Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Belt Splicer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

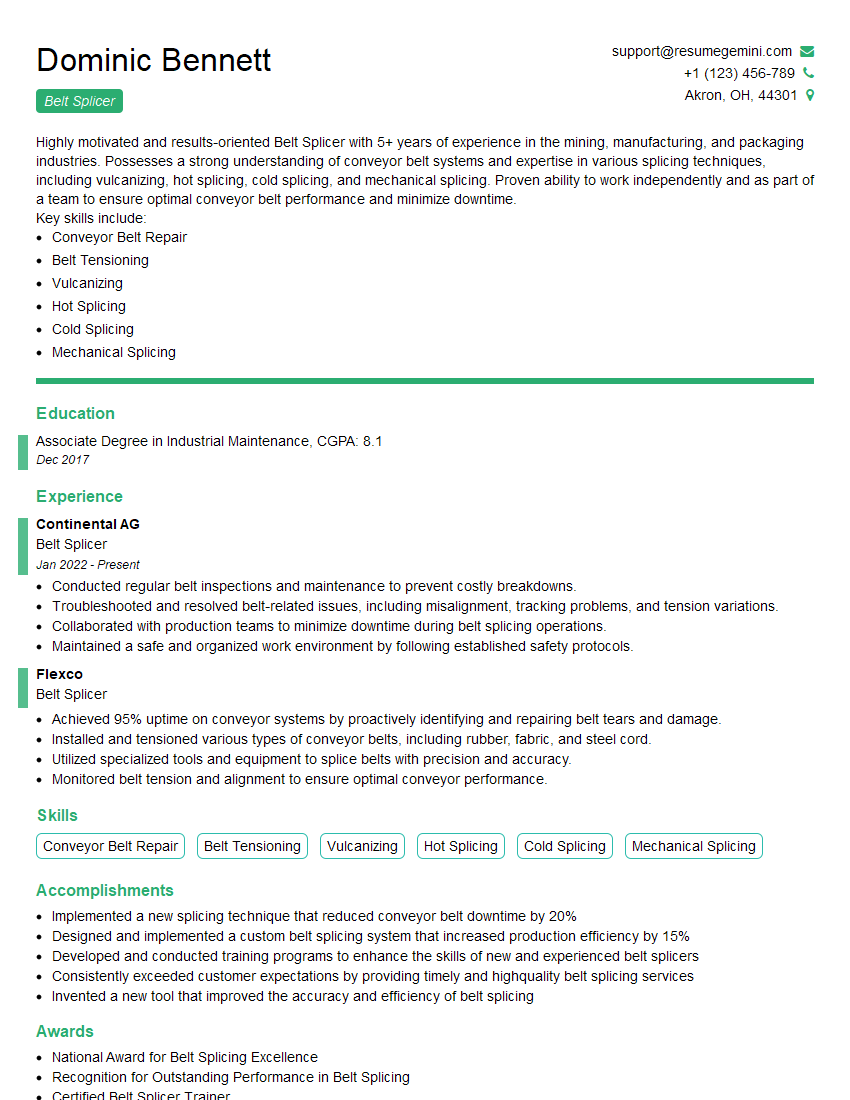

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belt Splicer

1. Describe the steps involved in splicing a conveyor belt?

- Prepare the belt ends by squaring them off and removing any damaged or frayed edges.

- Align the belt ends and apply a layer of splicing cement to each end.

- Press the belt ends together and allow the cement to dry.

- Apply a second layer of splicing cement and press the belt ends together again.

- Allow the cement to dry completely before putting the belt back into operation.

2. What are the different types of conveyor belt splices?

Mechanical Splices

- Finger Splices: These splices use interlocking fingers to join the belt ends.

- Bolt Splices: These splices use bolts to hold the belt ends together.

- Clamp Splices: These splices use clamps to hold the belt ends together.

Vulcanized Splices

- Hot Vulcanized Splices: These splices use heat and pressure to bond the belt ends together.

- Cold Vulcanized Splices: These splices use a chemical reaction to bond the belt ends together.

3. What are the advantages and disadvantages of each type of splice?

- Mechanical Splices:

- Advantages: Easy to install, relatively inexpensive.

- Disadvantages: Not as strong as vulcanized splices, can be noisy.

- Vulcanized Splices:

- Advantages: Strong, durable, quiet.

- Disadvantages: More difficult to install, more expensive.

4. What is the most common type of splice used in the conveyor belt industry?

Vulcanized splices are the most common type of splice used in the conveyor belt industry. They are strong, durable, and quiet, making them ideal for use in high-demand applications.

5. What are the safety precautions that must be taken when splicing a conveyor belt?

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Make sure the conveyor belt is de-energized and locked out before starting work.

- Use sharp tools and be careful not to cut yourself.

- Be aware of your surroundings and be careful not to trip or fall.

- Follow all manufacturer’s instructions for the splicing equipment.

6. What are the most common problems that can occur when splicing a conveyor belt?

- Misalignment of the belt ends

- Insufficient overlap of the belt ends

- Improper application of splicing cement

- Insufficient drying time for the splicing cement

- Overheating of the belt ends during the splicing process

7. How can these problems be prevented?

- Use a belt alignment tool to ensure that the belt ends are properly aligned.

- Overlap the belt ends by at least 4 inches.

- Apply splicing cement evenly to both belt ends.

- Allow the splicing cement to dry completely before putting the belt back into operation.

- Use a temperature probe to monitor the temperature of the belt ends during the splicing process.

8. What is the importance of proper belt splicing?

Proper belt splicing is important for ensuring the safety and efficiency of a conveyor system. A poorly spliced belt can lead to a number of problems, including:

- Belt breakage

- Material spillage

- Equipment damage

- Production downtime

9. What are the different types of belt splicing equipment?

- Belt presses

- Vulcanizing presses

- Splicing machines

- Hand tools

10. What are the factors that should be considered when selecting belt splicing equipment?

- The type of belt being spliced

- The width and thickness of the belt

- The desired splice strength

- The available budget

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belt Splicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belt Splicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Belt Splicer is a skilled professional responsible for maintaining and repairing conveyor belts in various industries. They play a crucial role in ensuring the smooth operation of conveyor systems and preventing costly downtime.

1. Belt Maintenance and Repair

Inspect conveyor belts regularly for any signs of damage, wear, or defects.

- Repair or replace damaged sections of belts using specialized splicing techniques.

- Monitor belt tension and alignment to ensure optimal performance.

2. Vulcanizing and Joining

Prepare belt ends for splicing by removing old material and cleaning the surfaces.

- Apply heat and pressure to vulcanize and join belt sections using specialized equipment.

- Ensure proper bonding and curing of the splice for maximum strength and durability.

3. Troubleshooting

Diagnose and troubleshoot conveyor belt issues, including misalignment, tension problems, and material buildup.

- Identify the root cause of belt failures and implement corrective measures.

- Work closely with other maintenance personnel to resolve complex issues.

4. Safety

Follow established safety procedures and wear appropriate personal protective equipment (PPE).

- Operate machinery safely and ensure that work areas are free from hazards.

- Monitor conveyor systems for any potential safety concerns and take appropriate action.

Interview Tips

Preparing thoroughly for a Belt Splicer interview can significantly increase your chances of making a positive impression. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company’s industry, products, or services, and specific requirements for the belt splicer position. This will demonstrate your interest and knowledge of the role.

- Visit the company website and read online articles or news about their operations.

- Check industry-specific publications to understand the company’s position in the market.

2. Highlight Your Technical Skills

Emphasize your proficiency in belt splicing techniques, including vulcanizing and mechanical splicing. Provide specific examples of your experience and the outcomes you achieved.

- Describe the types of conveyor systems you have worked on and the challenges you faced.

- Showcase your knowledge of different belt materials and their applications.

3. Demonstrate Problem-Solving Abilities

Share instances where you successfully diagnosed and resolved conveyor belt issues. Explain your troubleshooting process and the solutions you implemented.

- Highlight your ability to work independently and collaborate effectively with others.

- Discuss how you prioritize tasks and manage your time efficiently.

4. Emphasize Safety Awareness

Stress your commitment to safety and adherence to established protocols. Provide examples of how you ensure the safety of yourself and others in the workplace.

- Explain your understanding of industry safety regulations and best practices.

- Share your experience in conducting safety inspections and maintaining a safe work environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Belt Splicer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Belt Splicer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.