter machine.

Belt cutter machines can handle a variety of belt types, including:

- Conveyor belts: Used in industrial applications to transport materials.

- Timing belts: Used in automotive and other mechanical systems to synchronize movement.

- V-belts: Used in power transmission systems to transfer power between pulleys.

- Flat belts: Used in various industries for conveying or power transmission.

- Specialty belts: Custom-made belts designed for specific applications, such as heat-resistant or anti-static belts.

4. How do you ensure that the belt cutter machine is set up correctly for a specific cutting job?

To ensure proper setup for a specific cutting job, I follow these steps:

- Read machine specifications: Determine the machine’s capabilities and limitations.

- Inspect the belt: Check the belt type, size, and thickness to ensure compatibility.

- Set blade parameters: Adjust the blade height, angle, and pressure based on the belt material and thickness.

- Calibrate machine: Perform a test cut on a scrap piece of belt to verify accuracy.

- Adjust tension: Set the belt tension according to the manufacturer’s recommendations.

5. Explain how you troubleshoot and resolve a situation where the belt cutter machine is not cutting cleanly.

To troubleshoot and resolve unclean cuts, I follow a systematic approach:

- Inspect the blade: Check for dullness, damage, or misalignment.

- Verify belt tension: Ensure that the belt is properly tensioned.

- Examine cutting surface: Check for any debris or unevenness that may hinder the cutting process.

- Adjust machine parameters: Fine-tune blade settings, such as height, angle, and pressure.

- Test and calibrate: Perform test cuts and adjust settings until the desired cut quality is achieved.

6. How do you maintain a safe working environment when operating a belt cutter machine?

- Wear appropriate safety gear: Safety glasses, gloves, and hearing protection.

- Keep work area clean and organized: Remove any potential tripping hazards or obstacles.

- Inspect machine before use: Check for any damage or loose parts.

- Follow operating instructions carefully: Adhere to the manufacturer’s guidelines.

- Never reach into the cutting zone: Keep hands and fingers away from the blade.

7. Describe the process of replacing a worn blade on a belt cutter machine.

To replace a worn blade safely and efficiently, I follow these steps:

- Disconnect power source: Ensure the machine is not energized.

- Unclamp the blade holder: Loosen the bolts or screws that secure the blade in place.

- Remove the worn blade: Carefully remove the old blade from the holder.

- Insert the new blade: Align the new blade correctly and insert it into the holder.

- Tighten the blade holder: Secure the blade by tightening the bolts or screws.

- Recalibrate the machine: Perform test cuts and adjust settings to ensure proper blade alignment and cutting accuracy.

8. Explain the importance of proper blade selection for a belt cutter machine.

- Material compatibility: Choose a blade material that is suitable for the type of belt being cut.

- Blade sharpness: A sharp blade ensures clean and precise cuts, reducing the risk of belt damage.

- Blade shape and geometry: Select a blade shape and geometry that is appropriate for the specific cutting application.

- Blade life: Consider the blade’s durability and lifespan to minimize downtime due to blade changes.

- Cost-effectiveness: Choose a blade that provides a balance between performance and cost.

9. How do you ensure that the cut belts meet the required specifications?

- Verify cutting parameters: Confirm that the machine settings, such as blade height and pressure, are correct.

- Inspect cut belts: Visually examine the belts to ensure they meet the desired length, width, and shape.

- Use measuring tools: Utilize measuring tapes or calipers to accurately measure the belt dimensions.

- Calibrate machine regularly: Conduct periodic calibration of the machine to maintain cutting accuracy.

- Follow quality control procedures: Adhere to established quality control measures to ensure consistent belt quality.

10. Explain how you optimize the cutting process to maximize productivity and minimize waste.

- Optimize blade selection: Choose the most appropriate blade for the cutting task to ensure clean and efficient cuts.

- Calibrate the machine precisely: Ensure that the machine settings are optimized for the material being cut.

- Minimize blade changes: Select a durable blade that can handle extended cutting sessions, reducing downtime for blade changes.

- Use sharp blades: Sharp blades cut cleanly, reducing the risk of belt damage and material waste.

- Proper belt handling: Handle belts carefully to prevent damage and ensure accurate cutting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Belt Cutters are responsible for cutting and preparing belts for use in production and maintenance. They inspect and cut belts to specified dimensions, ensure proper tension and alignment, and maintain and repair belt conveyors and other equipment. Key responsibilities may include:

1. Belt Inspection and Measurement

Inspect belts for damage, wear, and defects using tools like calipers and gauges.

- Measure belts to determine their length, width, and thickness.

- Calculate the necessary amount of material to cut based on specified dimensions.

2. Belt Cutting and Preparation

Cut belts to the required length and shape using specialized cutting tools.

- Prepare belts for use by splicing or joining them together using adhesives, fasteners, or welding techniques.

- Ensure the cut belts meet the required specifications and tolerances.

3. Belt Installation and Maintenance

Install belts onto conveyors and other equipment according to specified procedures.

- Adjust and tension belts to ensure proper operation and prevent slippage or damage.

- Maintain belts by cleaning, lubricating, and inspecting them regularly.

- Replace belts as needed to ensure continuous and efficient production.

4. Equipment Maintenance and Repair

Perform routine maintenance and repairs on belt conveyors and other equipment:

- Inspect and lubricate components like bearings, pulleys, and motors.

- Troubleshoot and resolve mechanical issues to minimize downtime.

- Follow proper safety protocols and adhere to established maintenance schedules.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help candidates ace the interview for a Belt Cutter position:

1. Research the Company and Role

Research the company’s background, industry, and specific needs related to belt cutting.

- Review the job description thoroughly to understand the key responsibilities and qualifications required.

- Identify any specialized equipment or techniques that may be relevant to the role.

2. Highlight Relevant Skills and Experience

Emphasize your skills in belt inspection, cutting, and preparation, as well as your knowledge of belt conveyors and other equipment.

- Quantify your accomplishments and provide specific examples of how you have contributed to the success of previous projects.

- Discuss your experience in maintaining and repairing equipment, including any certifications or training you have received.

3. Demonstrate Safety Awareness

Highlight your understanding of safety protocols and procedures related to belt cutting and equipment maintenance.

- Explain how you ensure your own safety and the safety of others when working with belts and equipment.

- Describe your experience in following established lockout/tagout procedures and adhering to safety regulations.

4. Be Prepared for Technical Questions

Practice answering technical questions related to belt cutting and conveyor maintenance, such as:

- How do you determine the correct tension for a belt?

- What are the different methods of splicing belts?

- How do you troubleshoot a belt that is slipping or tracking off center?

5. Prepare Thoughtful Questions

Asking insightful questions at the end of the interview demonstrates your interest and enthusiasm for the role.

- Inquire about the company’s growth plans and how the Belt Cutter position contributes to those goals.

- Ask about opportunities for professional development and advancement within the organization.

- Express your commitment to safety and continuous improvement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Belt Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!