Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bending Shed Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bending Shed Worker so you can tailor your answers to impress potential employers.

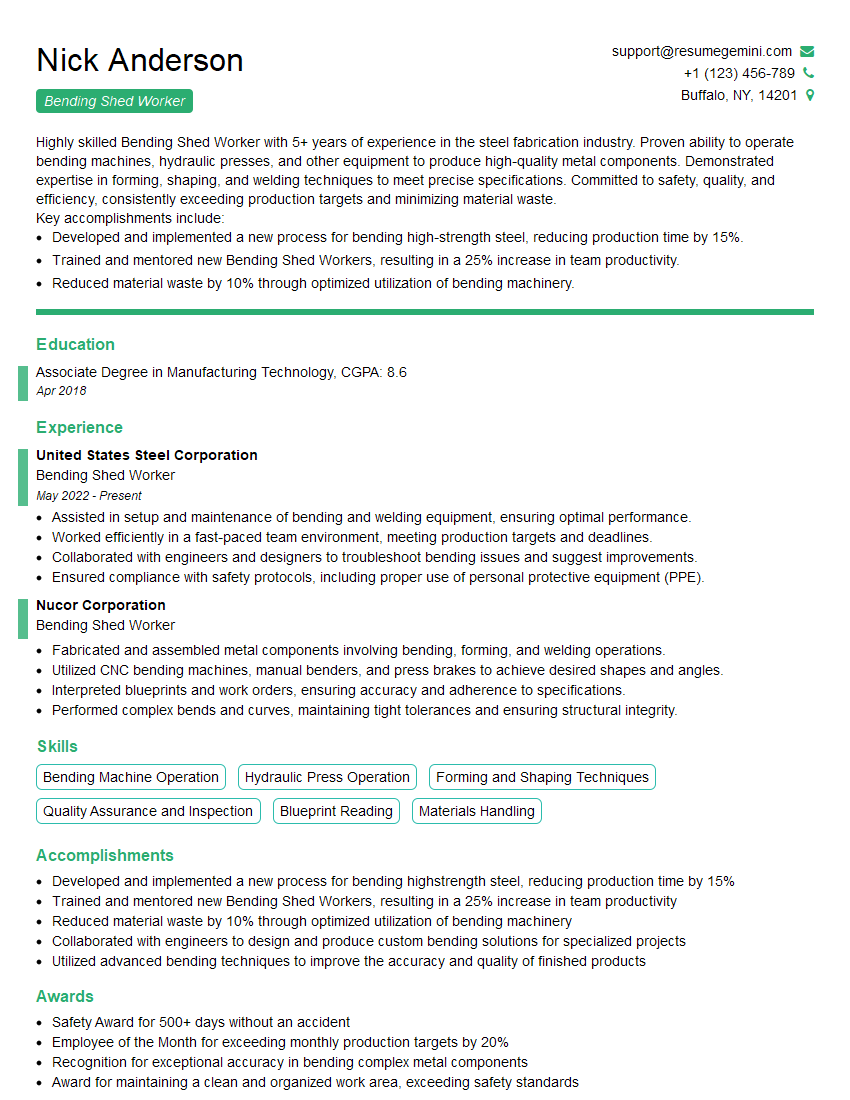

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bending Shed Worker

1. What are the essential steps involved in tube bending?

- Set up the bending machine

- Calculate the bending radius and angle

- Mark the bending point on the tube

- Insert the tube into the bending machine and secure it

- Apply pressure and bend the tube to the desired angle

2. What are the different types of tube benders and their applications?

Hydraulic benders

- Use hydraulic pressure to bend tubes

- Suitable for bending large-diameter tubes

- Offer high precision and bending force

Mechanical benders

- Use mechanical force to bend tubes

- Suitable for bending small-diameter tubes

- Offer high speed and accuracy

3. How do you ensure the quality of the bent tubes?

- Inspect the tubes before and after bending

- Check for any cracks, distortions, or damage

- Measure the bending radius and angle to ensure accuracy

- Calibrate the bending machine regularly

4. What are the common challenges in tube bending and how do you overcome them?

- Wrinkling: Use a larger bending radius

- Deformation: Use a mandrel or internal support

- Springback: Apply counter-bending force

- Incorrect bending angle: Check the machine calibration and setup

5. What are the safety precautions you must follow while operating a tube bender?

- Wear appropriate PPE (gloves, safety glasses, etc.)

- Operate the machine only when trained and authorized

- Secure the tube firmly before bending

- Avoid working near the bending point

- Report any equipment malfunctions or safety concerns immediately

6. Describe the process of bending a tube using a CNC bending machine.

- Program the machine with the desired bending parameters

- Load the tube into the machine

- Initiate the bending process

- Monitor the machine’s progress

- Inspect the bent tube for accuracy and quality

7. What are the advantages of using a CNC bending machine over a manual bender?

- Higher precision and accuracy

- Faster bending speed

- Reduced labor costs

- Less material waste

- Increased production capacity

8. Explain the importance of proper tooling selection in tube bending.

- Correct tool selection ensures optimal bending results

- Matching the tool size to the tube diameter and thickness

- Using the right type of mandrel for internal support

- Proper tool maintenance extends tool life

9. Describe any experience you have troubleshooting tube bending issues.

- Identify the issue through inspection and observation

- Check the machine settings and recalibrate if necessary

- Examine the tooling for wear or damage

- Adjust the bending parameters to optimize performance

10. What motivates you to achieve the best results in tube bending?

- Pride in delivering high-quality work

- Desire to contribute to the success of the team

- Continuous improvement and learning

- Meeting and exceeding customer expectations

- Passion for precision and accuracy

11. How do you stay up-to-date with the latest advancements in tube bending technology?

- Attend industry conferences and exhibitions

- Read technical journals and articles

- Network with peers and experts

- Participate in training and development programs

- Collaborate with suppliers and manufacturers

12. What role do you believe quality control plays in the tube bending process?

- Ensuring compliance with industry standards

- Maintaining high levels of accuracy and precision

- Identifying and correcting potential defects

- Monitoring production processes and making adjustments as needed

- Building customer confidence and trust

13. How do you handle the production of complex and intricate tube bends?

- Carefully studying the design specifications

- Utilizing advanced bending techniques and specialized tooling

- Performing multiple bending operations with precision

- Employing specialized software for simulations and calculations

- Collaborating with engineers and designers for optimal solutions

14. What strategies do you employ to optimize tube bending and minimize scrap?

- Proper selection of tooling and bending parameters

- Effective use of mandrels and other support systems

- Careful handling of tubes to prevent damage

- Regular calibration and maintenance of bending equipment

- Implementation of quality control measures throughout the process

15. How do you ensure that bent tubes meet the specified dimensional and geometrical requirements?

- Utilizing precision measuring tools and inspection equipment

- Adhering to strict quality control procedures

- Employing statistical process control techniques

- Performing dimensional checks at various stages of the production process

- Seeking feedback from customers to enhance accuracy and meet their specific requirements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bending Shed Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bending Shed Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Bending Shed Worker is responsible for bending and shaping metal materials, ensuring the accuracy and precision of the finished products. Here are the key responsibilities associated with this role:

1. Bending and Shaping Metal

Using bending machines, the worker operates them to bend and shape metal materials according to the required specifications.

- Selects the appropriate bending machine and tooling for the job.

- Adjusts machine settings, including bend angle, pressure, and speed.

2. Fabricating Metal Components

The worker constructs and assembles metal components using bending and welding techniques.

- Interprets blueprints and specifications to fabricate metal parts and structures.

- Welds metal components together using appropriate welding methods.

3. Quality Inspection

The worker conducts quality checks to ensure the accuracy and precision of the finished products.

- Inspects bent and shaped metal parts for accuracy, dimensions, and surface finish.

- Identifies and rectifies any defects.

4. Machine Maintenance

The worker maintains and performs minor repairs on bending machines and other equipment.

- Lubricates and cleans bending machines to maintain their optimal performance.

- Reports any major equipment issues to the supervisor.

Interview Tips

1. Research the Company and Industry

Familiarize yourself with the company’s profile, size, products/services, and industry trends. This will help you understand the company’s business and the role’s relevance within the industry.

- Visit the company website and social media pages.

- Read industry news and articles to stay informed about the latest advancements.

2. Practice Your Answers

Anticipate common interview questions and prepare concise, well-structured answers. Practice delivering your answers confidently and clearly.

- Consider questions related to your bending skills, experience with bending machines, and quality control measures.

- Prepare examples to support your answers and demonstrate your problem-solving abilities.

3. Highlight Transferable Skills

If you don’t have direct bending shed experience, focus on transferable skills that are relevant to the job, such as manual dexterity, attention to detail, and mechanical aptitude.

- Emphasize your experience in other manufacturing or production roles.

- Highlight your ability to work in a fast-paced environment and troubleshoot problems.

4. Ask Thoughtful Questions

Asking relevant questions at the end of the interview shows your interest in the role and the company. Prepare questions that demonstrate your enthusiasm and curiosity.

- Inquire about the company’s training and development opportunities.

- Ask about the company’s safety protocols and industry certifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bending Shed Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.