Are you gearing up for an interview for a Billet Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Billet Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

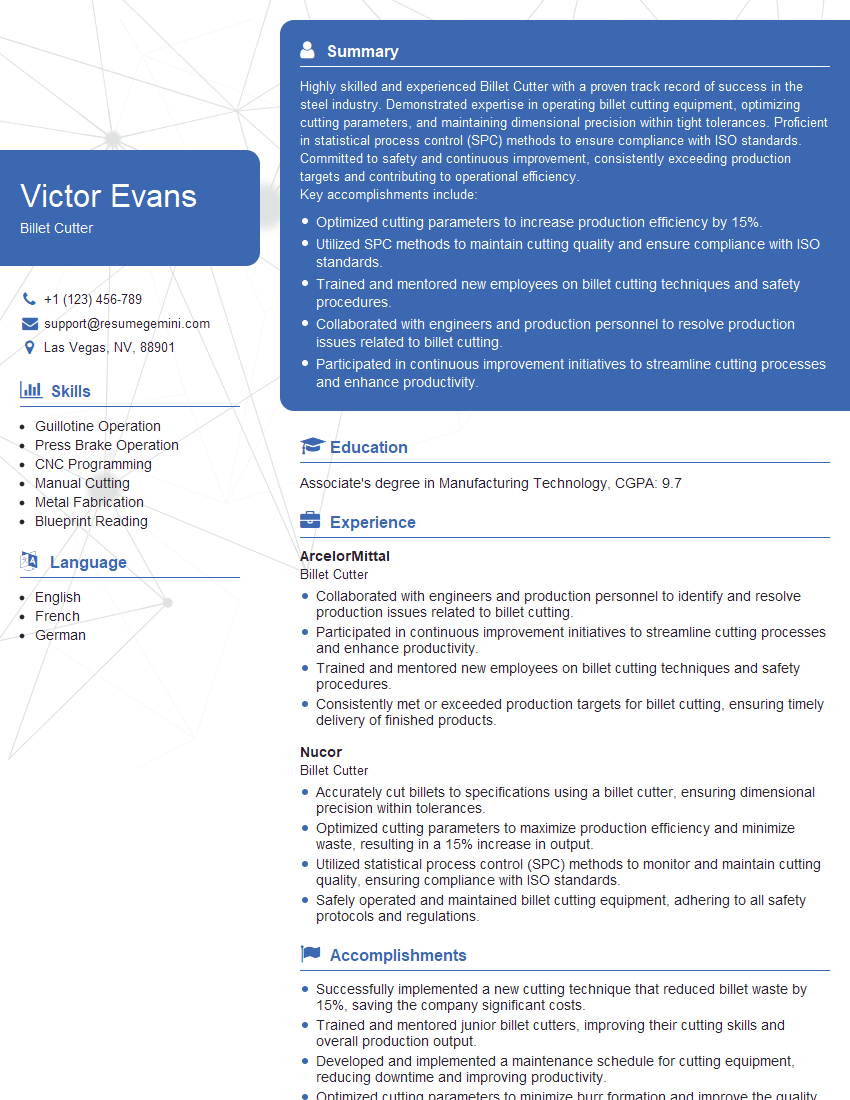

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Billet Cutter

1. Explain the process of cutting billets according to the specifications provided?

The process of cutting billets according to the specifications provided typically involves the following steps:

- Receiving the billet and specifications: The billet cutter receives the billet and the specifications for the desired cut.

- Setting up the cutting machine: The cutter sets up the cutting machine according to the specified dimensions and tolerances.

- Loading the billet into the machine: The billet is loaded into the machine and secured in place.

- Cutting the billet: The cutting machine is operated to cut the billet according to the specifications.

- Inspecting the cut billet: The cut billet is inspected to ensure that it meets the required dimensions and tolerances.

- Unloading the cut billet: The cut billet is unloaded from the machine and stacked or packaged for storage or further processing.

2. What are the different types of billet cutting machines and their applications?

Shear Cutting Machine

- Uses blades to cut billets by applying shear force.

- Suitable for cutting large-diameter billets with high precision.

Cold Saw Cutting Machine

- Employs a rotating circular saw blade to cut billets.

- Provides high cutting speed and produces clean cuts.

Plasma Arc Cutting Machine

- Uses a plasma arc to melt and vaporize the billet material.

- Suitable for cutting complex shapes or hard-to-cut materials.

3. How do you ensure accuracy and precision when cutting billets?

To ensure accuracy and precision when cutting billets, I employ the following techniques:

- Proper machine calibration: Regularly calibrate the cutting machine to maintain accurate dimensions.

- Precise measurement: Use precision measuring tools to accurately mark the cutting points.

- Sharp cutting tools: Ensure that the cutting tools are sharp and in good condition to prevent deviations.

- Stable cutting environment: Maintain a stable temperature and humidity in the cutting area to minimize material expansion or contraction.

- Careful handling: Handle the billets carefully to avoid bending or warping that could affect the cutting accuracy.

4. What are the safety precautions to be taken while operating a billet cutting machine?

To ensure safety while operating a billet cutting machine, I strictly adhere to the following precautions:

- Personal protective equipment: Wear appropriate safety gear, including gloves, eye protection, and hearing protection.

- Machine guarding: Keep all machine guards in place and ensure they are functioning properly.

- Proper grounding: Ensure that the machine is properly grounded to prevent electrical hazards.

- Safe handling practices: Use proper lifting techniques and avoid touching sharp edges.

- Emergency stop: Know the location of the emergency stop button and be ready to use it in case of any emergency.

5. How do you optimize the cutting process to increase efficiency and reduce waste?

To optimize the cutting process and enhance efficiency, I implement the following strategies:

- Batch cutting: Cut multiple billets simultaneously to reduce setup time and increase throughput.

- Nesting techniques: Arrange the billets on the cutting bed to maximize material utilization and minimize waste.

- Automated loading and unloading: Use automated systems to load and unload billets, reducing manual labor and increasing productivity.

- Regular maintenance: Perform regular maintenance on the cutting machine to ensure optimal performance and prevent breakdowns.

6. Describe the different types of materials that can be cut using a billet cutting machine and their respective cutting parameters.

Different types of materials that can be cut using a billet cutting machine include:

- Steel: Requires high cutting speeds and appropriate blade selection based on the steel grade.

- Aluminum: Requires higher cutting speeds and specialized cutting tools to prevent smearing.

- Copper: Excellent thermal conductivity, necessitating slower cutting speeds to avoid overheating.

- Brass: Similar to copper, requires slower cutting speeds and specific tool geometry to prevent burr formation.

7. Explain the role of coolant in the billet cutting process.

Coolant plays a crucial role in the billet cutting process by providing the following benefits:

- Lubrication: Reduces friction between the cutting tool and the billet, minimizing wear and tear.

- Cooling: Dissipates heat generated during cutting, preventing overheating and maintaining tool life.

- Chip removal: Washes away chips and debris, improving cutting accuracy and surface finish.

- Corrosion protection: Protects the cut surface from corrosion and oxidation.

8. Discuss the importance of regular maintenance and calibration of a billet cutting machine.

Regular maintenance and calibration of a billet cutting machine are essential for ensuring optimal performance and longevity, as they:

- Prevent breakdowns: Regular maintenance helps identify and address potential issues before they escalate into costly breakdowns.

- Maintain accuracy: Calibration ensures that the machine consistently cuts billets to the desired dimensions and tolerances.

- Extend machine life: Proper maintenance and calibration prolong the service life of the machine by reducing wear and tear.

- Improve safety: Well-maintained machines operate safely, reducing the risk of accidents or injuries.

9. What are the common challenges faced in billet cutting and how do you overcome them?

Common challenges in billet cutting and how to overcome them include:

Billet distortion

- Use sharp cutting tools and maintain proper cutting parameters to minimize distortion.

Burr formation

- Select appropriate cutting tools and techniques based on the material being cut.

Heat buildup

- Employ proper coolant and cutting speeds to prevent overheating and ensure tool longevity.

10. How do you stay updated on the latest advancements in billet cutting technology?

To stay updated on the latest advancements in billet cutting technology, I:

- Attend industry events and conferences: Participate in seminars and exhibitions to learn about new technologies and best practices.

- Read technical journals and articles: Subscribe to industry publications to stay informed about technological developments.

- Network with industry professionals: Engage with other billet cutters and experts to exchange knowledge and insights.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Billet Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Billet Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Billet Cutters are responsible for operating and maintaining billet cutting machines. They use these machines to cut large blocks of metal into smaller, more manageable pieces.

1. Operate Billet Cutting Machine

Billet Cutters are responsible for the safe and efficient operation of billet cutting machines. They must be able to set up and operate the machine, as well as troubleshoot any problems that may occur.

- Set up and operate billet cutting machine

- Troubleshoot and repair machine problems

2. Cut Billets

Billet Cutters are responsible for cutting billets to the specified dimensions. They must be able to accurately and precisely cut the billets, as well as maintain the quality of the cut.

- Cut billets to specified dimensions

- Maintain quality of cut

3. Inspect Billets

Billet Cutters are responsible for inspecting the billets after they have been cut. They must be able to identify any defects in the billets, as well as ensure that the billets meet the specifications.

- Inspect billets for defects

- Ensure that billets meet specifications

4. Maintain Work Area

Billet Cutters are responsible for maintaining their work area. They must be able to keep the area clean and organized, as well as ensure that all equipment is in good working condition.

- Maintain work area

- Keep area clean and organized

- Ensure that all equipment is in good working condition

Interview Tips

Preparing for an interview can be stressful, but there are some things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Billet Cutter position:

1. Research the Company and the Position

Before you go on an interview, it’s important to do your research. Learn as much as you can about the company and the position you’re applying for. This will help you answer questions intelligently and show the interviewer that you’re genuinely interested in the opportunity.

- Visit the company’s website and read about their history, mission, and values.

- Look up the position you’re applying for on the company’s website or on job boards.

- Talk to people in your network who may know about the company or the position.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked, regardless of the position you’re applying for. It’s a good idea to practice answering these questions in advance so that you can feel more confident and prepared during your interview.

Here are a few examples of common interview questions:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- Do you have any questions for me?

3. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re respectful of their time and that you’re taking the interview seriously.

- Wear a clean, pressed suit or dress.

- Make sure your shoes are polished.

- Arrive at the interview location 10-15 minutes early.

4. Be Yourself and Be Enthusiastic

It’s important to be yourself and be enthusiastic during your interview. The interviewer wants to get to know you and see if you’re a good fit for the position. So don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Billet Cutter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.