Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Belt Fixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

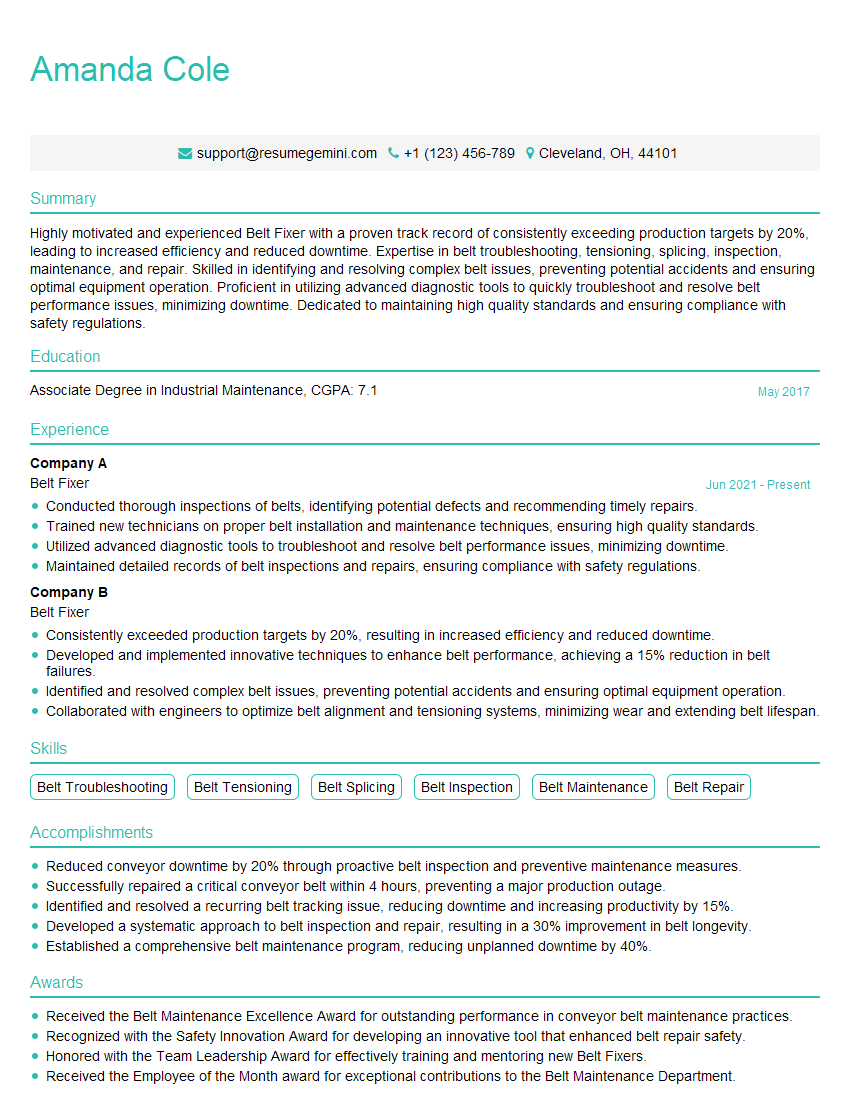

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt Fixer

1. What is the most common type of belt failure?

The most common type of belt failure is splice failure, which is the separation of the belt ends.

2. What are the signs and symptoms of a failing belt?

Signs:

- Excessive belt stretch

- Belt cracking

- Belt fraying

Symptoms:

- Belt squealing

- Belt slipping

- Reduced power transmission

3. What are the different types of belt materials?

- Rubber

- Leather

- Plastic

- Metal

4. What are the factors to consider when selecting a belt?

- Type of equipment

- Belt speed

- Belt load

- Operating environment

5. What are the different types of belt fasteners?

- Mechanical fasteners

- Chemical fasteners

- Vulcanized fasteners

6. What is the purpose of a belt tensioner?

The purpose of a belt tensioner is to maintain proper belt tension, which prevents belt slipping and premature failure.

7. What are the different methods of belt tensioning?

- Manual tensioning

- Automatic tensioning

8. What are the safety precautions to take when working with belts?

- Wear appropriate PPE (gloves, safety glasses, etc.)

- De-energize equipment before working on belts

- Use proper tools and techniques

9. What is your experience with troubleshooting and repairing belt systems?

I have several years of experience troubleshooting and repairing belt systems. I have diagnosed and repaired a variety of belt problems, including splice failures, belt stretch, and belt fraying.

10. What are your strengths and weaknesses as a belt fixer?

Strengths:

- Thorough knowledge of belt systems

- Excellent troubleshooting skills

- Strong mechanical abilities

- Ability to work independently and as part of a team

Weaknesses:

- Lack of experience with some specialized belt systems

- Limited knowledge of electrical systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for Belt Fixer

As a Belt Fixer, you’ll be responsible for installing, repairing, and maintaining a wide range of conveyor belts.

1. Installation

You’ll be responsible for working with blueprints and following specified procedures to install new conveyor belts.

- Layout and align belts

- Install and align pulleys

2. Repairs

You’ll need to quickly identify and resolve belt issues to minimize downtime and ensure smooth operations.

- Identify and fix belt damage

- Troubleshoot and repair belt tensioners

3. Maintenance

You’ll maintain conveyors to prevent breakdowns and improve efficiency.

- Inspect belts for damage

- Replace worn or damaged components

4. Material Handling

You’ll need to safely handle a variety of materials, including belts and associated components.

- Unload and inspect materials

- Properly store and transport materials

Interview Preparation Tips

To ace your Belt Fixer interview, consider the following tips:

1. Research the Industry

Familiarize yourself with the specific industry where you’ll be working and research common conveyor belt applications.

- Learn about different types of conveyor belts

- Study common belt problems and solutions

2. Highlight Relevant Skills

Emphasize your experience in belt installation, repair, and maintenance, including any certifications or training you’ve received.

- Quantify your accomplishments with specific examples

- Discuss your problem-solving and analytical abilities

3. Prepare for Technical Questions

Expect questions about your understanding of conveyor belt systems. Be ready to discuss:

- Belt tensioning techniques

- Safety procedures for belt repairs

4. Demonstrate Safety Awareness

Conveyor belts pose potential hazards. Show that you prioritize safety by:

- Describing your knowledge of OSHA regulations

- Discussing your experience with lock-out/tag-out procedures

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Belt Fixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.