Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Belting and Webbing Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Belting and Webbing Inspector so you can tailor your answers to impress potential employers.

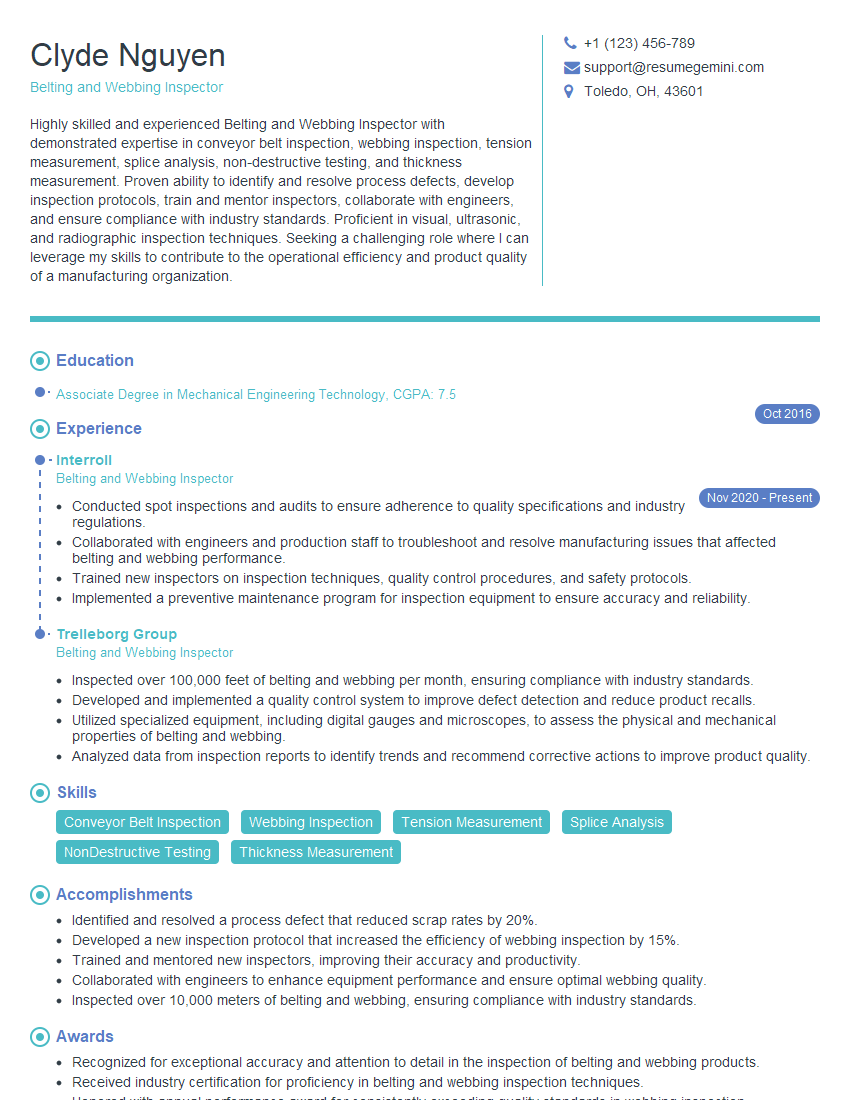

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Belting and Webbing Inspector

1. What are the key responsibilities of a Belting and Webbing Inspector?

As a Belting and Webbing Inspector, I would be responsible for ensuring the quality of belting and webbing products by performing various inspections and tests. This would include:

- Inspecting raw materials for defects, dimensions, and compliance with specifications

- Conducting in-process inspections of belting and webbing products to ensure they meet specifications and quality standards

- Performing final inspections of finished products to verify their overall quality and performance

2. What are the different types of belting and webbing materials?

Natural fibers

- Cotton

- Linen

Synthetic fibers

- Nylon

- Polyester

- Polypropylene

Metal

- Steel

- Stainless steel

3. What are the different types of belting and webbing constructions?

The two main types of belting and webbing constructions are:

- Woven: This type of construction involves interlacing warp and weft yarns to create a fabric

- Knitted: This type of construction involves looping yarns together to create a fabric

4. What are the different types of tests that you perform on belting and webbing products?

The types of tests that I perform on belting and webbing products include:

- Tensile strength tests to measure the force required to break the product

- Elongation tests to measure the amount of stretch in the product

- Tear resistance tests to measure the force required to tear the product

5. What are the quality standards that you follow when inspecting belting and webbing products?

The quality standards that I follow when inspecting belting and webbing products include:

- ISO 9001:2015

- ASME B18.2.1

- ASTM D4734

6. What are the common defects that you look for when inspecting belting and webbing products?

The common defects that I look for when inspecting belting and webbing products include:

- Broken or damaged fibers

- Holes or tears

- Uneven or inconsistent weaving or knitting

7. What is your experience with using inspection equipment such as calipers, micrometers, and gauges?

I have experience using a variety of inspection equipment, including:

- Calipers to measure the dimensions of belting and webbing products

- Micrometers to measure the thickness of belting and webbing products

- Gauges to measure the tension of belting and webbing products

8. How do you stay up-to-date on the latest belting and webbing inspection techniques?

I stay up-to-date on the latest belting and webbing inspection techniques by:

- Reading industry publications

- Attending industry conferences

- Taking online courses

9. What are your strengths as a Belting and Webbing Inspector?

My strengths as a Belting and Webbing Inspector include:

- My attention to detail

- My ability to identify and resolve quality issues

- My experience with a variety of inspection equipment

10. What are your weaknesses as a Belting and Webbing Inspector?

My weaknesses as a Belting and Webbing Inspector include:

- My lack of experience with some of the more advanced inspection techniques

- My tendency to be overly critical of my own work

- My impatience with repetitive tasks

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Belting and Webbing Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Belting and Webbing Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Belting and Webbing Inspectors are responsible for ensuring that the quality of belting and webbing meets the required standards.

1. Inspecting Belting and Webbing

Inspecting belting and webbing for defects, such as tears, holes, and fraying.

- Identifying and classifying defects according to established criteria.

- Measuring and recording the dimensions and weight of belting and webbing.

2. Testing Belting and Webbing

Testing belting and webbing to determine their strength, durability, and resistance to wear and tear.

- Performing tensile strength tests, elongation tests, and tear resistance tests.

- Analyzing test results and comparing them to established specifications.

3. Maintaining Inspection Records

Maintaining detailed records of all inspections and tests performed.

- Documenting defects, measurements, and test results.

- Submitting inspection reports to supervisors and quality control personnel.

4. Monitoring Production Processes

Monitoring production processes to ensure that belting and webbing are manufactured according to specifications.

- Identifying and correcting potential problems in the production process.

- Providing feedback to production personnel on quality control measures.

Interview Tips

Preparing for an interview for a Belting and Webbing Inspector position requires research, practice, and a strong understanding of the industry.

1. Research the Company and the Role

Read the job description carefully and research the company’s website to learn about their products, services, and values.

- This will help you understand the specific requirements of the role and tailor your answers to the interviewer’s questions.

- For example, if the job description emphasizes the importance of quality control, you could highlight your experience in implementing and maintaining quality control systems.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and qualifications.

- For example, you may be asked to describe your experience in inspecting belting and webbing, or to explain how you would handle a situation where you identified a defect in a product.

- Practice answering these questions concisely and clearly, providing specific examples to support your claims.

3. Highlight Your Relevant Skills and Experience

Emphasize your skills and experience that are most relevant to the Belting and Webbing Inspector role.

- For example, if the job description requires experience in tensile strength testing, be sure to highlight your expertise in this area.

- You can also mention any certifications or training you have received that are related to belting and webbing inspection.

4. Be Prepared to Discuss Quality Control Measures

Interviewers will want to know your understanding of quality control measures and how you implement them in your work.

- Be prepared to discuss the different types of quality control measures you have used, such as statistical process control, visual inspection, and sampling.

- Explain how you use these measures to ensure that belting and webbing meet the required standards.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Belting and Webbing Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.