Are you gearing up for a career in Bench Molder Apprentice? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bench Molder Apprentice and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

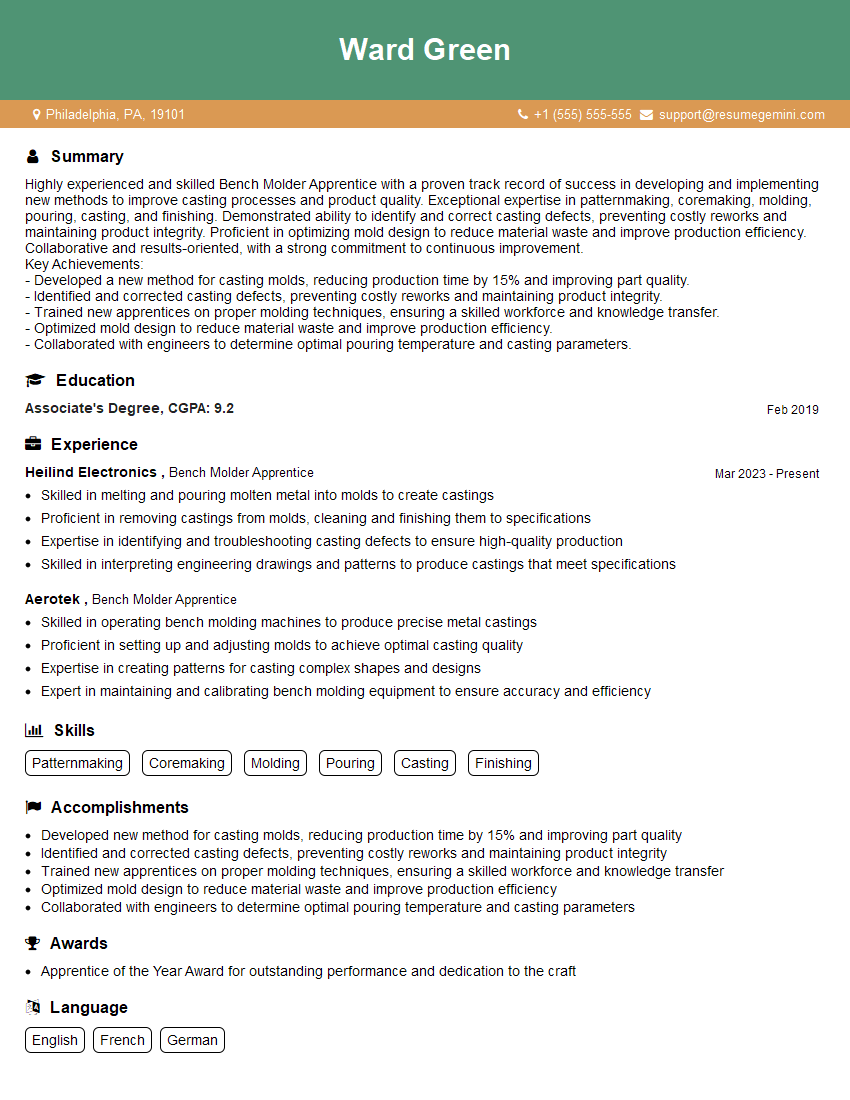

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bench Molder Apprentice

1. What is the purpose of a bench molder?

A bench molder is used to create molds for various purposes, such as casting metal or plastic. It is a versatile machine that can be used to create a wide range of shapes and sizes. The bench molder is composed of a worktable, a mold box, and a pattern. The pattern is the desired shape of the mold, and it is placed in the mold box. The molten metal or plastic is then poured into the mold box, and it takes the shape of the pattern. Once the metal or plastic has cooled and solidified, the mold is opened and the finished product is removed.

2. What are the different types of bench molders?

Manually operated bench molders

- Manually operated bench molders are the most basic type of bench molder. They are operated by hand, and they require the user to have a high degree of skill and experience.

- Manually operated bench molders are typically used for small-scale production runs.

Semi-automatic bench molders

- Semi-automatic bench molders are more advanced than manually operated bench molders. They are equipped with a motor that powers the mold box, and they can be used to create larger molds.

- Semi-automatic bench molders are typically used for medium-scale production runs.

Automatic bench molders

- Automatic bench molders are the most advanced type of bench molder. They are fully automated, and they can be used to create large molds with a high degree of precision.

- Automatic bench molders are typically used for large-scale production runs.

3. What are the safety precautions that should be taken when operating a bench molder?

- Wear appropriate safety gear, including gloves, safety glasses, and a dust mask.

- Keep the work area clean and free of debris.

- Never operate the bench molder if it is not in good working condition.

- Follow the manufacturer’s instructions for operating the bench molder.

- Be aware of the potential hazards of the materials being used.

4. What are the different types of materials that can be used in a bench molder?

- Metal

- Plastic

- Ceramic

- Glass

- Composite materials

5. What are the different types of patterns that can be used in a bench molder?

- Wood

- Metal

- Plastic

- Wax

- Rubber

6. What are the different types of mold releases that can be used in a bench molder?

- Oil-based mold releases

- Water-based mold releases

- Wax-based mold releases

- Silicone-based mold releases

7. What are the different types of casting processes that can be used with a bench molder?

- Sand casting

- Investment casting

- Die casting

- Centrifugal casting

- Vacuum casting

8. What are the different types of finishes that can be applied to a casting?

- Polishing

- Buffing

- Electroplating

- Powder coating

- Painting

9. What are the different types of defects that can occur in a casting?

- Shrinkage cavities

- Cold shuts

- Gas porosity

- Sand inclusions

- Cracks

10. What are the different types of troubleshooting techniques that can be used to resolve problems with a bench molder?

- Checking the power supply

- Checking the hydraulic system

- Checking the mold box

- Checking the pattern

- Checking the mold release

- Checking the casting process

- Checking the finish

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bench Molder Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bench Molder Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bench Molder Apprentices play a critical role in the foundry industry by assisting skilled workers in mold production. Their responsibilities encompass a wide range of tasks, primarily focused on supporting molders in crafting molds for casting metal objects.

1. Foundry Operations and Material Handling

Apprentices are responsible for aiding molders in material handling and foundry operations, including transporting and preparing materials such as sand, metal, and binders.

- Transporting and preparing sand for mold making

- Assisting in the weighing and mixing of materials

2. Mold Preparation and Maintenance

Apprentices assist molders in preparing and maintaining molds, ensuring they meet specified dimensions and standards.

- Preparing mold boxes by cleaning and assembling

- Loading and packing molds with sand

3. Molding Techniques and Equipment

Apprentices learn various molding techniques and become proficient in operating molding equipment, such as molding machines and pattern plates.

- Assisting in the setting and drawing of patterns

- Operating molding machines to create mold cavities

4. Quality Control and Safety

Apprentices are involved in quality control processes, ensuring that molds meet specified standards. They also adhere to safety protocols to maintain a safe working environment.

- Inspecting molds for defects and dimensional accuracy

- Following safety regulations and wearing appropriate protective gear

Interview Tips

To ace the Bench Molder Apprentice interview, candidates should prepare thoroughly and demonstrate their interest in the foundry industry. Here are some tips to help them succeed:

1. Research the Foundry Industry and Company

Candidates should research the foundry industry, its processes, and the specific company they are interviewing with. This knowledge will enable them to speak intelligently about the field and show genuine interest.

- Learn about different types of foundries and their casting processes

- Study the company’s website and gather information about their products and services

2. Highlight Relevant Skills and Experience

Candidates should emphasize skills and experience that align with the job responsibilities of a Bench Molder Apprentice. If they have worked in a similar role or have hands-on experience in the foundry industry, they should highlight these qualifications.

- Share examples of assisting in mold preparation, handling materials, or operating molding equipment

- Mention any knowledge of molding techniques, such as green sand or investment casting

3. Demonstrate a Strong Work Ethic and Safety Consciousness

Foundry work requires a strong work ethic and adherence to safety protocols. Candidates should emphasize their willingness to work hard and their commitment to safety in the workplace.

- Discuss their attention to detail and ability to follow instructions precisely

- Explain their understanding of the importance of wearing protective gear and following safety procedures

4. Express Interest in Apprenticeship and Learning

Apprenticeships are designed for individuals who are eager to learn and progress in the foundry industry. Candidates should convey their interest in the apprenticeship program and their willingness to learn from experienced molders.

- Inquire about the mentorship opportunities available in the apprenticeship program

- Express enthusiasm for gaining practical experience and expanding their knowledge of foundry techniques

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bench Molder Apprentice role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.