Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bevel Face Stoner and Polisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

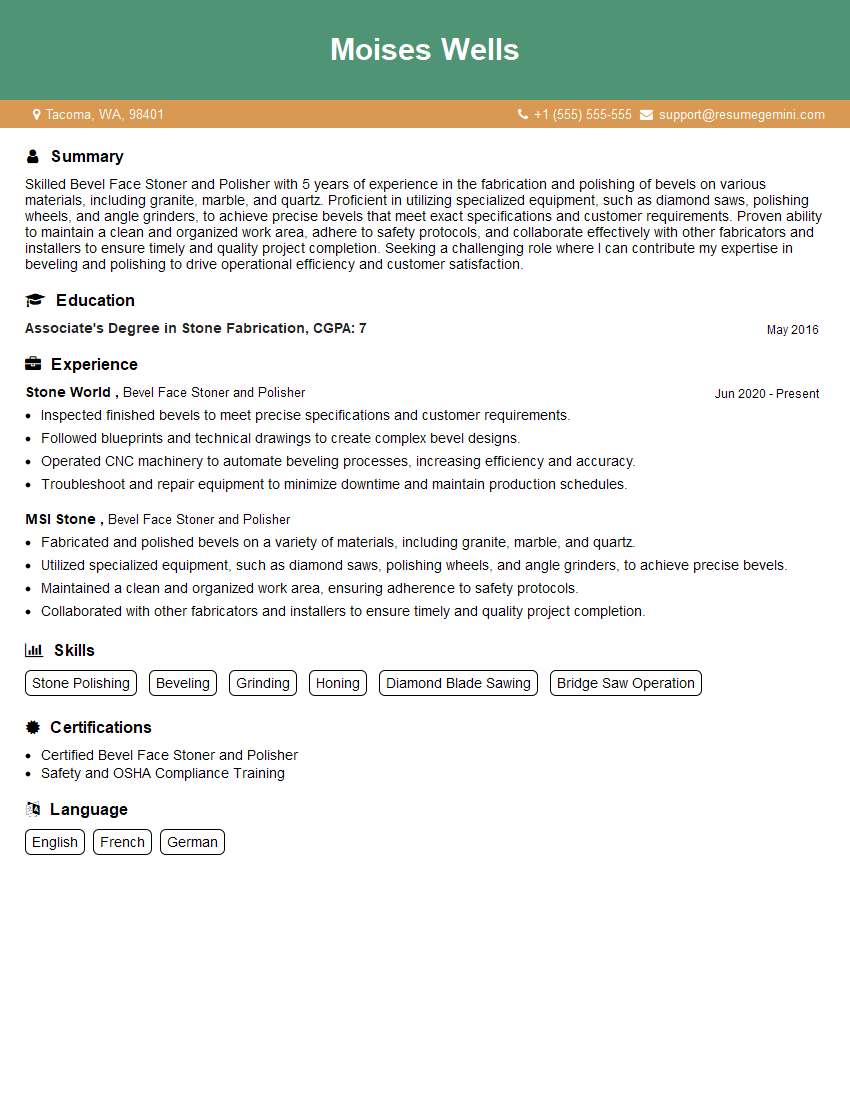

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bevel Face Stoner and Polisher

1. Describe the key principles and processes involved in bevel face stoning and polishing?

Answer:

- Bevel face stoning and polishing involves shaping and finishing the edge of a workpiece to achieve a specific angle and surface finish.

- The process begins with selecting the appropriate abrasive stone and polishing wheel.

- The workpiece is secured in a fixture or jig that holds it at the desired angle.

- The stone or wheel is then brought into contact with the workpiece and moved back and forth across the edge.

- The abrasive action of the stone or wheel removes material and creates the desired bevel.

- The polishing process follows stoning, using finer abrasives to refine the surface finish and remove any remaining burrs or imperfections.

2. Explain the different types of bevels and when each type is typically used?

Answer:

Types of Bevels

- Single Bevel: Sloping away from one side of the workpiece, creating a sharp edge.

- Double Bevel: Sloping away from both sides of the workpiece, creating a thinner, pointed edge.

- Compound Bevel: Combining a single and double bevel, creating a more complex edge.

- Chamfer: A beveled edge with a straight cut across the corner, creating a less sharp angle.

Typical Uses

- Single Bevel: Cutting tools, knives, and scrapers.

- Double Bevel: Precision tools, such as chisels and drills.

- Compound Bevel: Decorative edges, moldings, and fine woodworking.

- Chamfer: Removing sharp corners for safety or aesthetic purposes.

3. What factors influence the choice of stone or wheel for bevel face stoning and polishing?

Answer:

- Material of the workpiece: Different materials require specific abrasives to achieve the desired results.

- Hardness of the workpiece: Harder materials require more aggressive abrasives.

- Desired surface finish: Finer abrasives produce smoother finishes.

- Shape and size of the bevel: Smaller or more complex bevels may require specialized stones or wheels.

- Production requirements: High-volume applications may require more durable or efficient abrasives.

4. How do you determine the correct speed and pressure to apply during bevel face stoning and polishing?

Answer:

- Speed: Higher speeds generally remove material faster but can also lead to chatter and burning.

- Pressure: Excessive pressure can cause damage to the workpiece or wheel.

- Workpiece material: Soft materials require lighter pressure and slower speeds.

- Bevel angle: Smaller angles require higher pressure and slower speeds.

- Desired finish: Finer finishes require lower pressure and higher speeds.

5. What are the common defects that can occur during bevel face stoning and polishing, and how do you prevent them?

Answer:

Common Defects

- Chatter: Vibrations that cause uneven surface finish.

- Burning: Discoloration or damage caused by excessive friction.

- Cracking: Occurs in brittle materials due to excessive pressure or thermal stress.

- Loading: Abrasives become clogged with material, reducing cutting efficiency.

Prevention Measures

- Maintain proper speed and pressure.

- Use sharp and clean abrasives.

- Cool the workpiece to prevent thermal stress.

- Lubricate the cutting area to reduce friction.

- Dress the wheel regularly to remove loaded material.

6. Describe the different methods for measuring and inspecting the quality of bevel face stoning and polishing?

Answer:

- Visual inspection: Examine the surface for defects, such as chatter or burning.

- Micrometer: Measure the angle and width of the bevel.

- Profilometer: Measure the surface roughness and finish.

- Coordinate measuring machine (CMM): Create a detailed 3D model of the bevel for precise analysis.

7. What safety precautions are essential when operating bevel face stoning and polishing equipment?

Answer:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Ensure the equipment is properly grounded and maintained.

- Never operate the equipment without guards or safety shields in place.

- Use sharp and clean abrasives to minimize dust and debris.

- Ventilate the work area to remove dust and fumes.

8. What are the key quality control parameters for bevel face stoning and polishing?

Answer:

- Angle and width of the bevel: Must meet specified tolerances.

- Surface finish: Must meet the desired roughness and texture requirements.

- Absence of defects: No chatter, burning, cracking, or loading.

- Dimensional accuracy: The bevel must conform to the specified dimensions.

9. Describe the maintenance procedures for bevel face stoning and polishing equipment?

Answer:

- Clean and lubricate all moving parts regularly.

- Dress the polishing wheel to restore its shape and efficiency.

- Replace worn or damaged abrasives.

- Inspect the equipment for any signs of wear or damage.

- Calibrate the equipment regularly to ensure accuracy.

10. How do you stay up-to-date with the latest techniques and advancements in bevel face stoning and polishing?

Answer:

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Consult with equipment manufacturers and experts.

- Seek training and certification programs.

- Experiment with new techniques and materials to improve results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bevel Face Stoner and Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bevel Face Stoner and Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Bevel Face Stoner and Polisher is responsible for shaping, finishing, and polishing stone surfaces using various tools and techniques. Their work requires precision, attention to detail, and a deep understanding of stoneworking principles.

1. Stone Preparation

Preparing stone surfaces for stoning and polishing, including cleaning, rough-surfacing, and setting up the stone for processing.

- Inspecting stone surfaces for defects, cracks, or imperfections.

- Cleaning stone surfaces to remove dirt, debris, or other contaminants.

- Rough-surfacing the stone to provide a uniform surface for stoning.

- Setting up the stone securely for processing, ensuring its stability during stoning and polishing.

2. Stoning and Polishing

Performing stoning and polishing operations on stone surfaces using appropriate tools and techniques.

- Selecting and using appropriate stoning and polishing tools and abrasives.

- Applying stoning and polishing techniques to achieve the desired surface finish.

- Monitoring the stoning and polishing process to ensure accuracy and quality.

- Making necessary adjustments to stoning and polishing parameters to achieve optimal results.

3. Surface Finishing

Finishing the processed stone surfaces to achieve the desired appearance and texture.

- Applying sealers, coatings, or other treatments to protect and enhance the stone surface.

- Inspecting finished stone surfaces for quality and compliance with specifications.

- Making necessary adjustments or repairs to ensure the finished stone surface meets the required standards.

- Polishing the stone surface to achieve a high-gloss finish, if required.

4. Equipment Maintenance

Performing basic maintenance and troubleshooting on stoning and polishing equipment.

- Cleaning and lubricating stoning and polishing tools and equipment.

- Inspecting equipment for wear, damage, or malfunctions.

- Troubleshooting and resolving minor equipment issues to maintain optimal performance.

- Reporting any major equipment issues or maintenance needs to supervisors.

Interview Tips

Preparing for an interview as a Bevel Face Stoner and Polisher requires a well-rounded approach. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the company and the stoneworking industry. This will give you a deeper understanding of the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website and social media pages to learn about their history, products, services, and recent news.

- Read industry publications and articles to stay updated on the latest trends and best practices in stoneworking.

- Attend industry events or connect with professionals in the field to expand your knowledge and network.

2. Practice Your Skills and Knowledge

As a Bevel Face Stoner and Polisher, it’s essential to demonstrate your proficiency in stoning and polishing techniques. Practice your skills before the interview so that you can confidently showcase your abilities.

- Work on sample stone pieces to practice different stoning and polishing techniques.

- Familiarize yourself with the different types of stones and their specific characteristics.

- Research and practice using various stoning and polishing tools and equipment.

- Seek feedback from experienced stoneworkers or mentors to improve your skills and knowledge.

3. Prepare for Common Interview Questions

During the interview, you will likely be asked a range of questions related to your skills, experience, and qualifications. Prepare for some of the most common interview questions to ensure you can answer them effectively.

- Tell me about your experience in stoning and polishing stone surfaces.

- What are the different types of stones you have worked with?

- How do you achieve different surface finishes, such as honed, polished, or brushed?

- What are the safety precautions you take when working with stone?

- How do you maintain and troubleshoot stoning and polishing equipment?

4. Showcase Your Passion and Motivation

A genuine passion for stoneworking and a strong desire to produce high-quality results will set you apart in the interview. Express your enthusiasm for the craft and explain why you are drawn to this profession.

- Share examples of projects you have worked on that demonstrate your skills and creativity.

- Explain how you stay updated on new techniques and advancements in the industry.

- Emphasize your attention to detail, commitment to quality, and willingness to learn and grow.

- Highlight your ability to work independently and as part of a team, as required in a stoneworking environment.

Next Step:

Now that you’re armed with the knowledge of Bevel Face Stoner and Polisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bevel Face Stoner and Polisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini