Are you gearing up for a career in Beveling Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Beveling Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

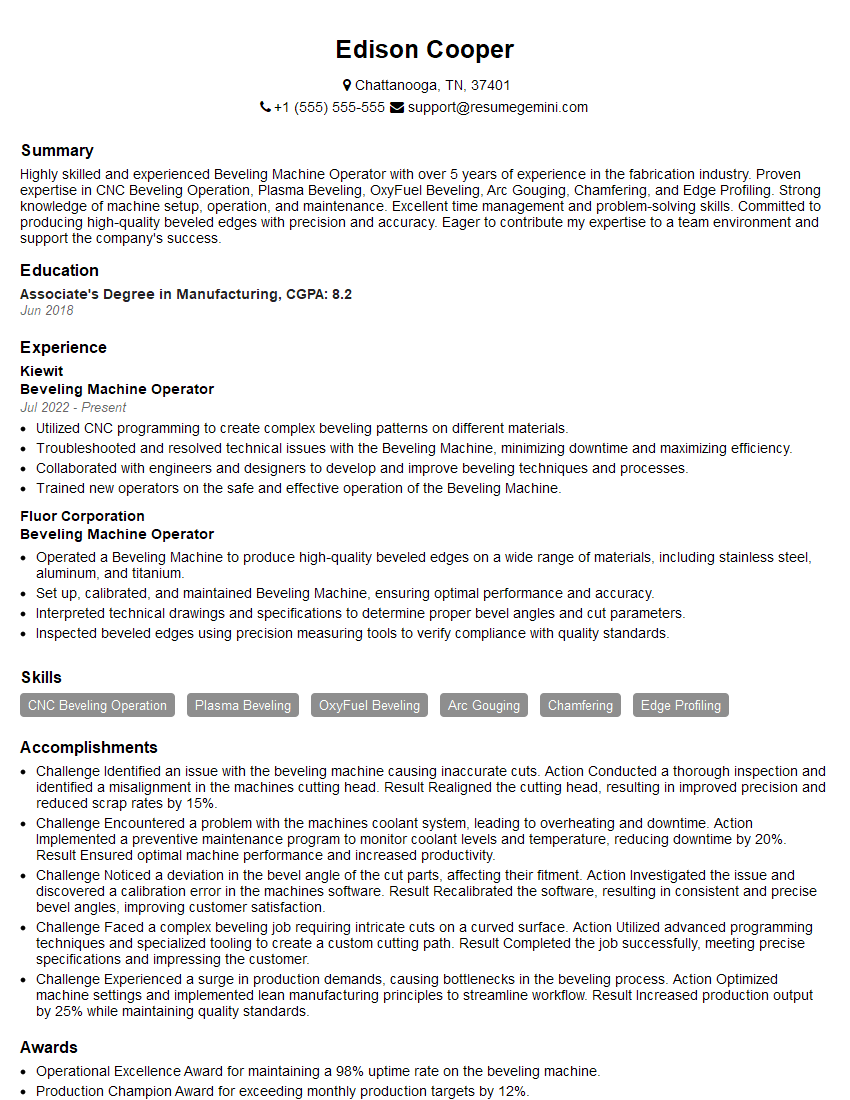

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beveling Machine Operator

1. What are the different types of beveling machines?

There are two main types of beveling machines: manual and automatic. Manual beveling machines are operated by hand, while automatic beveling machines are controlled by a computer. Manual beveling machines are typically used for small or simple beveling jobs, while automatic beveling machines are used for larger or more complex beveling jobs.

2. What are the safety precautions that should be taken when operating a beveling machine?

Wearing the safety glasses

- Always wear safety glasses when operating a beveling machine.

- The metal chips and sparks that are produced by the beveling process can cause serious eye injuries.

Wearing the gloves

- Wear gloves when operating a beveling machine.

- The beveling process can create sharp edges on the metal, which can cut your hands.

3. How do you set up a beveling machine?

The setup of a beveling machine will vary depending on the specific machine that you are using. However, there are some general steps that you can follow. First, you will need to select the correct beveling angle and depth. Next, you will need to secure the metal that you are going to bevel in the machine. Finally, you will need to start the machine and carefully guide the metal through the beveling process.

4. How do you maintain a beveling machine?

- Regularly clean the beveling machine to remove any metal chips or debris.

- Inspect the beveling machine regularly for any signs of wear or damage.

- Lubricate the beveling machine according to the manufacturer’s instructions.

5. What are the different types of bevels that can be created with a beveling machine?

- V-bevels

- U-bevels

- J-bevels

- Chamfers

6. What are the advantages of using a beveling machine?

- Beveling machines can create precise and consistent bevels.

- Beveling machines can save time and labor costs.

- Beveling machines can improve the quality of your finished product.

7. What are the disadvantages of using a beveling machine?

- Beveling machines can be expensive to purchase and maintain.

- Beveling machines can be dangerous to operate if they are not used properly.

8. What is the difference between a bevel and a chamfer?

- A bevel is a sloping edge, while a chamfer is a beveled edge that is cut at a 45-degree angle.

- Bevils are typically used to join two pieces of metal together, while chamfers are typically used to create a decorative edge.

9. What are the different materials that can be beveled with a beveling machine?

- Beveling machines can be used to bevel a variety of materials, including metal, plastic, and wood.

- The type of material that you can bevel will depend on the specific beveling machine that you are using.

10. What are the different applications for beveling machines?

- Beveling machines are used in a variety of applications, including shipbuilding, automotive manufacturing, and aerospace manufacturing.

- Beveling machines can be used to create beveled edges on a variety of parts, including pipes, tubes, and plates.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beveling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beveling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Beveling Machine Operator is responsible for operating and maintaining beveling machines to create angled edges on metal materials. Their key job responsibilities include:

1. Machine Operation

Setting up and operating beveling machines to create angled cuts on metal materials.

- Adjusting machine settings to achieve desired angles and dimensions.

- Loading and unloading metal materials.

2. Quality Control

Inspecting finished products to ensure they meet specifications.

- Checking bevel angle, dimensions, and surface finish.

- Identifying and correcting any defects or errors.

3. Maintenance and Troubleshooting

Performing routine maintenance and troubleshooting on beveling machines.

- Lubricating and cleaning machine components.

- Identifying and resolving malfunctions or breakdowns.

4. Safety and Compliance

Adhering to safety regulations and operating procedures.

- Wearing appropriate safety gear.

- Following established safety protocols.

Interview Tips

To ace the interview for a Beveling Machine Operator position, candidates should consider the following tips:

1. Research the Company and Role

Thoroughly research the company and the specific job requirements.

- Visit the company website and review their products, services, and values.

- Study the job description to understand the responsibilities and qualifications.

2. Practice Your Skills

Be prepared to demonstrate your skills and knowledge.

- Review the basics of beveling, including angles, dimensions, and materials.

- Practice operating a beveling machine if possible.

3. Highlight Your Relevant Experience

Emphasize your previous experience operating beveling machines or working in a similar role.

- Quantify your accomplishments using specific examples.

- Explain how your skills and expertise align with the job requirements.

4. Show Motivation and Enthusiasm

Convey your interest in the position and the industry.

- Explain why you are passionate about beveling and metalworking.

- Express your eagerness to learn and contribute to the team.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Beveling Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.