Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Beveller Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

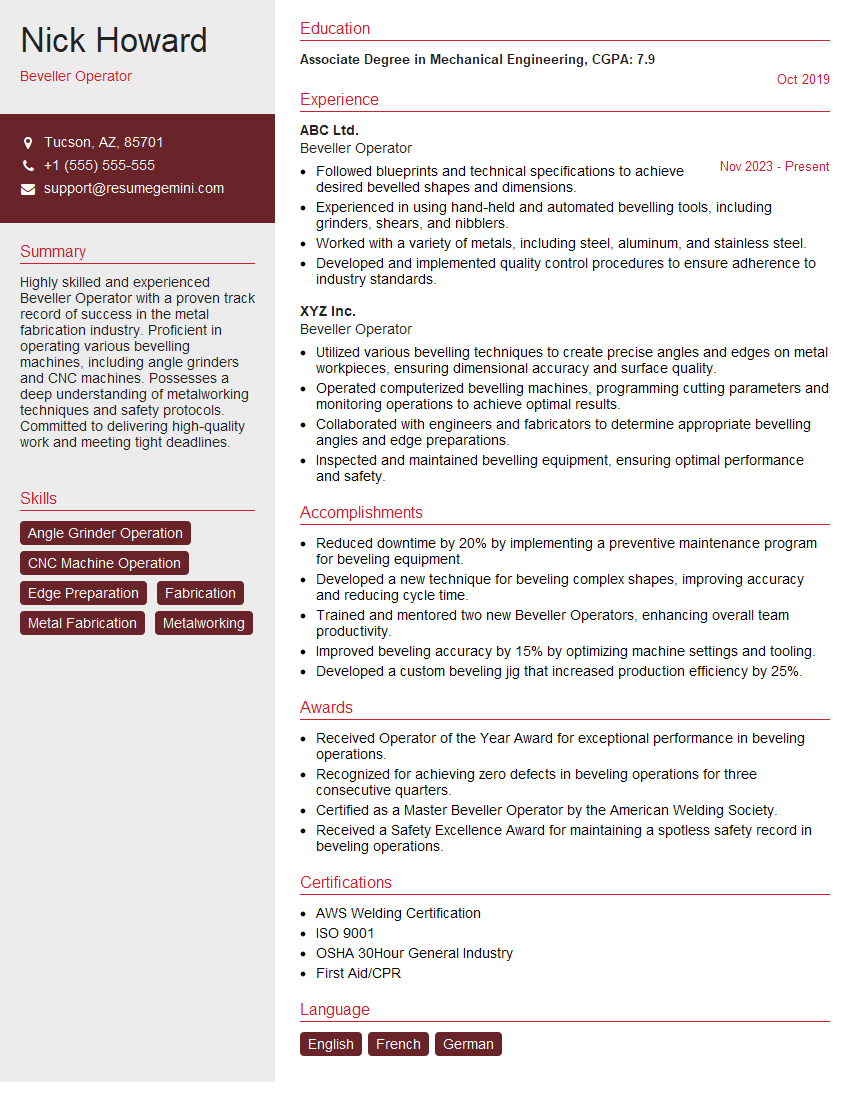

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beveller Operator

1. Describe the process of beveling?

Beveling is a process of creating an angled edge on a material, typically metal. It is used to prepare materials for welding, painting, or other processes. The process involves using a beveling machine to cut the material at a specific angle.

- The first step is to select the appropriate beveling machine for the material and the desired angle.

- The material is then placed on the machine and secured in place.

- The machine is then set to the desired angle and the cutting process is initiated.

- Once the cutting process is complete, the beveled edge is inspected to ensure that it meets the required specifications.

2. What are the different types of beveling machines?

There are two main types of beveling machines: manual and automatic.

Manual beveling machines

- These machines require the operator to manually control the cutting process.

- They are typically used for small or one-off jobs.

Automatic beveling machines

- These machines are computer-controlled and can perform complex beveling operations.

- They are typically used for large or repetitive jobs.

3. What are the factors that affect the quality of a beveled edge?

The quality of a beveled edge is affected by a number of factors, including:

- The type of material being beveled

- The thickness of the material

- The angle of the bevel

- The speed of the cutting process

- The skill of the operator

4. What are the safety precautions that should be taken when operating a beveling machine?

When operating a beveling machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Ensure that the machine is properly grounded.

- Keep the work area clean and free of debris.

- Never operate the machine under the influence of alcohol or drugs.

- Be aware of the potential hazards associated with the machine, such as flying sparks and sharp edges.

5. What are the common problems that can occur when beveling?

There are a number of common problems that can occur when beveling, including:

- The bevel is not the correct angle.

- The bevel is not smooth.

- The bevel is too wide or too narrow.

- The material is damaged during the beveling process.

6. How do you troubleshoot a beveling machine?

If you are experiencing problems with a beveling machine, you can try the following troubleshooting tips:

- Check the machine for any loose or damaged parts.

- Make sure that the machine is properly grounded.

- Check the cutting blade for any damage or wear.

- Adjust the machine settings according to the manufacturer’s instructions.

- If the problem persists, contact the manufacturer for assistance.

7. What are the different types of bevels?

There are a number of different types of bevels, including:

- Single bevel

- Double bevel

- Compound bevel

- J-bevel

- V-bevel

8. What is the difference between a bevel and a chamfer?

A bevel is an angled edge, while a chamfer is a sloped edge. Bevels are typically used to prepare materials for welding, while chamfers are typically used to remove sharp edges.

9. What are the applications of beveling?

Beveling has a wide range of applications, including:

- Welding

- Painting

- Metalworking

- Woodworking

- Glassworking

10. What are the benefits of using a beveling machine?

Using a beveling machine offers a number of benefits, including:

- Increased precision

- Reduced labor costs

- Improved safety

- Enhanced productivity

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beveller Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beveller Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Beveller Operator plays a crucial role in preparing metal edges for welding or other fabrication processes. Here are some key job responsibilities:

1. Bevelling and Preparing Metal Edges

The primary task of a Beveller Operator is to bevel metal edges using specialized equipment such as a bevelling machine or hand-held tools. Bevelling involves creating a precise angle or chamfer to facilitate welding and ensure proper joint penetration.

- Operate bevelling machines to create specific bevel angles and edge preparations

- Use hand-held tools such as grinders or oxy-acetylene torches for manual bevelling

2. Measuring and Inspection

To ensure accuracy and meet specifications, Beveller Operators are responsible for measuring and inspecting the beveled edges. They use measuring instruments like calipers or micrometers to verify angles, dimensions, and surface finish.

- Inspect beveled edges for accuracy and conformance to drawings

- Use measuring tools to verify angles, dimensions, and surface finish

3. Machine Setup and Maintenance

Beveller Operators are often responsible for setting up and maintaining their equipment. They ensure that machines are calibrated correctly, have the appropriate consumables, and are operating safely and efficiently.

- Set up and calibrate bevelling machines

- Perform routine maintenance and troubleshooting on equipment

4. Safety and Compliance

Operating bevelling equipment involves potential hazards. Beveller Operators are required to follow safety protocols, wear personal protective equipment, and ensure that their work area is organized and free from trip or fall hazards.

- Follow established safety guidelines and procedures

- Wear personal protective equipment to prevent injuries

- Maintain a clean and safe work environment

Interview Tips

Preparing for a Beveller Operator interview requires a combination of technical knowledge and demonstrating a strong work ethic. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Spend time researching the company’s background, industry, and specific requirements for the Beveller Operator role. This will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company website and social media pages

- Read industry publications and articles

- Connect with current or former employees on LinkedIn

2. Highlight Your Technical Skills

Emphasize your proficiency in operating bevelling machines and hand-held tools. Quantify your experience and provide specific examples of projects where you successfully beveled metal edges to meet specified requirements.

- Discuss your experience with different types of bevelling machines

- Provide examples of projects where you achieved precise bevel angles

- Highlight your knowledge of metallurgy and welding processes

3. Showcase Your Attention to Detail

Bevelling requires precision and attention to detail. Highlight your ability to carefully measure and inspect beveled edges to ensure accuracy. Discuss your commitment to quality and your ability to meet tight tolerances.

- Describe your experience with measuring instruments and inspection techniques

- Provide examples of projects where you identified and corrected errors in bevelling

- Emphasize your ability to work independently and follow instructions precisely

4. Showcase Your Safety Awareness

Safety is paramount in operating bevelling equipment. Discuss your understanding of safety protocols and your commitment to following them. Highlight any safety training or certifications you possess.

- Describe your knowledge of potential hazards associated with bevelling

- Discuss your experience in wearing personal protective equipment

- Explain your understanding of emergency procedures

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Beveller Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Beveller Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.