Feeling lost in a sea of interview questions? Landed that dream interview for Belt Polisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Belt Polisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

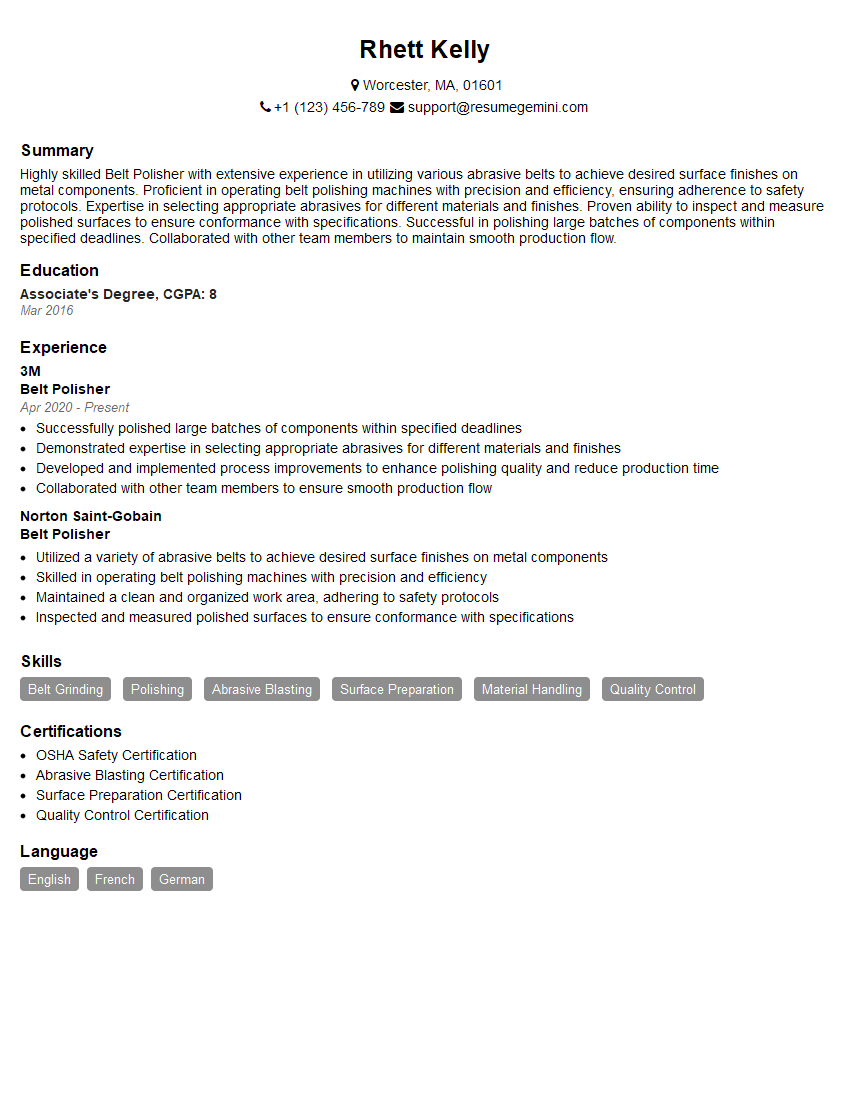

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt Polisher

1. Explain the different types of abrasive belts used in belt polishing and their applications?

There are different types of abrasive belts used in belt polishing, each with its own specific applications. Here are some of the most common types:

- Ceramic belts: Ceramic belts are made from a blend of ceramic and aluminum oxide, and they are known for their durability and long lifespan. They are often used for heavy-duty applications, such as grinding and shaping metal.

- Aluminum oxide belts: Aluminum oxide belts are made from a mineral called corundum, and they are known for their sharpness and cutting ability. They are often used for light-duty applications, such as sanding wood and plastic.

- Zirconia belts: Zirconia belts are made from a mineral called zirconium oxide, and they are known for their strength and durability. They are often used for medium-duty applications, such as grinding and finishing metal.

- Tri-Rex belts: Tri-Rex belts are made from a blend of ceramic, aluminum oxide, and zirconia. They are known for their versatility and long lifespan, and they can be used for a wide range of applications.

2. What are the factors that affect the surface finish of a polished surface?

Grit size

- The grit size of the abrasive belt is one of the most important factors that affects the surface finish of a polished surface. A finer grit size will produce a smoother surface finish, while a coarser grit size will produce a rougher surface finish.

Belt speed

- The speed of the abrasive belt is another important factor that affects the surface finish of a polished surface. A faster belt speed will produce a smoother surface finish, while a slower belt speed will produce a rougher surface finish.

Pressure

- The pressure that is applied to the abrasive belt is also a factor that affects the surface finish of a polished surface. More pressure will produce a smoother surface finish, while less pressure will produce a rougher surface finish.

Lubrication

- Lubrication can help to improve the surface finish of a polished surface. Lubrication can help to reduce friction and heat, which can lead to a smoother surface finish.

3. What are the different types of belt polishing machines?

There are three main types of belt polishing machines that are commonly used in industry:

- Horizontal belt polishing machines: Horizontal belt polishing machines are the most common type of belt polishing machine. They are typically used for polishing flat surfaces.

- Vertical belt polishing machines: Vertical belt polishing machines are used for polishing cylindrical surfaces. They are also known as centerless belt polishing machines.

- Wide belt polishing machines: Wide belt polishing machines are used for polishing large, flat surfaces. They are typically used in the automotive and aerospace industries.

4. What are the safety precautions that must be taken when operating a belt polishing machine?

There are a number of safety precautions that must be taken when operating a belt polishing machine. These precautions include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and a dust mask.

- Ensuring that the machine is properly grounded.

- Keeping the work area clean and free of debris.

- Never operating the machine with the guards removed.

- Being aware of the potential hazards of the machine, such as the rotating belt and the sparks that can be generated.

5. What are the maintenance procedures that are required for a belt polishing machine?

There are a number of maintenance procedures that are required for a belt polishing machine. These procedures include:

- Regularly cleaning the machine and removing any debris.

- Inspecting the belt for damage and replacing it if necessary.

- Lubricating the machine according to the manufacturer’s instructions.

- Tightening the belt if it becomes loose.

- Checking the electrical connections and making sure that they are secure.

6. What are the common problems that can occur with a belt polishing machine?

There are a number of common problems that can occur with a belt polishing machine. These problems include:

- The belt can become loose: If the belt becomes loose, it can slip off the pulleys and cause damage to the machine.

- The belt can become damaged: The belt can become damaged if it is used with the wrong grit size, if it is operated at the wrong speed, or if it is not properly lubricated.

- The machine can overheat: The machine can overheat if it is used for too long or if it is not properly ventilated.

- The electrical connections can become loose: The electrical connections can become loose if the machine is not properly maintained.

7. How do you troubleshoot a belt polishing machine?

If a belt polishing machine is not working properly, there are a few steps that can be taken to troubleshoot the problem:

- Check the power supply: Make sure that the machine is plugged into a power outlet and that the power switch is turned on.

- Check the belt: Make sure that the belt is properly installed and that it is not damaged.

- Check the pulleys: Make sure that the pulleys are properly aligned and that they are not damaged.

- Check the electrical connections: Make sure that all of the electrical connections are secure.

- Check the lubrication: Make sure that the machine is properly lubricated.

- Check the bearings: Make sure that the bearings are not damaged or worn out.

8. How do you adjust the speed of a belt polishing machine?

The speed of a belt polishing machine can be adjusted by changing the size of the pulleys on the machine. A larger pulley will result in a slower belt speed, while a smaller pulley will result in a faster belt speed.

9. How do you change the belt on a belt polishing machine?

To change the belt on a belt polishing machine, follow these steps:

- Turn off the machine and unplug it from the power outlet.

- Remove the guards from the machine.

- Loosen the tension on the belt.

- Remove the old belt from the machine.

- Install the new belt on the machine.

- Tighten the tension on the belt.

- Replace the guards on the machine.

- Plug the machine back into the power outlet and turn it on.

10. How do you maintain a belt polishing machine?

To maintain a belt polishing machine, follow these steps:

- Clean the machine regularly.

- Inspect the belt for damage.

- Lubricate the machine according to the manufacturer’s instructions.

- Tighten the belt if it becomes loose.

- Check the electrical connections and make sure that they are secure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Belt Polishers are responsible for the operation and maintenance of belt polishing machines. The primary function of these machines is to smooth and finish metal surfaces using abrasive belts. Belt Polishers work in various industries, including manufacturing and metal fabrication.

1. Operating Belt Polishing Machines

Belt Polishers are responsible for setting up and operating belt polishing machines. They must be able to select the appropriate abrasive belt for the job and adjust the machine to the correct speed and pressure. They must also be able to monitor the machine’s operation and make adjustments as needed.

- Set up and adjust belt polishing machines according to specifications.

- Load and unload workpieces from the machine.

- Monitor the machine’s operation and make adjustments as needed.

- Identify and correct any problems with the machine.

2. Maintaining Belt Polishing Machines

Belt Polishers are responsible for maintaining their machines in good working condition. They must be able to perform regular maintenance tasks, such as cleaning, lubricating, and adjusting the machine. They must also be able to identify and repair any problems with the machine.

- Clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine for any damage or wear and tear.

- Repair any problems with the machine, such as replacing worn belts or bearings.

- Keep a maintenance log to track the machine’s performance.

3. Quality Control

Belt Polishers are responsible for ensuring that the workpieces they produce meet the required quality standards. They must be able to inspect the workpieces for defects, such as scratches, dents, or burrs. They must also be able to make adjustments to the machine or the process to correct any defects.

- Inspect workpieces for defects.

- Make adjustments to the machine or the process to correct any defects.

- Maintain records of the quality of the workpieces produced.

- Work with other departments to identify and resolve quality issues.

4. Safety

Belt Polishing is a potentially hazardous occupation. Belt Polishers must be aware of the risks associated with their work and take precautions to avoid injury. They must wear appropriate safety gear, such as gloves, safety glasses, and earplugs. They must also be trained on the safe operation of the belt polishing machine.

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Be trained on the safe operation of the belt polishing machine.

- Follow all safety procedures.

- Report any unsafe conditions or practices to their supervisor.

Interview Tips

Preparing for a job interview can be stressful, but there are some things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work at the company.

- Review the job description carefully.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Write down your answers to common interview questions.

- Practice saying your answers out loud.

- Ask a friend or family member to help you practice.

- Use the STAR method to answer behavioral questions.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the company culture. You should also make sure your shoes are clean and polished.

- Choose clothes that are clean, pressed, and appropriate for the company culture.

- Make sure your shoes are clean and polished.

- Avoid wearing too much jewelry or perfume.

- Pay attention to your grooming.

4. Be on time

Punctuality is important in any interview. Make sure you arrive at the interview on time, or even a few minutes early. This shows the interviewer that you are respectful of their time.

- Plan your route to the interview in advance.

- Leave early to give yourself plenty of time.

- If you are running late, call the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Belt Polisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!