Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bench Grinder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bench Grinder so you can tailor your answers to impress potential employers.

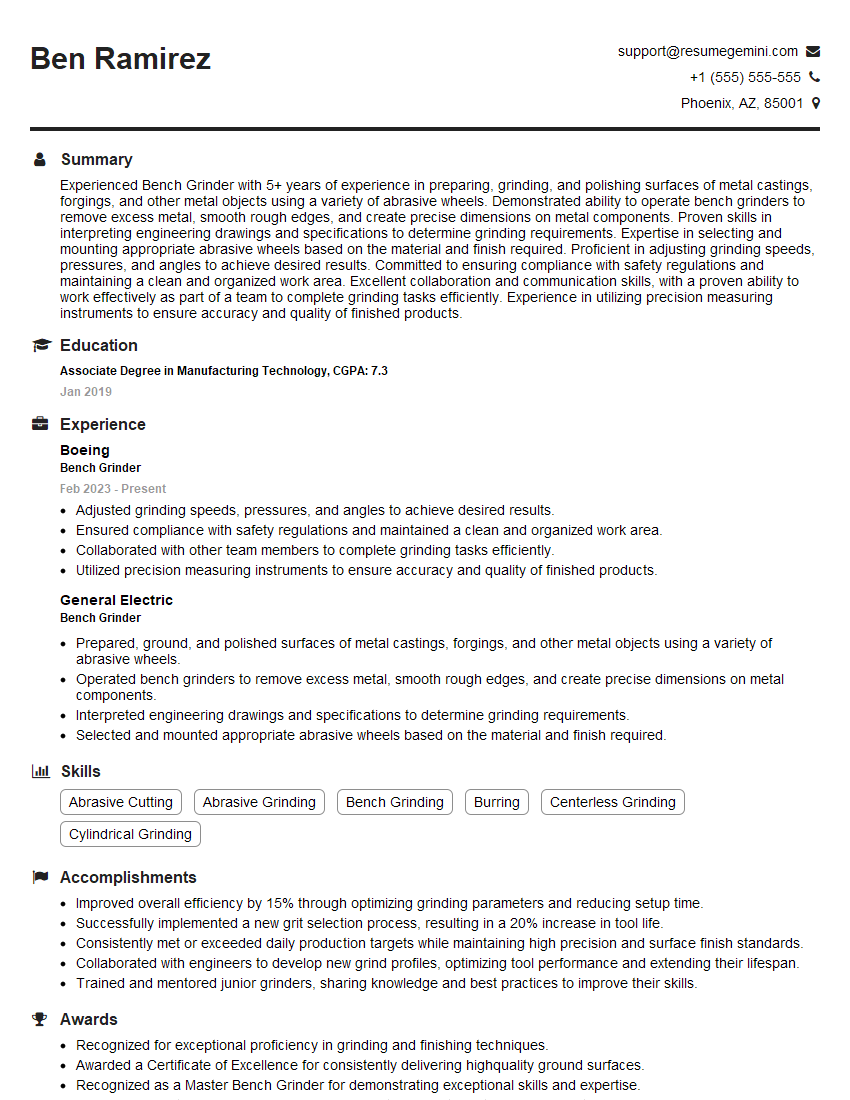

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bench Grinder

1. What are the different types of bench grinders available?

There are two main types of bench grinders:

- Pedestal grinders: These grinders are mounted on a pedestal and have a large, heavy base. They are typically used for heavy-duty grinding operations.

- Bench grinders: These grinders are mounted on a bench or table and are smaller and lighter than pedestal grinders. They are typically used for light-duty grinding operations.

2. What are the different types of grinding wheels that can be used on a bench grinder?

Types of abrasives

- Aluminum oxide

- Silicon carbide

- Ceramic

- Cubic boron nitride

- Diamond

Types of bonds

- Vitrified

- Resinoid

- Shellac

- Rubber

- Metal

3. How do you select the right grinding wheel for a particular application?

The type of grinding wheel to use depends on the material being ground, the desired finish, and the speed of the grinder. The following factors should be considered when selecting a grinding wheel:

- Material being ground: The type of abrasive in the grinding wheel must be compatible with the material being ground. For example, aluminum oxide wheels are typically used for grinding ferrous metals, while silicon carbide wheels are typically used for grinding non-ferrous metals.

- Desired finish: The grit size of the grinding wheel determines the finish of the ground surface. A finer grit wheel will produce a smoother finish than a coarser grit wheel.

- Speed of the grinder: The speed of the grinder must be compatible with the grinding wheel. A grinding wheel that is operated at too high a speed can break apart, while a grinding wheel that is operated at too low a speed will not grind effectively.

4. How do you dress a grinding wheel?

Dressing a grinding wheel is the process of removing the glaze from the wheel and exposing new abrasive. Dressing a grinding wheel can be done with a diamond dresser, a carbide dresser, or a silicon carbide dresser. The type of dresser to use depends on the type of grinding wheel being dressed.

5. How do you safely operate a bench grinder?

To safely operate a bench grinder, the following precautions should be taken:

- Wear eye protection: Grinding wheels can shatter, so it is important to wear eye protection when operating a bench grinder.

- Wear ear protection: Bench grinders can be noisy, so it is important to wear ear protection when operating one.

- Use the proper grinding wheel: The type of grinding wheel being used must be compatible with the material being ground.

- Dress the grinding wheel regularly: The grinding wheel should be dressed regularly to remove the glaze and expose new abrasive.

- Use a push stick: A push stick should be used to hold the workpiece against the grinding wheel.

- Keep the work area clean: The work area should be kept clean to prevent tripping hazards.

6. What are some common problems that can occur when using a bench grinder?

- The grinding wheel breaks: This can occur if the grinding wheel is operated at too high a speed, if the grinding wheel is not properly dressed, or if the grinding wheel is damaged.

- The workpiece is burned: This can occur if the grinding wheel is operated at too high a speed or if the workpiece is held against the grinding wheel for too long.

- The grinding wheel chatters: This can occur if the grinding wheel is not properly dressed or if the workpiece is not held securely against the grinding wheel.

7. How do you troubleshoot a bench grinder?

If a bench grinder is not working properly, the following troubleshooting steps can be taken:

- Check the power supply: Make sure that the bench grinder is plugged into a working power outlet.

- Check the grinding wheel: Make sure that the grinding wheel is properly mounted and that it is not damaged.

- Dress the grinding wheel: Dress the grinding wheel to remove the glaze and expose new abrasive.

- Adjust the speed of the grinder: The speed of the grinder should be adjusted to match the material being ground.

8. What are some tips for getting the most out of a bench grinder?

- Use the proper grinding wheel: The type of grinding wheel being used must be compatible with the material being ground.

- Dress the grinding wheel regularly: The grinding wheel should be dressed regularly to remove the glaze and expose new abrasive.

- Use a push stick: A push stick should be used to hold the workpiece against the grinding wheel.

- Keep the work area clean: The work area should be kept clean to prevent tripping hazards.

- Follow the manufacturer’s instructions: The manufacturer’s instructions should be followed for the specific bench grinder being used.

9. What are some of the safety precautions that should be taken when using a bench grinder?

- Wear eye protection: Grinding wheels can shatter, so it is important to wear eye protection when operating a bench grinder.

- Wear ear protection: Bench grinders can be noisy, so it is important to wear ear protection when operating one.

- Use the proper grinding wheel: The type of grinding wheel being used must be compatible with the material being ground.

- Dress the grinding wheel regularly: The grinding wheel should be dressed regularly to remove the glaze and expose new abrasive.

- Use a push stick: A push stick should be used to hold the workpiece against the grinding wheel.

- Keep the work area clean: The work area should be kept clean to prevent tripping hazards.

10. What are some of the different types of materials that can be ground using a bench grinder?

- Metal

- Wood

- Plastic

- Ceramic

- Glass

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bench Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bench Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bench Grinders are responsible for operating and maintaining grinding machines to grind and shape metal objects. They must be able to read and interpret blueprints and drawings, and have a good understanding of the principles of grinding. Key job responsibilities include:

1. Operating and maintaining grinding machines

Bench Grinders must be able to operate and maintain a variety of grinding machines, including bench grinders, pedestal grinders, and surface grinders. They must be able to adjust the machine settings to achieve the desired results, and must be able to troubleshoot and repair any problems that may occur.

- Perform routine maintenance on grinding machines, such as cleaning, lubricating, and replacing worn parts.

- Inspect and test grinding wheels to ensure they are in good condition.

2. Grinding and shaping metal objects

Bench Grinders must be able to grind and shape metal objects to precise specifications. They must be able to use a variety of grinding wheels and abrasives to achieve the desired results.

- Grind and shape metal objects to precise specifications using a variety of grinding wheels and abrasives.

- Deburr and polish metal objects.

3. Reading and interpreting blueprints and drawings

Bench Grinders must be able to read and interpret blueprints and drawings to understand the specifications for the metal objects they are grinding. They must be able to identify the dimensions, tolerances, and surface finishes required.

- Read and interpret blueprints and drawings to determine the specifications for the metal objects to be ground.

- Identify the dimensions, tolerances, and surface finishes required.

4. Maintaining a safe work environment

Bench Grinders must be able to maintain a safe work environment. They must be familiar with the safety regulations for working with grinding machines, and must be able to identify and avoid potential hazards.

- Maintain a safe work environment by following all safety regulations.

- Identify and avoid potential hazards.

Interview Tips

Preparing for a Bench Grinder interview can be daunting, but with the right strategies, you can increase your chances of success. Here are ten tips to help you ace your interview:

1. Research the company and the position

Before you go to your interview, take some time to learn about the company and the position you are applying for. This will help you answer questions intelligently and show the interviewer that you are genuinely interested in the job.

- Visit the company website to learn about their history, mission, and values.

- Read job postings and descriptions carefully to understand the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a brief introduction of yourself, including your skills and experience.

- Think about why you are interested in the position and the company, and how your skills and experience align with the job requirements.

3. Be prepared to talk about your experience

The interviewer will likely ask you about your experience working with grinding machines. Be prepared to discuss your skills and experience in detail, and provide specific examples of your work.

- Highlight your experience operating and maintaining grinding machines.

- Describe your experience grinding and shaping metal objects to precise specifications.

4. Be prepared to answer questions about safety

The interviewer will also likely ask you about your safety knowledge and experience. Be prepared to discuss your understanding of the safety regulations for working with grinding machines, and provide specific examples of how you have maintained a safe work environment.

- Describe your understanding of the safety regulations for working with grinding machines.

- Provide examples of how you have maintained a safe work environment.

5. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and positive about the position. Be sure to show your interest in the job and the company, and be positive about your skills and experience.

- Smile and make eye contact with the interviewer.

- Be enthusiastic and positive about your skills and experience.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bench Grinder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.