Feeling lost in a sea of interview questions? Landed that dream interview for Benzol Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Benzol Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

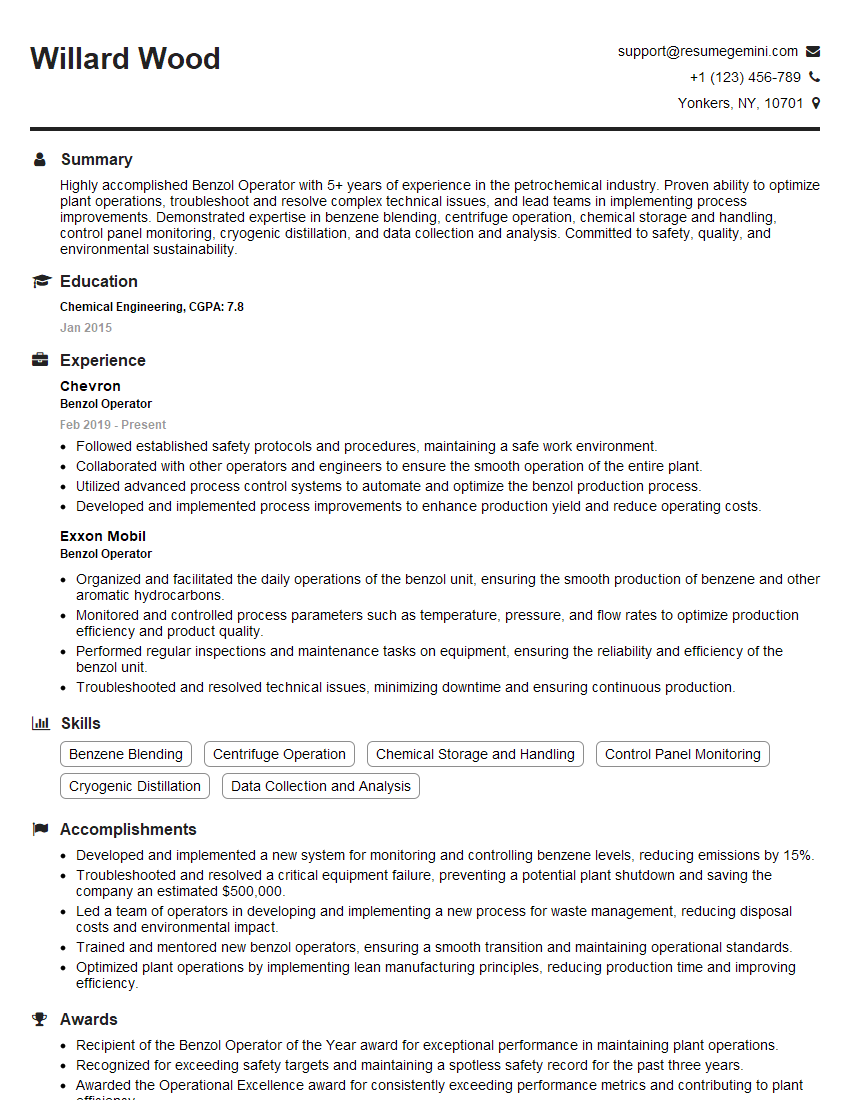

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Benzol Operator

1. What are the key responsibilities of a Benzol Operator?

- Operate and monitor the benzol plant, including all equipment and processes.

- Conduct routine inspections and maintenance of the plant and equipment.

- Troubleshoot and resolve any problems that arise during the operation of the plant.

- Ensure that the plant is operating safely and efficiently.

- Maintain accurate records of all plant operations and maintenance activities.

2. What are the different types of benzol plants?

- There are two main types of benzol plants: batch plants and continuous plants.

- Batch plants are used to produce small quantities of benzol, while continuous plants are used to produce large quantities of benzol.

- Batch plants are typically used in situations where the demand for benzol is low, while continuous plants are used in situations where the demand for benzol is high.

3. What are the raw materials used in the production of benzol?

- The main raw material used in the production of benzol is benzene.

- Benzene is typically obtained from the distillation of crude oil.

- Other raw materials used in the production of benzol include water, steam, and catalysts.

4. What are the different steps involved in the production of benzol?

- The first step in the production of benzol is the distillation of crude oil.

- This process separates the benzene from the other components of the crude oil.

- The benzene is then reacted with water and steam in a reaction vessel.

- This reaction produces benzol and hydrogen gas.

- The benzol is then separated from the hydrogen gas and purified.

5. What are the different uses of benzol?

- Benzol is used in the production of a variety of chemicals, including benzene, toluene, and xylene.

- These chemicals are used in the production of a wide range of products, including plastics, dyes, and pharmaceuticals.

- Benzol is also used as a solvent and a fuel.

6. What are the safety hazards associated with the production of benzol?

- The production of benzol can be hazardous due to the use of flammable and toxic chemicals.

- Benzene is a known carcinogen, and it can cause a variety of health problems, including cancer, birth defects, and neurological damage.

- It is important to take precautions to protect workers from exposure to benzene and other hazardous chemicals.

7. What are the environmental impacts of the production of benzol?

- The production of benzol can have a negative impact on the environment.

- The release of benzene and other hazardous chemicals into the environment can contaminate air, water, and soil.

- This contamination can harm wildlife and human health.

- It is important to take steps to reduce the environmental impact of the production of benzol.

8. What are the current trends in the benzol industry?

- The benzol industry is currently facing a number of challenges, including the rising cost of raw materials and the increasing demand for more environmentally friendly products.

- The industry is also facing competition from new technologies, such as the use of renewable energy sources.

- Despite these challenges, the benzol industry is expected to continue to grow in the coming years.

9. What are the future prospects for the benzol industry?

- The future prospects for the benzol industry are positive.

- The demand for benzol is expected to continue to grow in the coming years, and the industry is expected to benefit from the development of new technologies.

- The industry is also expected to benefit from the increasing demand for more environmentally friendly products.

10. What are the key challenges facing the benzol industry?

- The benzol industry is facing a number of challenges, including the rising cost of raw materials, the increasing demand for more environmentally friendly products, and competition from new technologies.

- The industry is also facing challenges related to the safe and responsible production of benzol.

- Despite these challenges, the benzol industry is expected to continue to grow in the coming years.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Benzol Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Benzol Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Benzol Operator plays a crucial role in the smooth operation of a petrochemical plant by monitoring and controlling various processes related to the production, recovery, and handling of benzene and its derivatives.

1. Process Monitoring and Control

Continuously monitors and controls the production process, including raw material feed, reaction conditions, and product quality, to ensure efficient and safe operation.

- Observes and analyzes process parameters, such as temperature, pressure, flow rates, and composition, to maintain optimal conditions.

- Adjusts process parameters and equipment settings to optimize yield, minimize waste, and prevent deviations from specifications.

2. Equipment Operation and Maintenance

Operates and maintains plant equipment, including pumps, valves, pipelines, reactors, and distillation columns, to ensure their proper functioning.

- Performs routine maintenance tasks, such as cleaning, lubrication, and inspections, to ensure equipment reliability and prevent breakdowns.

- Troubleshoots and resolves equipment malfunctions promptly to minimize downtime and maintain production efficiency.

3. Quality Control and Analysis

Conducts quality control tests on raw materials, intermediates, and finished products to ensure compliance with specifications.

- Analyzes samples using laboratory equipment to determine their physical and chemical properties.

- Interprets test results and takes corrective actions to maintain product quality and prevent contamination.

4. Safety and Emergency Response

Adheres to established safety protocols and procedures to prevent accidents and ensure the well-being of personnel and the environment.

- Monitors and controls hazardous materials, such as benzene, to minimize risks and comply with environmental regulations.

- Responds to emergencies promptly and effectively to mitigate potential hazards.

Interview Tips

To prepare effectively for your Benzol Operator interview, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the petrochemical industry, the company’s operations, and their specific processes related to benzene production.

- Visit the company’s website, read industry publications, and conduct online research to gain insights into their business.

- Demonstrate your understanding of the benzene production process and its importance in the industry.

2. Practice Your Technical Skills

Review your knowledge of process monitoring, equipment operation, and quality control techniques.

- Prepare to discuss specific examples of how you have monitored and controlled chemical processes.

- Describe your experience with operating and maintaining industrial equipment, including troubleshooting and repair.

3. Highlight Your Safety and Environmental Awareness

Emphasize your understanding of safety protocols and your commitment to environmental protection.

- Provide examples of how you have ensured the safe handling and storage of hazardous materials.

- Explain how you have contributed to environmental compliance and pollution prevention initiatives.

4. Prepare for Common Interview Questions

Anticipate questions about your experience, technical abilities, and problem-solving skills.

- Be ready to describe a time when you successfully resolved a plant malfunction.

- Discuss your approach to maintaining product quality standards.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Benzol Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.