Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bias Cutting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bias Cutting Machine Operator so you can tailor your answers to impress potential employers.

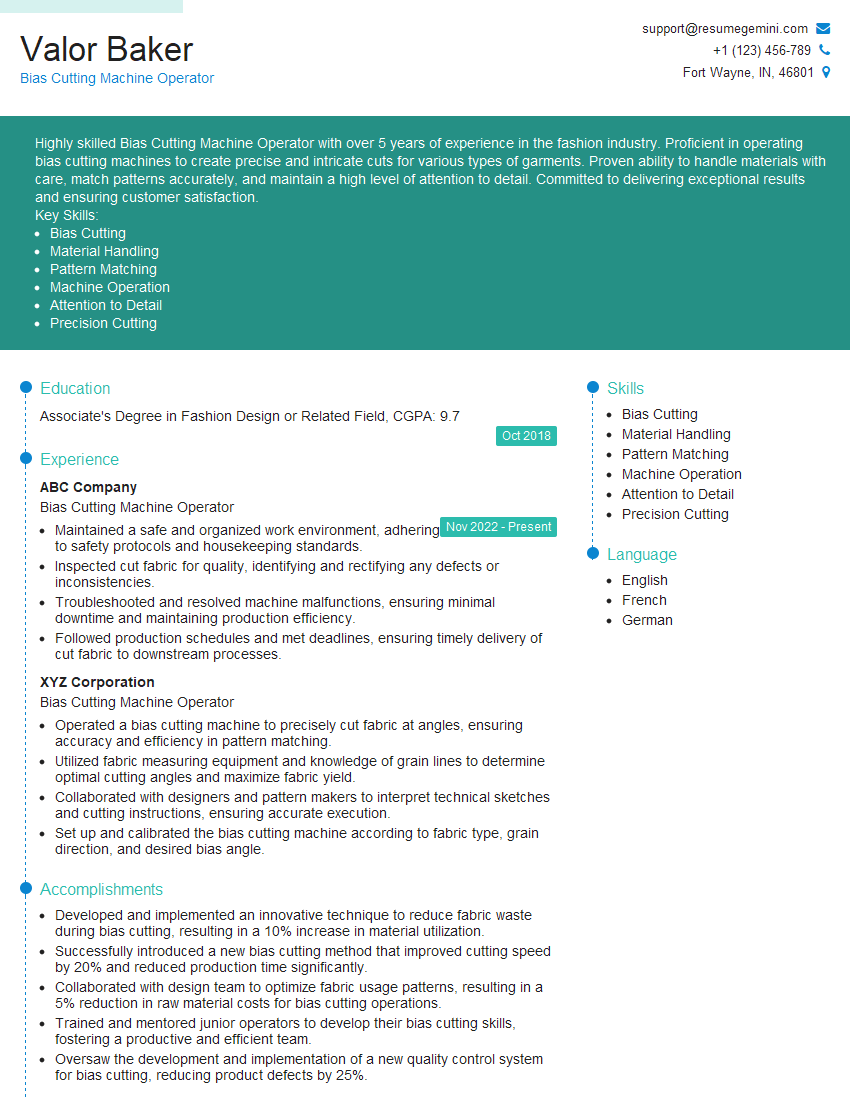

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bias Cutting Machine Operator

1. Describe the process of setting up a bias cutting machine.

- Inspect the machine for any damage or malfunctions.

- Install the blade and adjust its tension.

- Set the cutting angle and bias width.

- Load the fabric onto the machine and align it with the cutting path.

- Secure the fabric with clamps or weights.

2. What types of fabrics can be cut on a bias cutting machine?

Woven fabrics

- Cotton

- Linen

- Silk

- Wool

Knitted fabrics

- Jersey

- Ribbing

- Interlock

- French terry

3. What are the advantages of using a bias cutting machine?

- Cuts fabric with precision and accuracy.

- Creates smooth, clean cuts without fraying.

- Allows for the creation of complex bias cuts.

- Improves the quality and drape of the finished garment.

4. What are the safety precautions that must be taken when operating a bias cutting machine?

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands away from the cutting blade.

- Unplug the machine before making any adjustments.

- Keep the machine clean and in good working order.

- Follow all manufacturer’s instructions.

5. How do you troubleshoot common problems that may occur when operating a bias cutting machine?

- Blade is dull or damaged: Replace the blade.

- Machine is not cutting accurately: Check the blade tension and alignment.

- Fabric is slipping: Secure the fabric more tightly with clamps or weights.

- Machine is making a loud noise: Inspect the machine for any loose or damaged parts.

- Machine is not cutting bias correctly: Check the cutting angle and bias width settings.

6. What maintenance procedures are required for a bias cutting machine?

- Clean the machine regularly with a damp cloth.

- Oil the machine according to the manufacturer’s instructions.

- Inspect the blade regularly for wear and tear.

- Have the machine serviced by a qualified technician as needed.

7. What are the different types of bias cutting machines available?

- Manual bias cutting machines

- Semi-automatic bias cutting machines

- Automatic bias cutting machines

- Computer-controlled bias cutting machines

8. What are the factors to consider when choosing a bias cutting machine?

- Type of fabric to be cut

- Bias width required

- Cutting speed and accuracy

- Machine size and portability

- Budget

9. What is the difference between a bias cut and a straight cut?

- Bias cut: The fabric is cut at an angle to the grain line, creating a stretchy and fluid fabric.

- Straight cut: The fabric is cut parallel to the grain line, creating a more structured and stable fabric.

10. What are some applications for bias cut fabrics?

- Clothing: Dresses, skirts, blouses, pants

- Accessories: Scarves, ties, headbands

- Home decor: Curtains, tablecloths, pillows

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bias Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bias Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bias Cutting Machine Operators are responsible for operating and maintaining bias cutting machines, which are used to cut fabric on a bias. This involves setting up the machine, loading the fabric, and operating the machine to cut the fabric according to specifications.

1. Setting Up the Machine

Bias Cutting Machine Operators must ensure that the machine is properly set up before beginning operation. This involves checking the machine’s settings, adjusting the blade, and loading the fabric. Operators must also ensure that the machine is properly lubricated and maintained.

2. Operating the Machine

Once the machine is properly set up, Bias Cutting Machine Operators operate the machine to cut the fabric according to specifications. This involves feeding the fabric into the machine and guiding it through the cutting blade. Operators must also monitor the machine’s operation to ensure that the fabric is being cut correctly.

3. Maintaining the Machine

Bias Cutting Machine Operators are also responsible for maintaining the machine. This involves cleaning the machine, lubricating the moving parts, and making minor repairs. Operators must also inspect the machine regularly to identify potential problems.

4. Troubleshooting

If the machine experiences any problems, Bias Cutting Machine Operators must troubleshoot the problem and make repairs. This may involve replacing a blade, adjusting a setting, or cleaning a part.

Interview Tips

Preparing for an interview for a Bias Cutting Machine Operator position can be a daunting task. Here are a few tips to help you ace the interview and land the job.

1. Research the Company and the Position

Take some time to research the company you are applying to and the specific position you are interested in. This will help you understand the company’s culture, values, and expectations for the role.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Highlight Your Skills and Experience

Make sure to highlight your skills and experience that are relevant to the position you are applying for. Be specific and provide examples of your work. For example, if you have experience operating a bias cutting machine, be sure to mention this in your interview.

4. Be Enthusiastic and Professional

First impressions matter, so be sure to be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and be polite to everyone you meet. Also, be prepared to answer questions about your experience, skills, and why you are interested in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bias Cutting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!