Feeling lost in a sea of interview questions? Landed that dream interview for Benzol Still Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Benzol Still Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

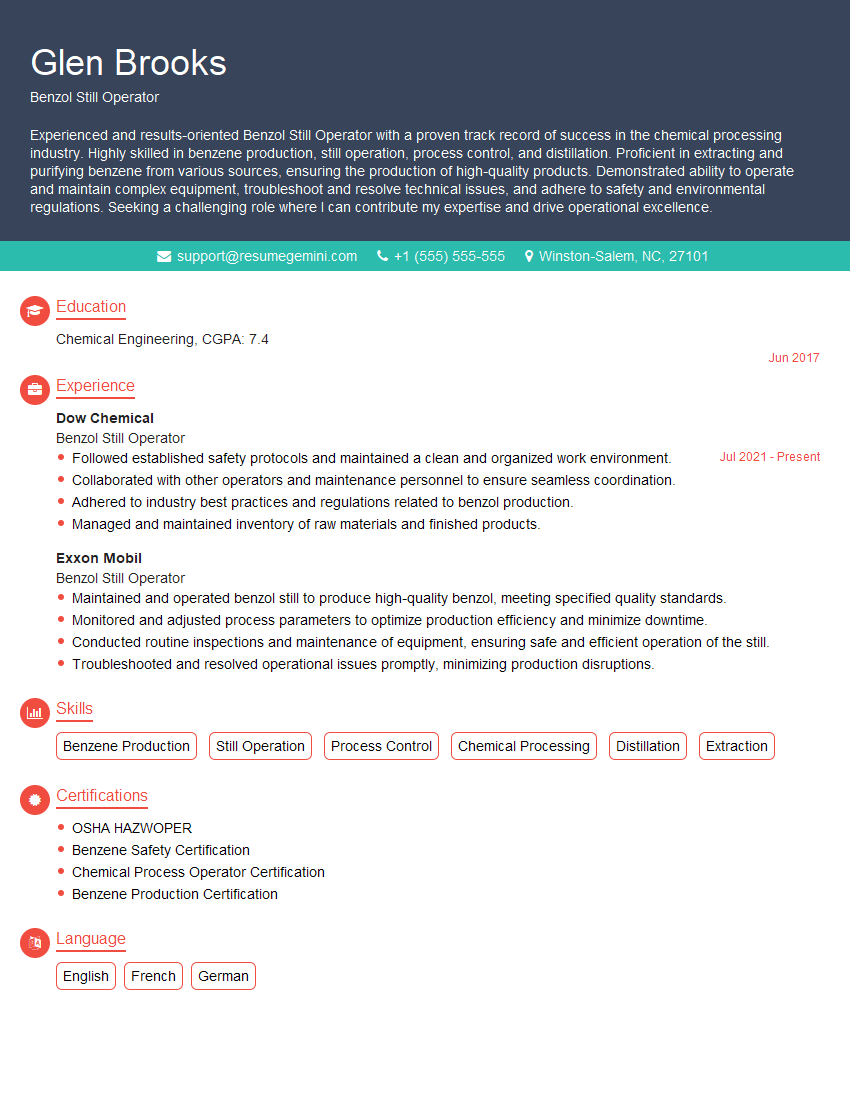

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Benzol Still Operator

1. Explain the process of distillation in a benzol still?

Distillation in a benzol still is a separation process used to separate benzol from other hydrocarbons and impurities. The process involves heating the benzol-containing mixture to its boiling point, and then condensing the vapors to collect the purified benzol.

- The benzol-containing mixture is heated in a still pot, which is a heated vessel.

- As the mixture heats up, the benzol vaporizes and rises to the top of the still pot.

- The benzol vapor travels through a condenser, which cools the vapor and condenses it back into a liquid.

- The condensed benzol is collected in a receiver.

2. Describe the role of a reboiler in a benzol still?

A reboiler is a heat exchanger that is used to provide heat to the bottom of a distillation column. In a benzol still, the reboiler is used to provide heat to the bottom of the column, which helps to vaporize the benzol and other light hydrocarbons.

- The reboiler is heated by a heating medium, such as steam or hot water.

- The heating medium flows through the reboiler tubes, and the heat is transferred to the benzol mixture in the column.

- The heat from the reboiler helps to vaporize the benzol and other light hydrocarbons, which rise to the top of the column.

3. What are the key operating parameters that need to be monitored and controlled in a benzol still?

The key operating parameters that need to be monitored and controlled in a benzol still include:

- Temperature

- Pressure

- Flow rate

- Composition

4. What are the different types of instrumentation used in a benzol still?

The different types of instrumentation used in a benzol still include:

- Temperature sensors

- Pressure sensors

- Flow meters

- Composition analyzers

5. What are the potential hazards associated with operating a benzol still?

The potential hazards associated with operating a benzol still include:

- Fire

- Explosion

- Benzene exposure

- Other chemical hazards

6. What are the safety precautions that need to be taken when operating a benzol still?

The safety precautions that need to be taken when operating a benzol still include:

- Proper training

- Use of personal protective equipment

- Following safe operating procedures

- Maintaining the still in good working order

7. Describe the startup procedure for a benzol still?

The startup procedure for a benzol still typically involves the following steps:

- Check the still for any damage or leaks.

- Fill the still with the benzol-containing mixture.

- Start the heating medium and slowly raise the temperature.

- Monitor the temperature and pressure of the still.

8. Describe the shutdown procedure for a benzol still?

The shutdown procedure for a benzol still typically involves the following steps:

- Stop the heating medium.

- Allow the still to cool down.

- Drain the benzol from the still.

- Clean the still.

9. What are the common troubleshooting problems that can occur with a benzol still?

Some common troubleshooting problems that can occur with a benzol still include:

- Leaking still

- Overheating

- Plugging

- Corrosion

10. What are the key maintenance tasks that need to be performed on a benzol still?

The key maintenance tasks that need to be performed on a benzol still include:

- Regular inspections

- Cleaning

- Repairs

- Calibration

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Benzol Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Benzol Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Benzol Still Operators are responsible for operating and monitoring the distillation process in a chemical plant to separate benzene from other hydrocarbons. Their primary goal is to ensure the efficient and safe production of benzene while adhering to quality standards and environmental regulations.

1. Monitoring and Controlling Distillation Process

Operate and monitor the distillation equipment, including stills, columns, condensers, and pumps, to separate benzene from other hydrocarbons.

- Adjust process parameters such as temperature, pressure, and flow rates to optimize benzene yield and purity.

- Monitor and maintain equipment performance to ensure efficient operation and prevent breakdowns.

2. Quality Control and Analysis

Conduct quality control tests on benzene and other products to ensure compliance with specifications.

- Analyze samples using laboratory equipment and techniques, such as gas chromatography and spectrophotometry.

- Document test results and take corrective actions as needed to maintain product quality.

3. Maintenance and Troubleshooting

Perform routine maintenance and repairs on distillation equipment and related systems.

- Identify and troubleshoot equipment malfunctions, using technical knowledge and problem-solving skills.

- Coordinate with maintenance personnel to resolve complex issues and ensure safe operation.

4. Safety and Environmental Compliance

Follow all safety protocols and hazardous materials handling procedures.

- Monitor and maintain a safe work environment, including proper ventilation and handling of flammable materials.

- Comply with environmental regulations and waste disposal procedures to minimize environmental impact.

Interview Tips

Preparing for a Benzol Still Operator interview requires a combination of technical knowledge, industry experience, and interview skills. Here are some tips to help you ace the interview:

1. Research the Industry and Company

Familiarize yourself with the benzene distillation process, typical equipment used, and industry best practices.

- Research the specific company you are applying to, including their products, processes, and values.

- This knowledge will demonstrate your interest in the role and the company.

2. Highlight Your Technical Skills

Emphasize your experience and knowledge in operating and monitoring distillation equipment.

- Quantify your achievements by providing specific examples of how you contributed to process efficiency or quality improvements.

- Be prepared to discuss your troubleshooting and problem-solving abilities.

3. Showcase Safety and Compliance Awareness

Stress your adherence to safety protocols and environmental regulations.

- Discuss your understanding of the potential hazards associated with benzene distillation.

- Explain how you ensure a safe and environmentally responsible work environment.

4. Prepare for Commonly Asked Questions

Anticipate questions about your experience with specific distillation equipment, your handling of process deviations, and your commitment to continuous learning.

- Practice answering these questions using the STAR method (Situation, Task, Action, Result).

- This will help you provide structured and compelling responses.

5. Dress Professionally and Arrive Punctually

First impressions matter, so dress professionally and arrive for the interview on time.

- This shows respect for the interviewer and the company.

- It also indicates your attention to detail and punctuality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Benzol Still Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!