Are you gearing up for an interview for a Belt Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Belt Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

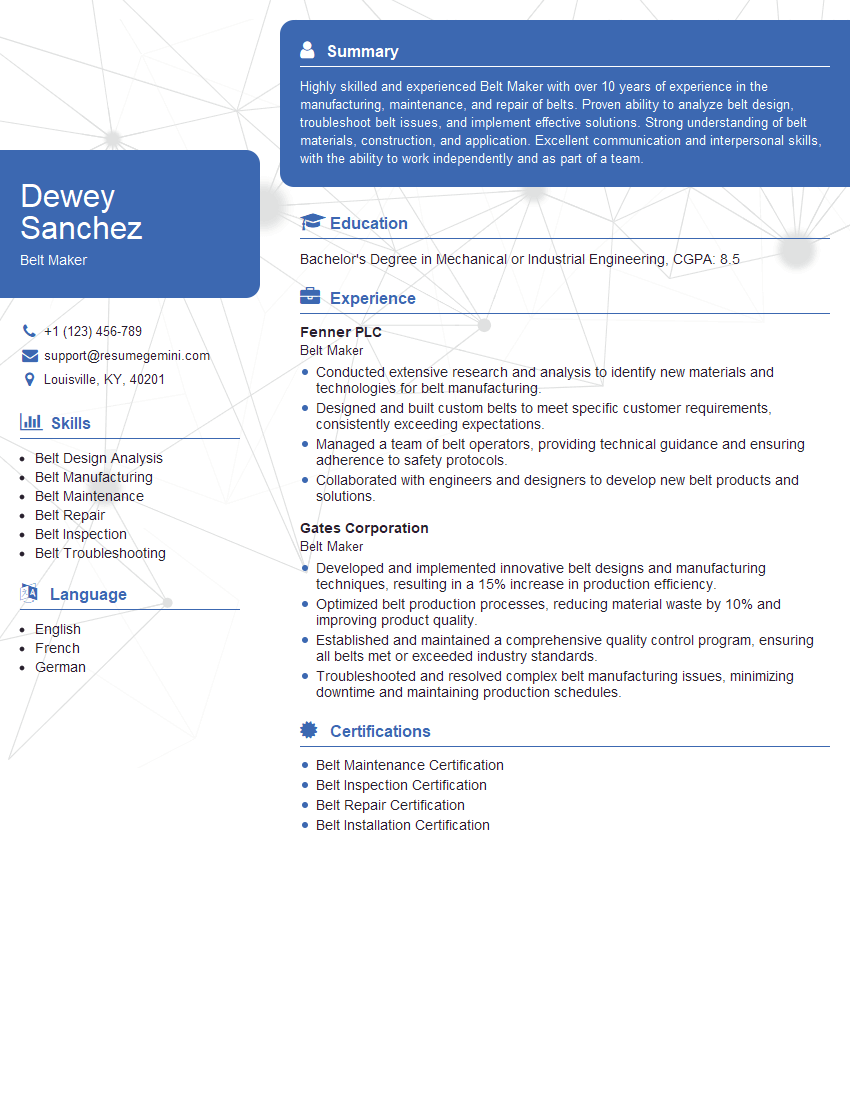

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt Maker

1. What are the different types of leather used in belt making and which is the best for durability?

Different types of leather used:

- Full-grain leather: The most durable and expensive, made from the top layer of the hide

- Top-grain leather: Made from the second layer of the hide, less durable than full-grain but still a high-quality option

- Genuine leather: Made from the remaining layers of the hide, less durable than full-grain and top-grain but still suitable for some applications

- Bonded leather: Made from leftover leather scraps, the least durable type but the most affordable

Full-grain leather is the best for durability as it is the strongest and most resistant to wear and tear.

2. What are the different types of belt buckles and how do you choose the right one?

- Tongue buckles: The most common type of belt buckle, consisting of a tongue that slides into a frame

- Roller buckles: Similar to tongue buckles but with a roller that allows the belt to be tightened or loosened more easily

- Auto-lock buckles: Buckles that automatically lock when the belt is fastened, providing a secure fit

- Snap buckles: Buckles that snap together, making them easy to remove and put on

- Hook buckles: Buckles that hook onto a loop on the belt, providing a secure fit but not as easy to adjust as other types

Choosing the right buckle:

Consider the style of the belt, the material it is made from, and the intended use. For example, a dress belt might have a tongue or roller buckle, while a work belt might have an auto-lock or snap buckle.

3. What are the different methods of attaching a belt loop to a belt?

- Sewing: The most common method, involves stitching the belt loop to the belt using a sewing machine

- Riveting: Using rivets to attach the belt loop to the belt, providing a strong and durable connection

- Chicago screws: Using Chicago screws to attach the belt loop to the belt, allowing for easy removal if needed

- Welding: Welding the belt loop to the belt, providing a permanent and very strong connection

Choosing the best method:

Consider the material of the belt and belt loop, as well as the intended use of the belt. For example, sewing might be suitable for a casual belt, while riveting or welding might be better for a more durable belt.

4. How do you measure and cut leather accurately for belt making?

- Measure the length of the belt using a tape measure or ruler

- Add a few inches to the length to allow for the buckle and any other hardware

- Mark the length on the leather using a pencil or chalk

- Use a sharp knife or leather cutter to cut the leather along the marked line

- Smooth the edges of the leather using a sanding block or edge slicker

Tips:

Use a sharp knife or leather cutter to ensure a clean cut. Be careful not to cut yourself. Use a straightedge or ruler to guide your cut for accuracy. Measure twice, cut once to avoid mistakes.

5. What are the different techniques for burnishing the edges of a belt?

- Wax burnishing: Using a piece of beeswax or a burnishing agent to rub the edges of the leather, creating a smooth and polished finish

- Gum tragacanth burnishing: Using a solution of gum tragacanth and water to rub the edges of the leather, creating a hard and durable finish

- Machine burnishing: Using a machine to burnish the edges of the leather, providing a consistent and repeatable finish

Choosing the best technique:

Consider the type of leather and the desired finish. For example, wax burnishing is suitable for a soft and supple leather, while gum tragacanth burnishing is better for a harder and more durable leather.

6. How do you attach a buckle to a belt?

- Mark the location of the buckle on the belt

- Cut a slot in the belt using a sharp knife or leather cutter

- Insert the buckle into the slot

- Secure the buckle using rivets, screws, or other hardware

Tips:

Make sure the buckle is centered on the belt. Use a sharp knife or leather cutter to ensure a clean cut. Be careful not to cut yourself. Use sturdy hardware to secure the buckle.

7. What are the different types of stitches used in belt making and when do you use them?

- Saddle stitch: A strong and durable stitch that is commonly used in belt making

- Hand stitch: A more decorative stitch that is often used on the edges of belts

- Machine stitch: A fast and efficient stitch that is often used for mass-produced belts

Choosing the best stitch:

Consider the type of leather, the strength required, and the desired aesthetic. For example, a saddle stitch is a good choice for a durable belt made from thick leather, while a hand stitch might be better for a more decorative belt.

8. How do you care for and maintain a leather belt?

- Keep the belt clean by wiping it down with a damp cloth

- Condition the belt regularly using a leather conditioner to keep it soft and supple

- Store the belt in a cool and dry place when not in use

- Avoid exposing the belt to direct sunlight or heat

- If the belt gets wet, dry it immediately with a soft cloth

9. What are the current trends in belt making?

- Use of exotic leathers, such as alligator, ostrich, and snake

- Incorporation of decorative hardware, such as studs, buckles, and chains

- Use of bright and bold colors

- Custom-made belts

10. What are the challenges of belt making?

- Working with different types of leather, each with its own unique properties

- Achieving precise and consistent cuts and stitches

- Creating belts that are both durable and stylish

- Keeping up with current trends while also maintaining a unique style

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Belt Makers are responsible for the production of belts, which are used in a variety of applications, including clothing, industrial machinery, and automotive parts. They must be skilled in the use of various tools and equipment, and have a strong understanding of the materials and processes involved in belt making.

1. Material Selection and Preparation

Belt Makers must have a strong understanding of the different types of materials used in belt making, and be able to select the appropriate material for the specific application. They must also be able to prepare the material properly, by cutting it to the correct size and shape, and applying any necessary treatments or coatings.

- Select and prepare materials such as leather, rubber, or fabric

- Cut materials to the desired length and shape

- Apply adhesives or other treatments to prepare materials for assembly

2. Assembly and Construction

Belt Makers must be able to assemble and construct belts according to the specified design. They must be able to use a variety of tools and equipment, and must be able to work accurately and efficiently. They must also be able to inspect belts for quality and ensure that they meet the customer’s requirements.

- Assemble belts using adhesives, rivets, or other fasteners

- Inspect belts for defects and ensure they meet specifications

- Repair or replace damaged belts

3. Equipment Maintenance

Belt Makers must be able to maintain their equipment in good working order. They must be able to identify and troubleshoot problems, and must be able to perform basic maintenance tasks. They must also be able to follow safety procedures and work in a safe manner.

- Maintain and repair equipment used in belt making

- Troubleshoot and resolve equipment problems

- Follow safety procedures and maintain a clean and organized work area

4. Quality Control

Belt Makers must be able to ensure that the belts they produce meet the customer’s requirements. They must be able to inspect belts for defects, and must be able to identify and correct any problems. They must also be able to maintain records of their work, and must be able to provide documentation to customers.

- Inspect belts for defects and ensure they meet specifications

- Identify and correct problems with belts

- Maintain records of work performed and provide documentation to customers

Interview Tips

Preparing for a job interview can be daunting, but there are a few things you can do to increase your chances of success. Here are some tips:

1. Research the Company and the Position

Before you go to an interview, it is important to do your research. Learn as much as you can about the company and the position you are applying for. This will show the interviewer that you are interested in the job and that you have taken the time to learn about the company’s culture and values.

- Visit the company’s website and social media pages

- Read articles and news about the company

- Talk to people who work at the company, if possible

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked. It is a good idea to practice your answers to these questions in advance. This will help you to feel more confident and prepared during the interview.

- Tell me about yourself

- Why are you interested in this job?

- What are your strengths and weaknesses?

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time. This will show the interviewer that you are respectful of their time and that you are serious about the job.

- Wear a suit or business casual attire

- Be on time for your interview

- Make eye contact and smile when you meet the interviewer

4. Be Yourself and Be Enthusiastic

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be enthusiastic and positive, and let the interviewer see your passion for the job.

- Be genuine and authentic

- Show your enthusiasm for the job

- Be positive and upbeat

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Belt Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!