Feeling lost in a sea of interview questions? Landed that dream interview for Beveling and Edging Machine Operator Helper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Beveling and Edging Machine Operator Helper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

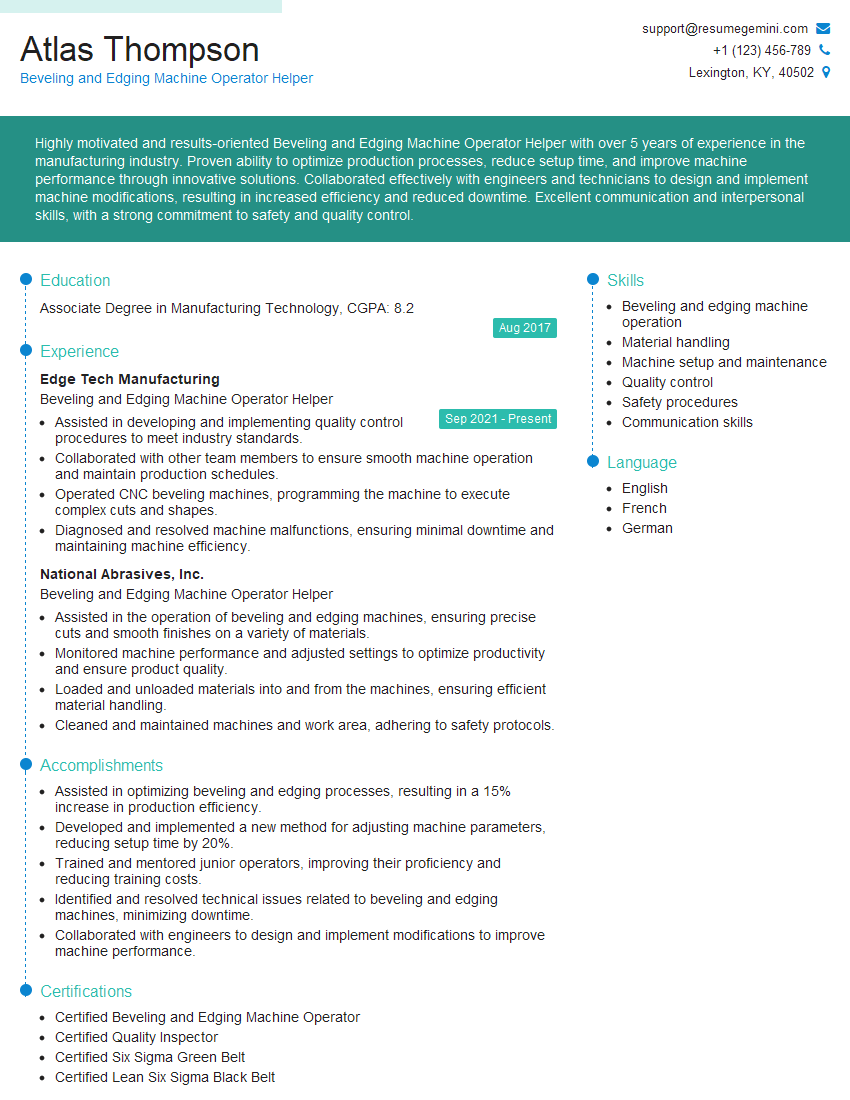

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beveling and Edging Machine Operator Helper

1. What are the different types of beveling machines and their uses?

- Cold saw beveling machine: This machine is used to cut straight or angled cuts on metal pipes and tubes. Can make various angle cuts, miter cuts, and compound cuts.

- Plate beveling machine: This machine is used to bevel the edges of metal plates. It can produce different bevel angles and can handle various plate thicknesses.

- Pipe beveling machine: This machine is used to bevel the edges of metal pipes. It can produce different bevel angles and can handle various pipe diameters.

2. Explain the process of setting up and operating a beveling machine?

Preparing the machine

- Secure the material to be beveled in the machine’s workholding device.

- Select the desired bevel angle and set it on the machine.

- Adjust the machine’s cutting parameters, such as cutting speed, feed rate, and depth of cut.

Operating the machine

- Start the machine and engage the cutting tool with the material.

- Monitor the cutting process and adjust parameters as needed to ensure a clean and accurate bevel.

- Once the beveling process is complete, stop the machine.

3. What safety precautions should be taken when operating a beveling machine?

- Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensure that the machine is properly grounded and that all guards and safety devices are in place.

- Never operate the machine under the influence of drugs or alcohol.

- Be aware of the machine’s operating limits and never exceed them.

- Inspect the machine regularly for any signs of damage or wear and tear.

4. How do you maintain a beveling machine?

- Clean the machine regularly to remove any debris or metal shavings.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the cutting tool regularly and replace it when necessary.

- Check the machine’s electrical connections and wiring regularly.

- Perform regular maintenance checks as per the manufacturer’s recommendations.

5. What are the different types of edge banding machines and their uses?

- Manual edge banding machine: This machine is used to apply edge banding to the edges of panels manually.

- Semi-automatic edge banding machine: This machine is used to apply edge banding to the edges of panels with the help of a conveyor belt.

- Automatic edge banding machine: This machine is used to apply edge banding to the edges of panels fully automatically.

6. Explain the process of setting up and operating an edge banding machine?

Preparing the machine

- Select the desired edge banding material and insert it into the machine.

- Set the machine’s temperature and pressure settings according to the type of edge banding material being used.

- Adjust the machine’s feed rate and cutting speed.

Operating the machine

- Feed the panel to be edged into the machine.

- The machine will automatically apply the edge banding material to the edges of the panel.

- Once the edge banding process is complete, the panel will be ejected from the machine.

7. What safety precautions should be taken when operating an edge banding machine?

- Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensure that the machine is properly grounded and that all guards and safety devices are in place.

- Never operate the machine under the influence of drugs or alcohol.

- Be aware of the machine’s operating limits and never exceed them.

- Inspect the machine regularly for any signs of damage or wear and tear.

8. How do you maintain an edge banding machine?

- Clean the machine regularly to remove any debris or glue residue.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the cutting tool regularly and replace it when necessary.

- Check the machine’s electrical connections and wiring regularly.

- Perform regular maintenance checks as per the manufacturer’s recommendations.

9. What are the different types of edging materials?

- Wood veneer

- Laminate

- PVC

- Acrylic

- Metal

10. How do you choose the right edging material for a particular application?

- Consider the type of substrate being edged.

- Consider the desired appearance of the finished product.

- Consider the durability and wear resistance required.

- Consider the cost of the edging material.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beveling and Edging Machine Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beveling and Edging Machine Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Beveling and Edging Machine Operator Helper assists the operator in setting up, operating, and maintaining beveling and edging machines. They perform various tasks to ensure the smooth functioning of the equipment and the production of high-quality finished products.

1. Assisting with Machine Setup

The helper assists the operator in setting up the machine by loading and unloading materials, adjusting machine settings, and verifying that the equipment is operating correctly.

2. Material Handling

The helper is responsible for handling materials, including loading and unloading heavy workpieces, which requires physical strength and attention to detail.

3. Monitoring Machine Operation

The helper monitors the machine’s operation, checking for any abnormalities or problems. They promptly report any issues to the operator to ensure timely troubleshooting.

4. Maintaining Equipment

The helper assists in maintaining the machine by cleaning, lubricating, and performing minor repairs as needed. They follow established maintenance schedules to ensure optimal equipment performance.

5. Quality Control

The helper visually inspects finished workpieces to ensure they meet quality standards. They may use measuring instruments to verify dimensions and surface finish.

6. Safety Compliance

The helper follows established safety protocols, including wearing appropriate protective gear, operating equipment safely, and maintaining a clean and organized work area.

Interview Tips

1. Research the Company and Industry

Gather information about the company’s history, values, and products. Understand the industry in which they operate and the challenges they face.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Network with individuals in the field.

2. Highlight Relevant Skills and Experience

Emphasize how your skills and experience align with the job requirements. Quantify your accomplishments and provide specific examples to demonstrate your capabilities.

- Discuss your experience in material handling, machine operation, or quality control.

- Highlight your ability to work effectively in a team environment.

- Mention any safety training or certifications you have obtained.

3. Showcase Your Commitment to Safety

Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment. Provide examples of your safety practices.

- Explain your understanding of the company’s safety policies.

- Share examples of how you have implemented safety measures in previous roles.

- Describe how you prioritize safety in your daily work habits.

4. Practice Your Answers

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the interview.

- Prepare answers to questions about your experience, skills, and motivation.

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result).

- Consider potential questions about the company and industry and prepare your responses.

5. Be Enthusiastic and Professional

Demonstrate your interest in the position and the company. Dress professionally, maintain good posture, and make eye contact with the interviewer. Be respectful of their time and ask thoughtful questions.

- Express your enthusiasm for the opportunity and explain why you are interested in the role.

- Be polite and respectful to the interviewer.

- Ask insightful questions about the company, the position, and the industry.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Beveling and Edging Machine Operator Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Beveling and Edging Machine Operator Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.