Are you gearing up for an interview for a Belt Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Belt Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

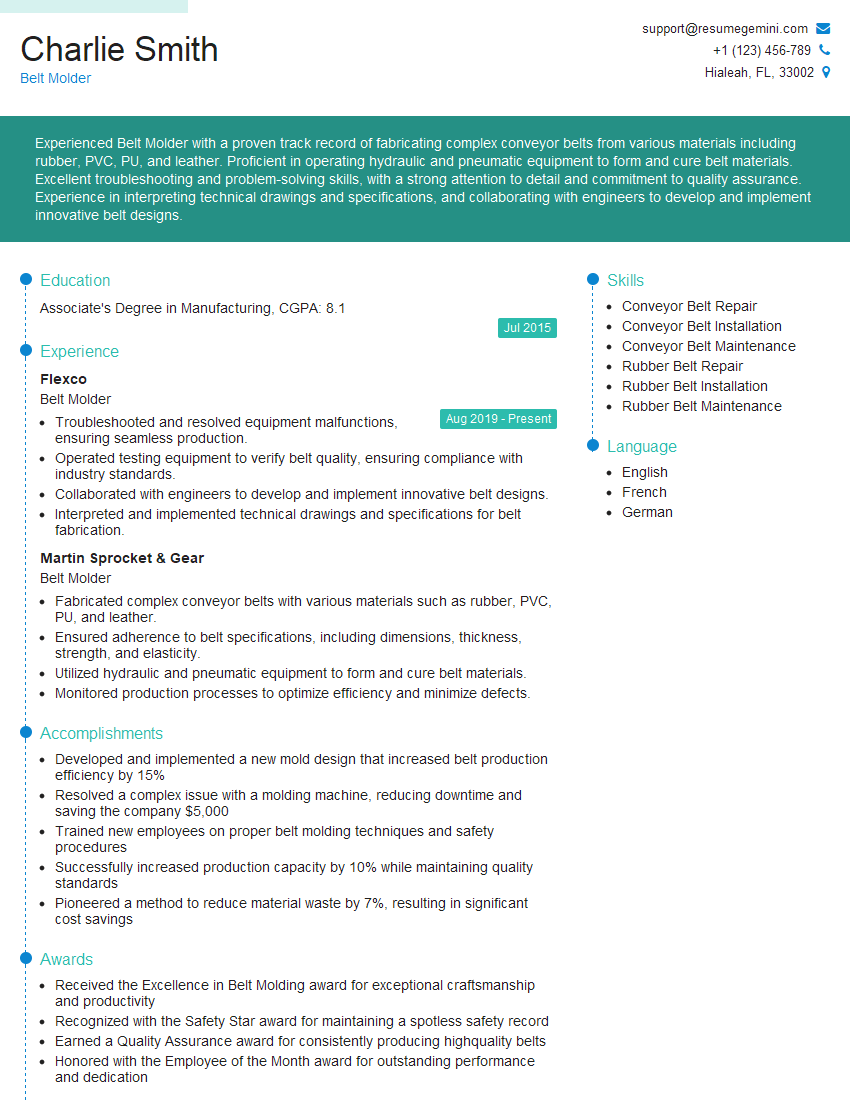

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt Molder

1. What are the key factors to consider when designing a belt mold for a specific product?

Sample Answer:

- Product specifications: Dimensions, shape, geometry, tolerances

- Material properties: Rheology, flow behavior, shrinkage, reinforcement

- Production requirements: Production rate, cycle time, part quality

- Mold design constraints: Material compatibility, cooling, ejection

- Industry standards and best practices: Design guidelines, safety considerations

2. Explain the different types of belt molds and their advantages and disadvantages.

Sample Answer:

Types of Belt Molds:

- Continuous Molds: High production rates, continuous operation

- Intermittent Molds: Lower production rates, increased flexibility

- Index Molds: Variable cycle times, allows for complex part designs

Advantages and Disadvantages:

- Continuous: High cost, limited design options

- Intermittent: Lower productivity, more labor-intensive

- Index: Increased complexity, higher maintenance

3. What are the steps involved in the design process for a belt mold?

Sample Answer:

- Problem definition and requirements gathering

- Concept development and evaluation

- Mold design and analysis (CAD/CAE)

- Mold fabrication and assembly

- Mold testing and validation

4. Describe the importance of flow simulation in belt mold design.

Sample Answer:

- Optimized material flow: Minimizing defects, improving product quality

- Reduced cycle times: Identifying flow bottlenecks, reducing cooling time

- Increased mold life: Predicting wear patterns, preventing premature failure

- Virtual mold testing: Validating design before physical prototyping

5. How do you ensure that a belt mold meets the required quality standards?

Sample Answer:

- Materials and fabrication compliance: Verifying materials and workmanship

- Dimensional inspection: Meeting product specifications and tolerances

- Part testing: Evaluating product performance, durability, and consistency

- Process monitoring and control: Maintaining stable process parameters

- Continuous improvement: Identifying and implementing quality enhancements

6. What is your experience in troubleshooting and repair of belt molds?

Sample Answer:

- Mold failure analysis: Identifying root cause of malfunctions

- Mold repair and refurbishment: Restoring mold to optimal condition

- Preventive maintenance: Scheduling regular inspections, identifying potential issues

- Equipment upgrades and modifications: Enhancing mold performance and reliability

7. How do you stay up-to-date with the latest advancements in belt mold technology?

Sample Answer:

- Industry conferences and trade shows: Attending events to learn about new products and innovations

- Technical publications and journals: Reading articles and research papers

- Online resources and webinars: Accessing up-to-date information from industry experts

- Collaboration with vendors and partners: Sharing knowledge and best practices

8. What are the key metrics for measuring the performance of a belt mold?

Sample Answer:

- Production rate: Number of parts produced per hour

- Cycle time: Time from mold loading to part ejection

- Part quality: Meeting product specifications and customer requirements

- Mold life: Number of cycles before major repairs or replacement

- Maintenance costs: Expenses associated with mold upkeep and repairs

9. What are the safety considerations when operating and maintaining belt molds?

Sample Answer:

- Proper PPE usage: Wearing appropriate protective gear, including gloves, safety glasses, and hearing protection

- Mold handling and transportation: Using proper equipment and techniques to avoid injury

- Mold inspection and maintenance: Regular checks to identify potential hazards and prevent accidents

- Emergency procedures: Establishing clear protocols for emergencies, such as mold failures or spills

10. How do you work effectively as part of a team in a mold design and manufacturing environment?

Sample Answer:

- Communication and collaboration: Open and frequent communication with team members

- Knowledge sharing: Contributing expertise and learning from others

- Problem-solving: Working together to identify and resolve technical challenges

- Responsibility and accountability: Taking ownership of tasks and meeting deadlines

- Continuous improvement: Actively seeking feedback and implementing improvements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Belt Molders are responsible for overseeing the production of molded rubber or plastic products. They operate and maintain molding machines, ensuring that they are functioning properly and producing high-quality products.

1. Machine Operation

Operate and maintain molding machines to produce rubber or plastic products.

- Set up and adjust machines according to specifications.

- Monitor machines during operation to ensure proper functioning.

2. Mold Preparation

Prepare molds for use in the molding process.

- Clean and inspect molds for defects.

- Apply release agents to molds to prevent sticking.

3. Material Handling

Handle and prepare materials used in the molding process.

- Load and unload materials into and from molding machines.

- Mix and prepare materials according to specified proportions.

4. Quality Control

Inspect finished products to ensure they meet quality standards.

- Check products for defects, such as cracks, voids, or discoloration.

- Make adjustments to molding machines or processes as needed to improve product quality.

Interview Tips

Preparing for an interview for a Belt Molder position requires a combination of technical knowledge and an understanding of the industry and company you are applying to. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and culture. Research the specific role you are applying for and identify the key responsibilities and qualifications.

- Visit the company website and social media pages.

- Read industry news and articles to stay up-to-date on trends.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you articulate your skills and experience clearly and confidently.

- Use the STAR method (Situation, Task, Action, Result) to answer questions about your past experiences.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

3. Highlight Your Technical Skills

Emphasize your technical skills in molding, machine operation, and quality control. Provide specific examples of your experience and how you have used these skills to improve production efficiency and product quality.

- Describe your experience in operating different types of molding machines.

- Share examples of how you have implemented process improvements to enhance product quality.

4. Be Prepared to Discuss Safety

Belt Molders are responsible for maintaining a safe work environment. Be prepared to discuss your knowledge of safety procedures and your commitment to following them.

- Explain your understanding of workplace safety regulations and best practices.

- Provide examples of how you have ensured safety in your previous roles.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare a few questions that demonstrate your enthusiasm and eagerness to learn more.

- Ask about the company’s growth plans and future projects.

- Inquire about opportunities for professional development and advancement.

Next Step:

Now that you’re armed with the knowledge of Belt Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Belt Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini