Feeling lost in a sea of interview questions? Landed that dream interview for Bench Jeweler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bench Jeweler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

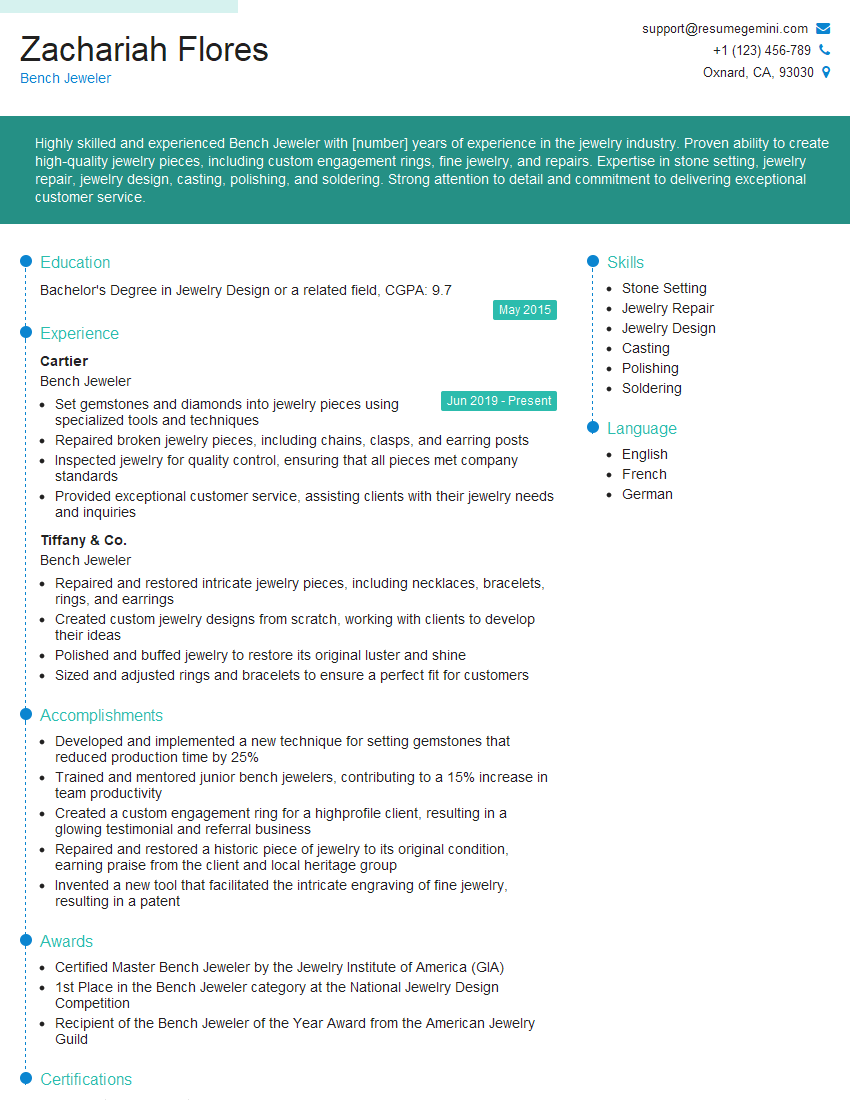

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bench Jeweler

1. Describe the process of setting a stone in a bezel setting.

In a bezel setting, the stone is held in place by a metal rim that surrounds it. Here’s the process:

- Prepare the bezel: Create a bezel cup with the correct diameter to hold the stone securely.

- Prepare the stone: Clean the stone to remove any debris.

- Apply flux to the stone: Apply flux to the base of the stone to improve adhesion.

- Place the stone in the bezel: Carefully place the stone into the bezel cup.

- Solder the bezel: Use solder to secure the bezel around the stone, filling any gaps between the metal and stone.

- Cut off excess bezel: Remove any excess bezel material that extends beyond the stone.

2. How would you repair a broken chain?

Soldering

- Line up the broken ends of the chain securely.

- Apply flux to the joint area.

- Solder the joint, melting the metal to fuse the ends together.

Laser Welding

- Position the broken chain ends with precision.

- Use a laser to create a narrow, focused beam of heat.

- Direct the laser beam onto the joint, melting and fusing the metal.

Mechanical Repair

- For rings, a jump ring can be added to connect the broken ends.

- For bracelets or necklaces, a clasp or connector can be attached to the ends to form a secure closure.

3. What techniques can you use to create intricate wirework?

- Wire Wrapping: Wrapping wire around itself or other objects to create loops, coils, and spirals.

- Wire Weaving: Interlacing multiple strands of wire to form patterns, such as herringbone or basket weave.

- Wire Coiling: Coiling wire into loops or spirals, then soldering or gluing them together.

- Wire Bending: Using tools or pliers to shape and bend wire into various forms.

- Wire Filigree: Creating delicate and intricate designs by soldering or gluing fine wire scrolls and shapes together.

4. How do you determine the correct alloy for a specific piece of jewelry?

- Intended Use: Consider the purpose and wearability of the piece, such as for everyday wear, special occasions, or rough conditions.

- Durability: Some alloys, like platinum or 18k gold, offer greater durability and resistance to wear and tear.

- Color and Finish: Different alloys produce varying colors and finishes, such as white gold, yellow gold, or rose gold.

- Allergy Considerations: Nickel-free alloys are important for individuals with allergies or sensitivities.

- Cost: The price of alloys varies depending on their composition and rarity.

5. Explain the process of casting a piece of jewelry.

Lost-Wax Casting

- Create a wax model of the desired design.

- Build a mold around the wax model.

- Melt metal and pour it into the mold, replacing the wax.

- Break away the mold to reveal the cast piece.

Centrifugal Casting

- Create a wax or plastic model of the design.

- Attach it to a sprue and place it in a rotating flask.

- Pour molten metal into the flask, using centrifugal force to push it into the mold.

Investment Casting

- Create a wax model of the design.

- Suspend it in an investment material and heat it.

- Pour molten metal into the investment, replacing the wax.

- Break away the investment to reveal the cast piece.

6. How would you polish and finish a piece of jewelry?

Polishing

- Use abrasive materials (e.g., sandpaper, polishing wheels) to remove surface imperfections.

- Start with coarse abrasives and gradually move to finer grits.

- Polish with various compounds and brushes to achieve a desired shine.

Finishing

- Apply a protective coating (e.g., lacquer, rhodium plating) to prevent tarnishing.

- Use hammers, pliers, and other tools to adjust the shape and fit.

- Add decorative elements (e.g., engraving, gemstones) to enhance the design.

7. How do you ensure the quality of your work?

- Attention to Detail: I meticulously examine each piece for imperfections and ensure it meets the required standards.

- Quality Control Processes: I have established quality control checkpoints throughout the production process to identify and correct any potential issues.

- Regular Training: I continuously update my skills and knowledge through training and workshops to stay abreast of industry best practices.

- Customer Feedback: I value customer feedback and use it to improve my techniques and refine my designs.

8. What is your experience working with different types of jewelry materials?

- Precious Metals: Gold, platinum, silver – skilled in soldering, forming, and polishing.

- Base Metals: Brass, copper, bronze – proficient in casting, etching, and patina techniques.

- Gemstones: Diamonds, rubies, sapphires – experienced in setting, cutting, and polishing.

- Pearls: Natural and cultured – familiar with stringing, knotting, and mounting techniques.

- Organic Materials: Leather, wood, bone – experienced in incorporating these materials into jewelry designs.

9. How do you stay up-to-date with the latest trends in jewelry design?

- Industry Publications: Subscribe to magazines and online forums dedicated to jewelry design.

- Fashion Shows and Exhibitions: Attend events showcasing the latest collections and trends.

- Social Media: Follow industry influencers and designers on social media platforms for inspiration.

- Continuing Education: Enroll in workshops and courses to expand my knowledge and skills.

- Museum Visits: Explore historical jewelry collections to appreciate past design styles and techniques.

10. Tell me about a challenging jewelry repair you’ve encountered and how you resolved it.

In one instance, I encountered a badly damaged engagement ring with several broken prongs and a loose gemstone. To resolve it:

- Assessment: I carefully examined the ring to determine the extent of the damage.

- Prong Repair: I used a laser welder to repair the broken prongs, ensuring they securely held the gemstone.

- Gemstone Setting: I reset the gemstone using a bezel setting to provide additional protection.

- Polishing and Finishing: I meticulously polished and finished the ring to restore its original luster.

- Customer Satisfaction: The customer was delighted with the repaired ring, and it was a rewarding experience to restore its sentimental value.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bench Jeweler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bench Jeweler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bench jewelers are skilled artisans who create and repair jewelry using a variety of tools and techniques. They typically work in a retail setting, such as a jewelry store or department store, and may also work in a private studio.

1. Create new jewelry

Bench jewelers use a variety of materials, including gold, silver, platinum, and gemstones, to create new pieces of jewelry. They may work from sketches or designs, or they may create their own original designs.

- Use a variety of tools and techniques to create jewelry, such as soldering, casting, and stone setting.

- Work from sketches or designs to create jewelry, or create their own original designs.

2. Repair jewelry

Bench jewelers also repair jewelry, such as fixing broken clasps, soldering broken chains, and resetting loose stones. They may also perform other tasks, such as cleaning and polishing jewelry.

- Repair jewelry, such as fixing broken clasps, soldering broken chains, and resetting loose stones.

- Perform other tasks, such as cleaning and polishing jewelry.

3. Advise customers

Bench jewelers may also advise customers on jewelry care and repair, and help them select the right piece of jewelry for their needs.

- Advise customers on jewelry care and repair.

- Help customers select the right piece of jewelry for their needs.

4. Maintain a clean and organized work area

Bench jewelers must maintain a clean and organized work area in order to avoid accidents and ensure the quality of their work.

- Maintain a clean and organized work area.

- Follow safety protocols to avoid accidents.

Interview Tips

Preparing for a bench jeweler interview can help you make a good impression and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture and values, and it will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their history, products, and services.

- Read online reviews of the company to get an idea of what it’s like to work there.

- Search for the position you’re applying for on LinkedIn to see what skills and experience the company is looking for.

2. Practice answering common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions in advance so that you can feel confident and prepared during your interview.

- Use the STAR method to answer interview questions.

- Be concise and to the point in your answers.

- Tailor your answers to the specific position you’re applying for.

3. Bring a portfolio of your work

If you have a portfolio of your work, be sure to bring it with you to your interview. This will give the interviewer a chance to see your skills and craftsmanship firsthand.

- Include a variety of pieces in your portfolio, such as jewelry you’ve created, repaired, and restored.

- Make sure your portfolio is well-organized and easy to navigate.

- Be prepared to talk about your portfolio and the techniques you used to create the pieces.

4. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or business casual attire.

- Wear a suit or business casual attire to your interview.

- Make sure your clothes are clean and pressed.

- Accessorize with a portfolio or briefcase.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bench Jeweler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!