Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Belt-Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Belt-Press Operator so you can tailor your answers to impress potential employers.

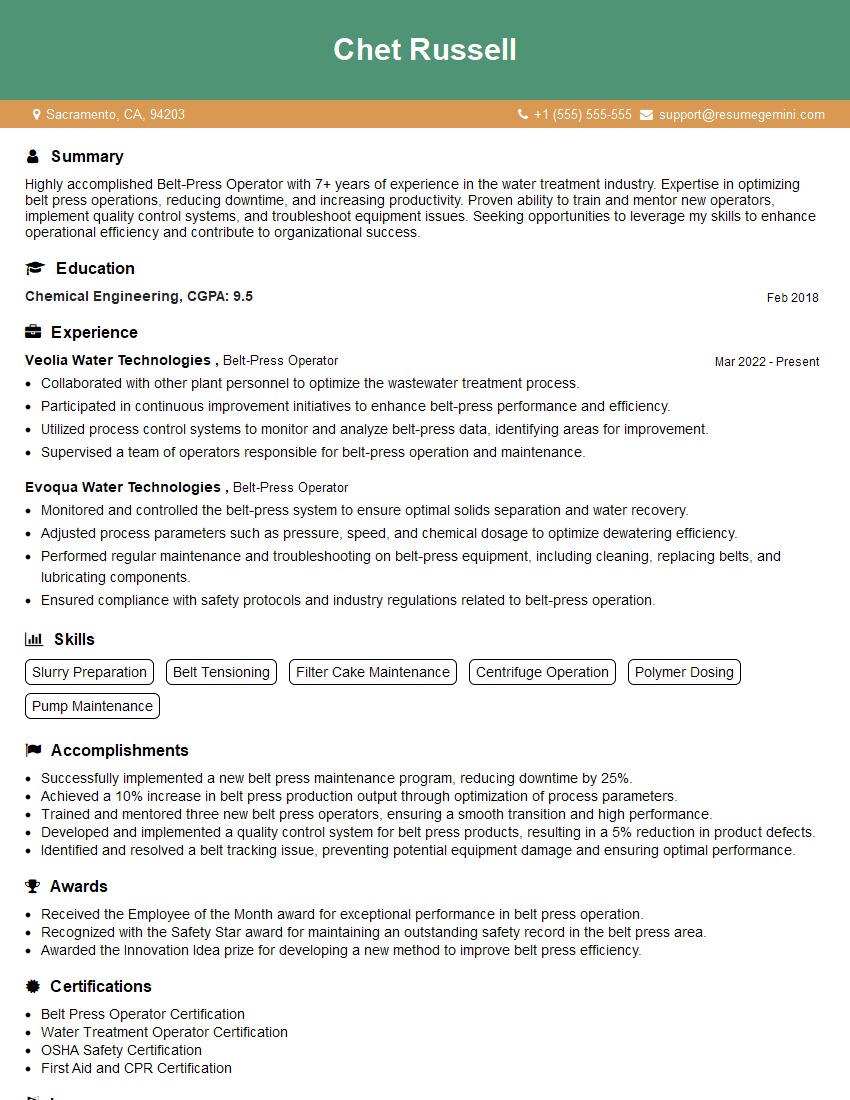

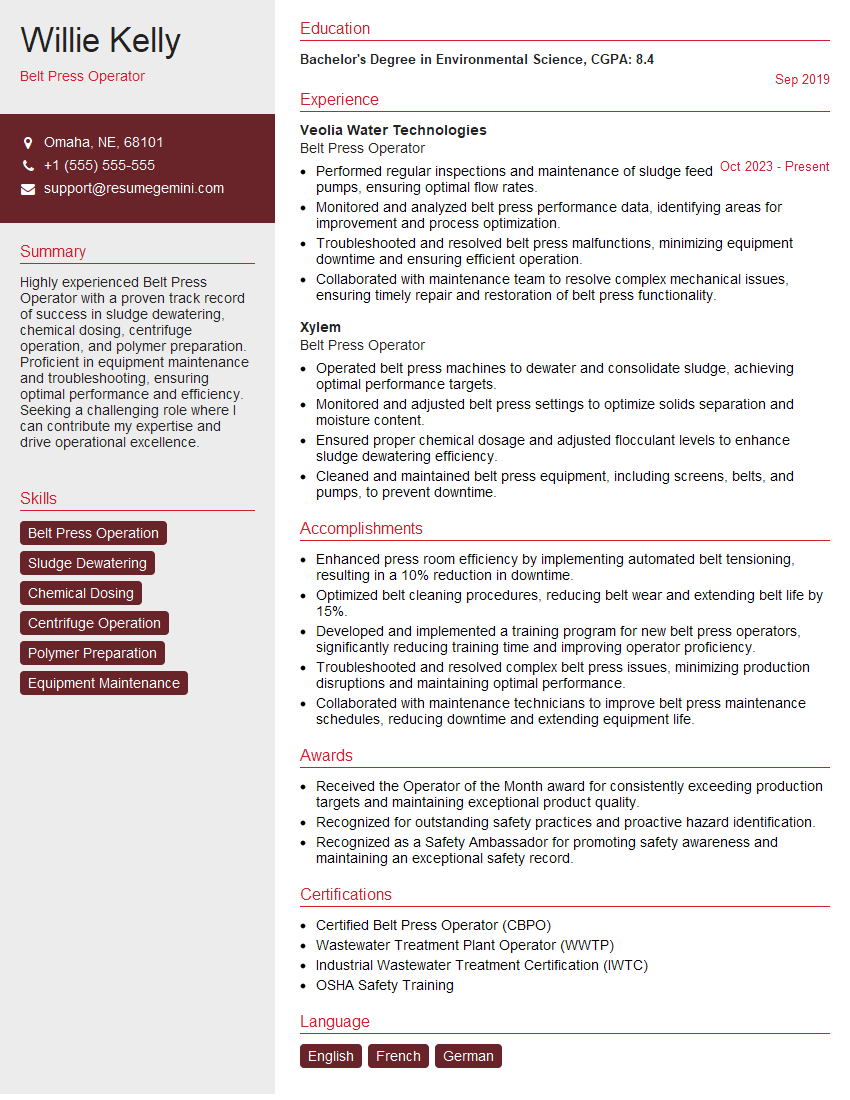

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt-Press Operator

1. Describe the key responsibilities of a Belt-Press Operator?

- Operate belt press equipment to dewater sludge and other materials.

- Monitor and adjust process parameters to ensure optimal performance.

- Maintain and troubleshoot equipment to minimize downtime.

- Ensure compliance with safety and environmental regulations.

- Work effectively as part of a team.

2. What are the different types of belt presses used in industrial settings?

Gravity belt presses

- Utilize gravity to dewater sludge.

- Suitable for low-viscosity sludge.

Vacuum belt presses

- Employ vacuum suction to enhance dewatering.

- Handle higher-viscosity sludge.

Pressure belt presses

- Apply external pressure to further dewater sludge.

- Produce dryer cake.

3. Explain the factors that influence the performance of a belt press?

- Sludge characteristics (viscosity, solids content)

- Belt speed and tension

- Pressure applied to the sludge

- Flocculant dosage

- Equipment condition

4. Describe the common maintenance procedures for a belt press?

- Regular cleaning and inspection of belts and rollers

- Replacement of worn or damaged components

- Lubrication of moving parts

- Calibration of sensors and controls

- Troubleshooting and repair of equipment malfunctions

5. What are the safety precautions to be taken while operating a belt press?

- Wear appropriate personal protective equipment (PPE)

- Follow lockout/tagout procedures

- Be aware of pinch points and moving parts

- Handle chemicals and flocculants safely

- Report any unsafe conditions or equipment malfunctions immediately

6. How do you troubleshoot common problems encountered with belt presses?

Describe troubleshooting steps for specific problems, such as:

- Low cake solids

- High moisture content in the filtrate

- Belt tracking issues

- Equipment leaks

7. How can you optimize the performance of a belt press to maximize dewatering efficiency?

- Fine-tune process parameters (belt speed, pressure, flocculant dosage)

- Monitor sludge characteristics and adjust parameters accordingly

- Implement regular maintenance and preventative maintenance

- Use high-quality consumables (belts, flocculants)

8. What experience do you have with different types of sludge dewatering equipment?

Describe previous experience with belt presses, centrifuges, or other dewatering technologies.

9. How do you stay updated on the latest advancements in belt press technology?

- Attend industry conferences and webinars

- Read technical journals and articles

- Network with other professionals in the field

- Consult with equipment manufacturers and suppliers

10. Why are you interested in working as a Belt-Press Operator for our company?

Express interest in the company’s mission, values, or specific projects related to belt press operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt-Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt-Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Belt-Press Operators play a crucial role in the efficient operation of belt press machines used in various industries for dewatering and solid-liquid separation processes. Some of the key job responsibilities include:

1. Machine Operation and Maintenance

Operating belt press machines according to established procedures, ensuring optimal performance and product quality.

- Monitoring machine parameters, such as belt tension, feed rate, and filtrate clarity, to ensure efficient operation.

- Performing routine maintenance and troubleshooting minor issues to maintain the machine’s functionality and minimize downtime.

2. Sample Collection and Analysis

Collecting and analyzing samples of feed and filtrate to monitor process efficiency and ensure product quality.

- Conducting simple chemical or physical tests on samples to determine solids content, moisture levels, and other parameters.

- Interpreting test results and adjusting machine settings or process parameters as needed to optimize performance.

3. Process Control

Monitoring and controlling the belt press process to ensure efficient dewatering and solids capture.

- Adjusting feed rates, belt speeds, and other process parameters based on sample analysis and machine performance.

- Monitoring filtrate quality and taking corrective actions to maintain desired solids content and clarity.

4. Safety and Environmental Compliance

Adhering to safety protocols and environmental regulations related to the operation of belt press machines.

- Wearing appropriate personal protective equipment (PPE) and following established safety procedures.

- Monitoring filtrate disposal and ensuring compliance with environmental regulations.

Interview Tips

To ace an interview for a Belt-Press Operator position, it is crucial to prepare thoroughly and demonstrate your knowledge and skills. Here are some interview tips to help you succeed:

1. Research the Company and Position

Take the time to research the company you are applying to, including their industry, products or services, and company culture.

- Tailor your answers to the specific job requirements and highlight your relevant skills and experience.

- Show enthusiasm for the role and the company’s mission.

2. Practice Common Interview Questions

Prepare for common interview questions related to belt press operation, process control, and safety. Practice answering these questions clearly and concisely.

- Example Outline:

- – Tell me about your experience operating belt press machines.

- – How do you ensure optimal performance and product quality from a belt press?

- – Describe your approach to monitoring and controlling the belt press process.

- – What safety protocols do you follow when operating belt press machines?

3. Emphasize Your Problem-Solving Skills

Belt-Press Operators often encounter unexpected issues during machine operation. Highlight your ability to troubleshoot problems, analyze data, and find solutions.

- Provide specific examples from your previous experience where you successfully resolved issues related to belt press operation.

- Explain your logical thought process and the steps you took to identify and fix the problem.

4. Demonstrate Your Commitment to Safety and Compliance

Emphasize your commitment to safety and compliance with environmental regulations.

- Explain your understanding of the safety protocols and environmental regulations related to belt press operation.

- Describe your experience in following these protocols and ensuring compliance.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Belt-Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.