Are you gearing up for a career in Bending Machine Set Up Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bending Machine Set Up Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

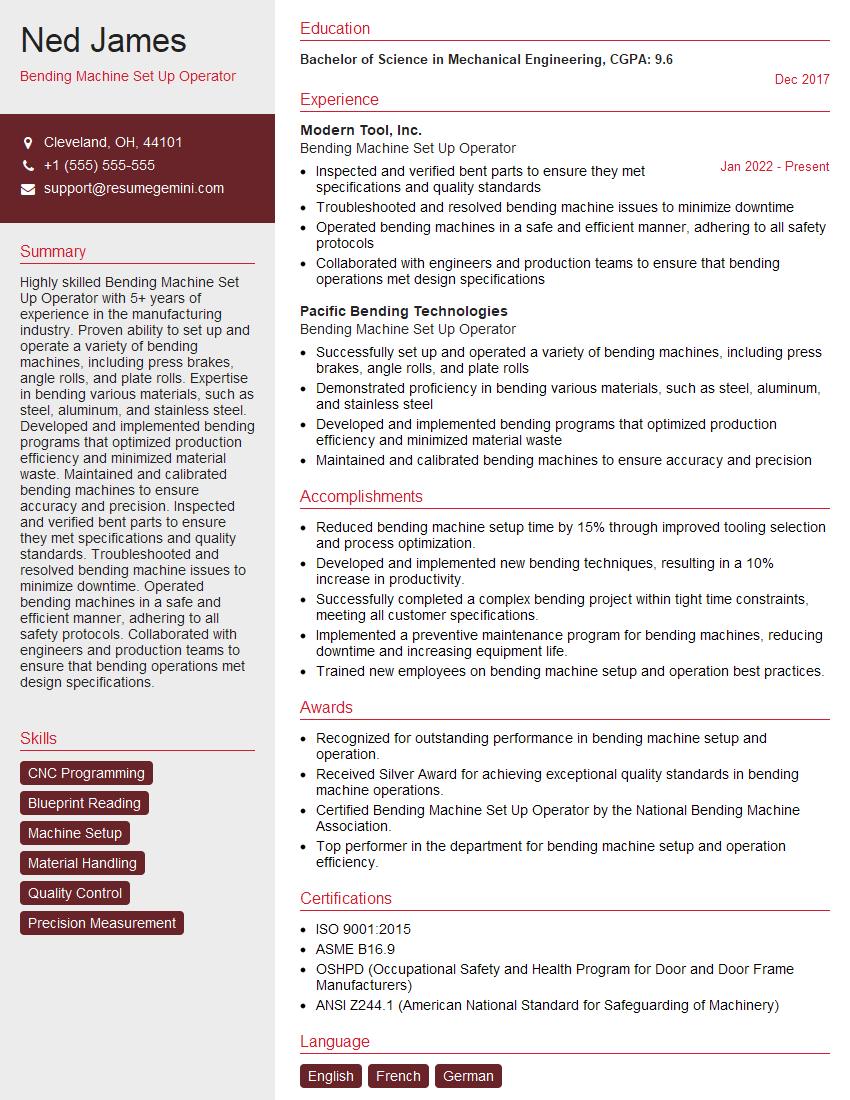

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bending Machine Set Up Operator

1. Describe the main types of bending machines and their applications.

There are three main types of bending machines:

- Press brakes: These machines use a punch and die to bend sheet metal into a desired shape. They are typically used for high-volume production of small to medium-sized parts.

- Roll bending machines: These machines use a series of rolls to bend sheet metal into a cylindrical or conical shape. They are typically used for bending large or thick metal sheets.

- Angle bending machines: These machines use a rotating table to bend sheet metal into an angle. They are typically used for bending small to medium-sized parts at a specific angle.

2. How do you determine the correct tooling for a bending machine?

The correct tooling for a bending machine is determined by the following factors:

- The thickness of the sheet metal being bent

- The type of bend being made

- The desired radius of the bend

Once these factors have been determined, the following steps can be taken to select the correct tooling:

- Refer to the machine manufacturer’s recommendations

- Consult with a tooling supplier

- Experiment with different tooling options to find the best results

3. What are the common problems that can occur during bending operations and how do you troubleshoot them?

Some of the common problems that can occur during bending operations include:

- Springback: This is the tendency of the metal to spring back to its original shape after being bent. It can be minimized by using the correct tooling and bending technique.

- Cracking: This can occur if the metal is bent too sharply. It can be prevented by using the correct tooling and bending technique.

- Tearing: This can occur if the metal is too thick or if the tooling is too sharp. It can be prevented by using the correct tooling and bending technique.

4. How do you maintain and calibrate a bending machine?

A bending machine should be maintained and calibrated regularly to ensure that it is operating at peak performance. Some of the maintenance tasks that should be performed include:

- Cleaning the machine

- Lubricating the moving parts

- Inspecting the tooling

- Calibrating the machine

The calibration procedure will vary depending on the type of bending machine. However, some general steps that can be followed include:

- Zeroing the machine

- Bending a test piece

- Measuring the bend angle

- Adjusting the machine settings accordingly

5. How do you ensure the safety of yourself and others while operating a bending machine?

The following precautions should be taken to ensure the safety of yourself and others while operating a bending machine:

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Keep your hands and other body parts away from the moving parts of the machine.

- Be aware of your surroundings and be sure that there are no other people or objects in the way of the machine.

- Never operate the machine if you are tired or under the influence of alcohol or drugs.

6. What are the different types of materials that can be bent on a bending machine?

A bending machine can be used to bend a variety of materials, including:

- Sheet metal

- Plate

- Tube

- Pipe

7. What are the key factors that affect the bend quality of a bending machine?

The key factors that affect the bend quality of a bending machine include:

- The type of material being bent

- The thickness of the material being bent

- The radius of the bend

- The tooling being used

- The machine settings

8. What is the difference between a bottom bend and a top bend?

A bottom bend is a bend that is made with the material resting on the bottom die. A top bend is a bend that is made with the material resting on the top die.

- Bottom bends are typically used for bending thin materials.

- Top bends are typically used for bending thick materials.

9. What is the purpose of a back gauge?

A back gauge is a device that is used to control the distance between the bend line and the back of the material.

- Back gauges are typically used to ensure that the bends are made to the correct length.

- They can also be used to create bends that are parallel to each other.

10. What is the difference between a CNC bending machine and a manual bending machine?

A CNC bending machine is a bending machine that is controlled by a computer. A manual bending machine is a bending machine that is operated by hand.

- CNC bending machines are more accurate and efficient than manual bending machines.

- They can also be used to create more complex bends.

- Manual bending machines are less expensive than CNC bending machines.

- They are also easier to operate.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bending Machine Set Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bending Machine Set Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bending Machine Set Up Operators are responsible for setting up and operating a variety of bending machines. They ensure that the machines are properly calibrated and maintained to produce accurate and consistent bends. They may also be responsible for loading and unloading materials, and for checking the quality of the finished product.

1. Setting Up Machines

Bending Machine Set Up Operators set up bending machines according to the specifications of the job. They may use a variety of tools, including wrenches, screwdrivers, and hammers. They must be able to read and understand blueprints and other technical documents.

- Calibrate bending machines according to manufacturer’s specifications

- Install and adjust tooling

- Load and unload materials

2. Operating Machines

Bending Machine Set Up Operators operate bending machines to produce a variety of bends in metal, plastic, and other materials. They must be able to control the speed and pressure of the machine, and to ensure that the bends are accurate and consistent.

- Select and install appropriate tooling for the job

- Set up and operate bending machines

- Monitor the bending process and make adjustments as needed

3. Inspecting Products

Bending Machine Set Up Operators inspect the finished products to ensure that they meet the required specifications. They may use a variety of tools, including calipers, micrometers, and gauges. They must be able to identify and correct any defects.

- Inspect finished products for accuracy and quality

- Identify and correct defects

- Maintain a clean and organized work area

4. Troubleshooting

Bending Machine Set Up Operators troubleshoot and repair bending machines. They may use a variety of tools, including wrenches, screwdrivers, and electrical testers. They must be able to identify and correct a variety of problems.

- Troubleshoot and repair bending machines

- Identify and correct electrical and mechanical problems

- Maintain a safe and efficient work environment

Interview Tips

To ace the interview for a Bending Machine Set Up Operator position, it is important to prepare in advance. Here are a few tips:

1. Research the Company

Before the interview, take some time to research the company. This will help you understand the company’s culture and values. You should also research the specific job you are applying for so that you can tailor your answers to the interviewer’s questions.

2. Practice Your Answers

Once you have researched the company and the job, practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for the interview. This means wearing a suit or business casual attire.

4. Be Polite and Respectful

Be polite and respectful to the interviewer and everyone else you meet during the interview process. This includes the receptionist, security guards, and other employees.

5. Follow Up

After the interview, send a thank-you note to the interviewer. This will show your appreciation for their time and consideration.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bending Machine Set Up Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.