Are you gearing up for an interview for a Bevel Polisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bevel Polisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

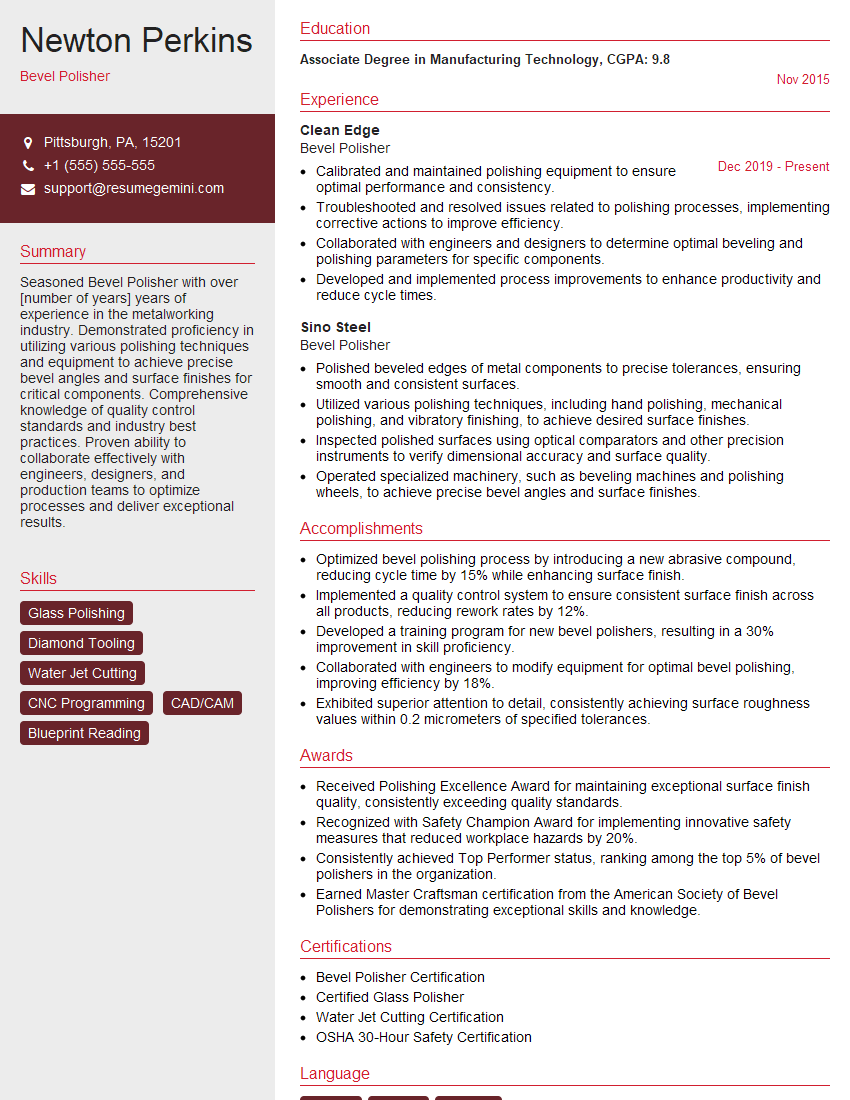

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bevel Polisher

1. What are the different types of bevel polishing machines?

There are various types of bevel polishing machines, including:

- Manual bevel polishing machines: Operated by hand, these machines are ideal for small-scale or intricate polishing jobs.

- Semi-automatic bevel polishing machines: Featuring a motor that drives the polishing wheel, these machines offer increased efficiency and precision.

- CNC bevel polishing machines: Computer-controlled, these machines provide high accuracy and repeatability, suitable for mass production.

2. How do you select the appropriate polishing wheel for a given material?

Material Hardness

- Hard materials like steel or carbide require harder wheels (e.g., vitrified or metal-bonded).

- Soft materials like aluminum or plastics use softer wheels (e.g., resin or rubber-bonded).

Wheel Grit

- Coarse grit wheels (80-120) remove large amounts of material quickly but leave a rougher surface.

- Finer grit wheels (220-600) produce finer finishes with less material removal.

3. What techniques do you use to achieve a mirror finish on a beveled edge?

Achieving a mirror finish requires a multi-step process:

- Rough polishing: Using a coarse-grit wheel to remove excess material and create a smooth base.

- Medium polishing: Using a finer-grit wheel to refine the surface and reduce scratches.

- Fine polishing: Using an extra-fine grit wheel and a polishing compound to remove remaining imperfections.

- Buffing: Using a soft buffing wheel and a polishing compound to create a high-gloss finish.

4. How do you maintain and calibrate a bevel polishing machine?

Maintaining and calibrating the machine ensures optimal performance:

- Cleaning: Regularly clean the machine to remove abrasive dust and debris.

- Wheel Dressing: Periodically dress the polishing wheels to maintain their shape and grit.

- Calibration: Calibrate the machine’s speed, pressure, and angle settings as per manufacturer’s specifications.

- Lubrication: Lubricate moving parts to minimize friction and wear.

5. What safety precautions should be taken when operating a bevel polishing machine?

- Wear appropriate safety gear (gloves, eye protection, hearing protection).

- Securely mount the workpiece to prevent it from flying off.

- Keep hands and loose clothing away from the rotating polishing wheel.

- Ensure proper ventilation to avoid inhaling abrasive dust.

- Follow all manufacturer’s safety instructions and protocols.

6. Can you describe the different types of abrasives used in bevel polishing?

- Natural abrasives: Diamond, garnet, corundum (e.g., emery, ruby, sapphire)

- Synthetic abrasives: Silicon carbide, aluminum oxide, zirconia, cubic boron nitride

- Bonded abrasives: Abrasive particles bonded to a backing material (e.g., vitrified, resin, metal)

- Coated abrasives: Abrasive particles coated onto a flexible backing (e.g., sandpaper, sanding belts)

7. How do you determine the optimal polishing speed and pressure for a particular material?

Material Hardness

- Harder materials require lower speeds and higher pressure to avoid burning.

- Softer materials require higher speeds and lower pressure to prevent excessive removal.

Polishing Wheel Grit

- Coarser grit wheels require higher speeds and pressure to remove more material.

- Finer grit wheels require lower speeds and pressure to achieve a finer finish.

8. What is the purpose of using a honing solution in bevel polishing?

- Lubricates the polishing wheel and reduces friction.

- Cools the workpiece and prevents overheating.

- Suspends abrasive particles and prevents clogging.

- Enhances the surface finish and reduces defects.

9. How do you inspect the quality of a bevel polished surface?

- Visual inspection: Check for scratches, pits, or other surface defects.

- Microscopic inspection: Use a microscope to examine the surface at higher magnification for fine details.

- Profilometry: Measure the surface roughness and contour using a profilometer.

- Glossmeter: Measure the surface gloss level.

10. Explain the importance of maintaining a consistent polishing technique throughout the process.

- Ensures uniformity and consistency in the surface finish.

- Reduces the risk of creating defects or imperfections due to variations in pressure or speed.

- Improves efficiency and productivity by minimizing rework.

- Enhances the overall quality and appearance of the polished surface.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bevel Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bevel Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bevel polishers are responsible for creating smooth, polished surfaces on metal objects using a variety of tools and techniques. They typically work with different grits of abrasive pads and cloths to achieve the desired finish on workpieces. The key responsibilities of a Bevel Polisher may include:

1. Surface Preparation

Bevel polishers start by preparing the surface of the workpiece to ensure the best possible finish. This may involve tasks such as grinding, sanding, or polishing the surface, depending on its condition.

- Identify surface imperfections and determine the appropriate techniques and materials for preparation

- Remove burrs, scratches, and other defects

- Clean and degrease the surface to enhance adhesive properties for subsequent polishing

2. Bevel Angle Polishing

One of the core tasks of a Bevel Polisher is to create precise angles on the edges of workpieces. This requires careful handling of abrasive tools and a keen eye for detail.

- Select and mount the appropriate tooling (e.g., abrasive belts, stones, or wheels) based on the desired finish

- Set up and operate beveling machines to achieve specific angles and tolerances

- Maintain a consistent angle and pressure during the polishing process

3. Surface Finishing

After the bevel angle is polished, Bevel Polishers focus on achieving the desired surface finish. This may involve using different grits of abrasive pads and cloths or applying special polishing compounds.

- Assess surface roughness and select the appropriate abrasive materials

- Apply polishing compounds and use buffing wheels or pads to achieve a smooth, defect-free finish

- Maintain proper pressure and speed during polishing to minimize surface damage

4. Quality Control and Inspection

Bevel polishers are responsible for ensuring the quality of their work meets the required specifications. This involves conducting regular inspections and adhering to established quality standards.

- Inspect finished workpieces for imperfections, scratches, or other defects

- Verify adherence to dimensional tolerances and surface finish requirements

- Maintain records of inspection results and report any issues that may arise

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to guide candidates in acing their Bevel Polisher interview:

1. Research the Company and Role

Take the time to learn about the company’s history, industry, and values. Understanding the company’s business and culture will help you tailor your responses to their specific requirements.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Connect with current or former employees on LinkedIn

2. Highlight Relevant Skills and Experience

Be sure to emphasize the skills and experience that align with the key responsibilities of a Bevel Polisher. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Showcase your proficiency in surface preparation techniques

- Describe your experience in bevel angle polishing and surface finishing

- Highlight your understanding of quality control standards

3. Prepare Examples of Your Work

If applicable, bring a portfolio or samples of your work to the interview. This will provide the interviewer with tangible evidence of your skills and attention to detail.

- Include examples of workpieces you have polished

- Explain the techniques and materials you used

- Discuss the challenges you encountered and how you overcame them

4. Practice Common Interview Questions

Familiarize yourself with common interview questions and prepare your responses. This will help you feel more confident and articulate during the actual interview.

- Tell me about your experience in surface preparation.

- Describe the steps you would take to polish a bevel angle to a specific tolerance.

- What quality control measures do you implement in your work?

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview and arrive punctually. Your professional demeanor and attention to detail will reflect your commitment to the job.

- Wear clean, pressed clothing and polished shoes

- Arrive at the interview location 10-15 minutes early

- Maintain good posture and positive body language throughout the interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bevel Polisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!