Are you gearing up for an interview for a Bench Hand position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bench Hand and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

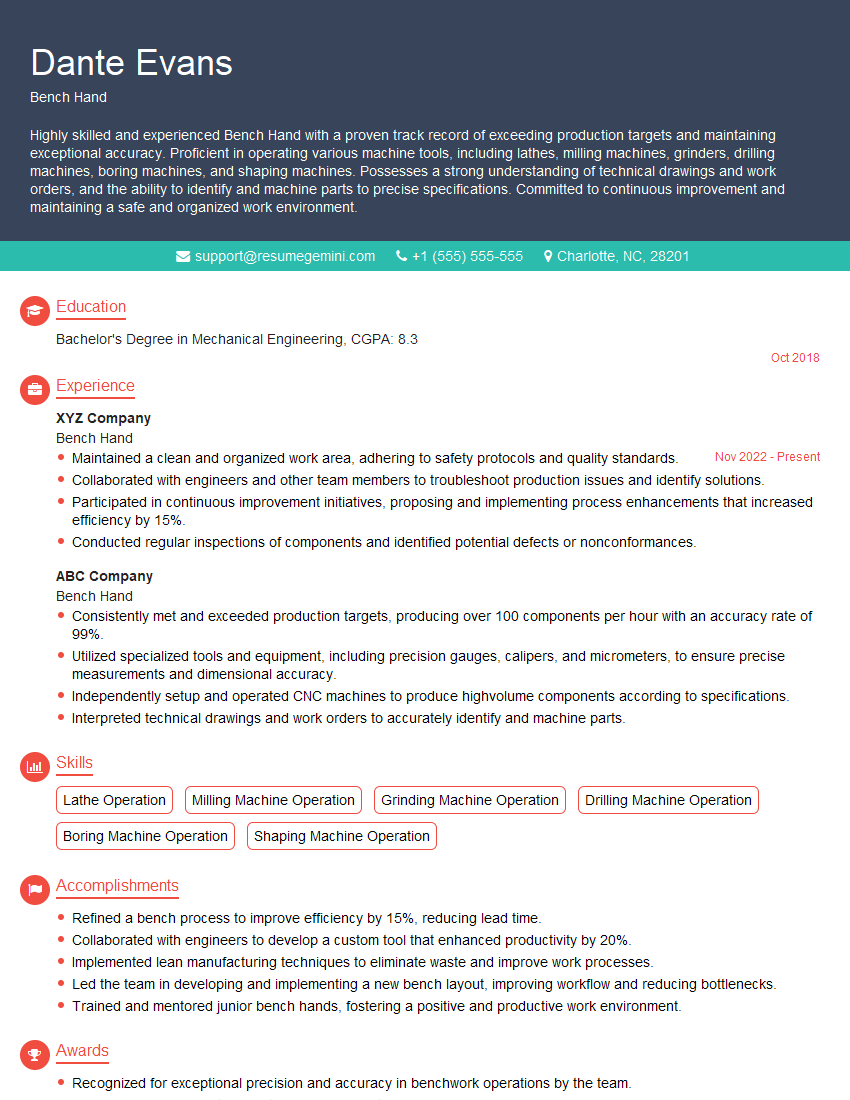

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bench Hand

1. Describe the steps you take to set up a bench for a specific job?

When setting up a bench for a specific job, I follow these steps:

- Gather the necessary tools and materials for the job.

- Clean and prepare the bench surface to ensure it is free from debris and contaminants.

- Position the workpiece securely on the bench using clamps or other holding devices.

- Adjust the lighting and magnification as needed for the task.

- Set up any specialized equipment or jigs required for the job.

2. How do you ensure that your work meets the required specifications?

To ensure that my work meets the required specifications, I follow these practices:

Quality Control Procedures

- Reviewing the specifications thoroughly before starting the job.

- Using measuring tools and gauges to verify dimensions and tolerances.

- Conducting visual inspections to identify any defects or imperfections.

Attention to Detail

- Paying close attention to the details of the job.

- Taking my time and avoiding rushing through the work.

- Double-checking my work before submitting it.

3. Explain the different types of bench tools you use and their applications?

I am familiar with a wide range of bench tools, including:

- Measuring tools: Calipers, micrometers, rulers, protractors

- Cutting tools: Saws, knives, shears

- Forming tools: Hammers, pliers, wrenches

- Finishing tools: Files, sandpaper, polishing wheels

- Specialized tools: Jigs, fixtures, vises

I understand the proper use and applications of each tool, ensuring that I select the right tool for the job and use it safely and effectively.

4. How do you handle and store tools and equipment properly?

I place a high value on the proper handling and storage of tools and equipment to ensure their longevity and safety:

- Handling: I handle tools with care, avoiding dropping or mishandling them.

- Cleaning: I clean tools after each use to remove debris and prevent corrosion.

- Sharpening: I sharpen tools regularly to maintain their cutting edges.

- Storage: I store tools in their designated places, ensuring they are protected from damage and easy to find.

5. Give an example of a time when you had to troubleshoot a bench-related issue and how you resolved it?

I once encountered an issue where a workpiece was not being held securely on the bench during a drilling operation. To troubleshoot:

- Inspection: I inspected the clamp and noticed it was loose.

- Adjustment: I tightened the clamp to secure the workpiece.

- Re-testing: I re-tested the setup and confirmed that the workpiece was now held securely.

6. How do you maintain a clean and organized work area?

Maintaining a clean and organized work area is crucial for safety and efficiency:

- Regular cleaning: I clean my work area regularly, removing debris and spills.

- Designated storage: I have designated storage areas for tools, materials, and equipment.

- 5S principles: I apply 5S principles (sort, straighten, shine, standardize, sustain) to maintain a clutter-free and organized workspace.

7. Describe your experience with different types of materials and how you work with them?

I have experience working with a variety of materials, including:

- Metals: Steel, aluminum, brass, copper

- Plastics: ABS, PVC, polyethylene

- Wood: Hardwoods, softwoods, plywood

- Composites: Fiberglass, carbon fiber

I understand the properties and characteristics of each material and adjust my work techniques accordingly.

8. What safety precautions do you take when working on the bench?

Safety is my top priority when working on the bench:

- PPE: I wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection.

- Proper setup: I ensure that my work area is well-lit and has adequate ventilation.

- Tool safety: I inspect tools before use and operate them safely.

- Housekeeping: I maintain a clean and organized work area to prevent accidents.

9. How do you communicate with others in the workplace, especially when working on a team project?

Effective communication is essential in a team environment:

- Active listening: I listen attentively to instructions and feedback.

- Clear communication: I convey my ideas and questions clearly and concisely.

- Collaboration: I actively participate in discussions and contribute to decision-making.

- Respect: I treat my colleagues with respect and consider their perspectives.

10. What do you enjoy most about working as a Bench Hand?

I find the following aspects of Bench Hand work particularly enjoyable:

- Hands-on nature: I enjoy the practical, hands-on aspect of the job.

- Variety: Each job brings its own unique challenges and variety.

- Attention to detail: I take pride in producing high-quality work that meets specifications.

- Problem-solving: Troubleshooting and finding solutions to technical problems is satisfying.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bench Hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bench Hand‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Bench Hand is accountable for working on a variety of tasks in a manufacturing setting. Key responsibilities of the role include:

1. Production Support

Assisting with the production process, including material handling, equipment setup and operation, and product assembly and finishing.

2. Equipment Operation

Operating and maintaining various types of equipment, such as lathes, drills, grinders, and saws, to produce or modify parts and products.

3. Quality Control

Ensuring product quality by inspecting and testing finished products, identifying and correcting defects, and adhering to quality standards.

4. Safety and Maintenance

Maintaining a safe and clean work environment, following established safety protocols, and conducting routine maintenance and repairs on equipment.

Interview Tips

To ace the interview for the Bench Hand position, follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and culture, and tailor your answers to demonstrate your interest and knowledge of the role.

2. Highlight Relevant Skills and Experience

Emphasize your prior experience in a manufacturing environment, particularly in the operation of equipment and quality control measures.

3. Prepare for Technical Questions

Review basic mechanical principles, equipment operation, and quality control techniques to answer technical questions confidently.

4. Demonstrate Problem-Solving Abilities

Provide examples of how you have identified and resolved production issues or equipment malfunctions in the past.

5. Show Safety Consciousness

Stress your commitment to safety and explain your experience in adhering to safety protocols and maintaining a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bench Hand interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!