Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bevel Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

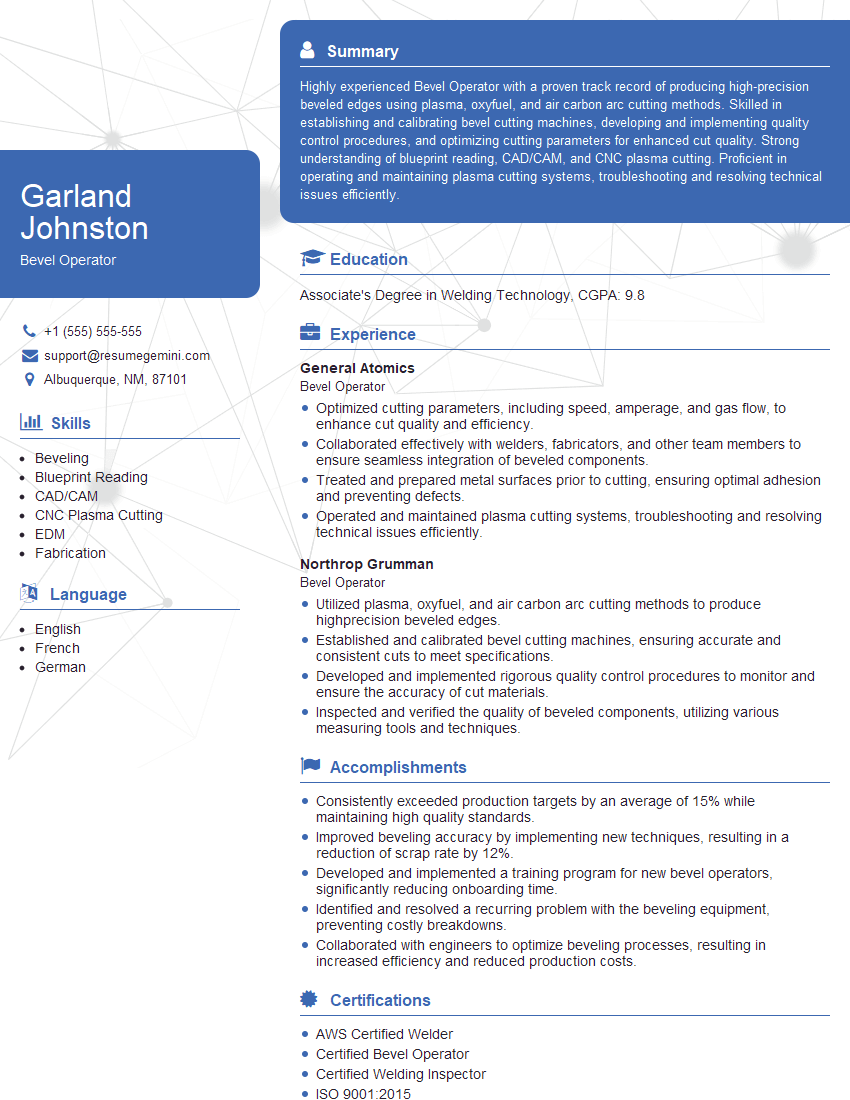

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bevel Operator

1. Explain the safety precautions you take when operating a beveling machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves.

- Securely fasten the machine to a stable surface to prevent movement during operation.

- Inspect the machine before each use for any damage or defects and ensure all guards are in place.

- Never operate the machine while under the influence of drugs or alcohol

- Keep the work area clean and free of debris to prevent tripping or slipping hazards.

2. Describe the different types of bevels you can create with a beveling machine?

of the answer

- Single bevel

- Double bevel

- Compound bevel

- V-bevel

- U-bevel

Subheading of the answer

- Counterbore

- Countersink

- Edge bevel

- Pipe bevel

- Structural bevel

3. How do you determine the correct bevel angle for a given application?

- Refer to the manufacturer’s specifications or industry standards for the recommended bevel angle for the specific material and application.

- Consider the strength and durability requirements of the joint.

- Take into account the thickness and type of material being beveled.

- For critical applications, consult with an engineer or welding expert to determine the optimal bevel angle.

4. What are the common problems that can occur while operating a beveling machine and how do you troubleshoot them?

- Bevel is not smooth or accurate – Check the sharpness of the cutting tool, adjust the feed rate, and ensure the machine is properly calibrated.

- Machine is vibrating excessively – Inspect the machine for loose bolts or damaged components, check the balance of the cutting tool, and ensure the machine is securely fastened to the surface.

- Bevel is not perpendicular to the surface – Adjust the angle setting on the machine and ensure the workpiece is properly clamped.

- Machine is overheating – Allow the machine to cool down, check for proper lubrication, and ensure the ventilation system is functioning.

- Sparks or smoke are produced – Check if the cutting tool is dull or damaged, adjust the cutting speed, and ensure the workpiece is clean and free of any contaminants.

5. How do you maintain and calibrate a beveling machine to ensure optimal performance?

- Regularly clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect the cutting tool for wear or damage and replace as needed.

- Check the alignment of the cutting head and adjust if necessary.

- Calibrate the machine using a precision angle gauge or reference surface to ensure accurate bevel angles.

- Follow the manufacturer’s recommended maintenance schedule for optimal performance and longevity.

6. What are the different factors that can affect the quality of a beveled edge?

- Cutting tool sharpness – A dull or damaged cutting tool can produce rough or inaccurate bevels.

- Cutting speed and feed rate – Too high or too low cutting speeds and feed rates can affect the quality of the bevel.

- Material type – Different materials may require different cutting parameters to achieve the desired bevel quality.

- Machine stability – A machine that is not properly secured or calibrated can produce uneven or inaccurate bevels.

- Operator skill and experience – The skill and experience of the operator can also impact the quality of the beveled edge.

7. How do you inspect a beveled edge to ensure it meets the required specifications?

- Visual inspection – Examine the bevel for any obvious defects, such as unevenness, roughness, or nicks.

- Angle measurement – Use an angle gauge or protractor to measure the bevel angle and ensure it meets the specified tolerance.

- Surface finish measurement – Use a surface roughness tester to measure the surface finish of the bevel and ensure it meets the required smoothness.

- Dimensional measurement – Measure the width and depth of the bevel to ensure it meets the specified dimensions.

- Non-destructive testing (NDT) – For critical applications, NDT methods such as ultrasonic testing or dye penetrant testing can be used to inspect the bevel for any internal defects or cracks.

8. What are the different types of cutting tools used for beveling and what are their advantages and disadvantages?

- Abrasive wheels – Provide a fast cutting rate but can produce a rough surface finish.

- Carbide inserts – Offer a longer tool life and can produce a smoother surface finish, but are more expensive.

- High-speed steel (HSS) cutters – Versatile and affordable, but have a shorter tool life than carbide inserts.

- Diamond-tipped cutters – Provide the highest cutting speed and longest tool life, but are also the most expensive.

- CBN (cubic boron nitride) cutters – Similar to diamond-tipped cutters, but with a longer tool life and can be used on harder materials.

9. How do you select the appropriate cutting parameters (speed, feed, depth of cut) for a given beveling application?

- Consider the material type and thickness.

- Refer to the manufacturer’s recommendations for the cutting tool.

- Start with conservative cutting parameters and gradually increase them until the desired cutting performance is achieved.

- Monitor the cutting process and adjust the parameters as needed to maintain optimal performance and surface finish.

10. Describe your experience in using beveling machines for different applications and the challenges you have encountered.

- Provide specific examples of projects where you used beveling machines.

- Describe the challenges you faced, such as working with difficult materials or achieving precise bevel angles.

- Explain how you overcame these challenges and the techniques you used to ensure successful beveling operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bevel Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bevel Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bevel Operators, also known as Weld Bevelers, are responsible for preparing and cutting metal surfaces for welding operations. They use specialized equipment to create beveled edges on metal pipes, sheets, and plates, ensuring a smooth and precise fit for welding.

1. Setup and Operation of Beveling Equipment

Bevel Operators set up and calibrate beveling machines according to specified blueprints and welding requirements. They adjust settings such as cutting angle, depth, and speed to achieve the desired bevel.

- Operate oxy-fuel, plasma, or laser cutting machines

- Monitor equipment performance and make adjustments as needed

2. Preparation of Metal Surfaces

Before beveling, Bevel Operators clean and prepare metal surfaces to ensure a clean cut. They remove rust, dirt, and any other contaminants that could affect the welding process.

- Grind and smooth metal surfaces as required

- Inspect surfaces for defects or imperfections

3. Accurate Bevel Cutting

Bevel Operators use cutting torches or automated machines to create precise beveled edges. They follow specified dimensions and tolerances to ensure that the bevels align properly for welding.

- Control cutting speed and angle to achieve desired bevel

- Ensure uniformity and consistency in bevel preparation

4. Quality Control and Inspection

Bevel Operators inspect and measure finished bevels to verify that they meet specifications. They use precision measuring tools and gauges to check angles, depths, and surface finish. Any non-conforming bevels are corrected or rejected.

- Conduct visual and dimensional inspections

- Maintain records of bevel dimensions and quality checks

Interview Tips

To ace the Bevel Operator interview, it’s crucial to showcase your technical skills, experience, and attention to detail. Consider the following tips:

1. Research the Company and Job Requirements

Before the interview, thoroughly research the company and the specific Bevel Operator position. This will demonstrate your interest and enthusiasm for the role.

- Review the company website and social media pages

- Identify the key responsibilities and qualifications for the position

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in operating beveling equipment, including oxy-fuel, plasma, or laser machines. Quantify your experience by providing specific examples and metrics.

- Describe your involvement in previous beveling projects

- Mention any certifications or training related to beveling

3. Demonstrate Attention to Detail

Bevel Operators must be meticulous and pay attention to detail. Highlight your ability to follow precise instructions, measure accurately, and maintain high-quality standards.

- Discuss how you ensure the accuracy of your bevels

- Explain your quality control procedures and how you maintain consistency

4. Prepare for Behavioral Questions

Behavioral interviewing questions focus on your past experiences and behaviors. These questions help the interviewer assess your problem-solving, communication, and teamwork skills.

- Use the STAR method to answer behavioral questions (Situation, Task, Action, Result)

- Provide specific examples where you effectively solved problems or worked in a team

Next Step:

Now that you’re armed with the knowledge of Bevel Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bevel Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini