Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Billet Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

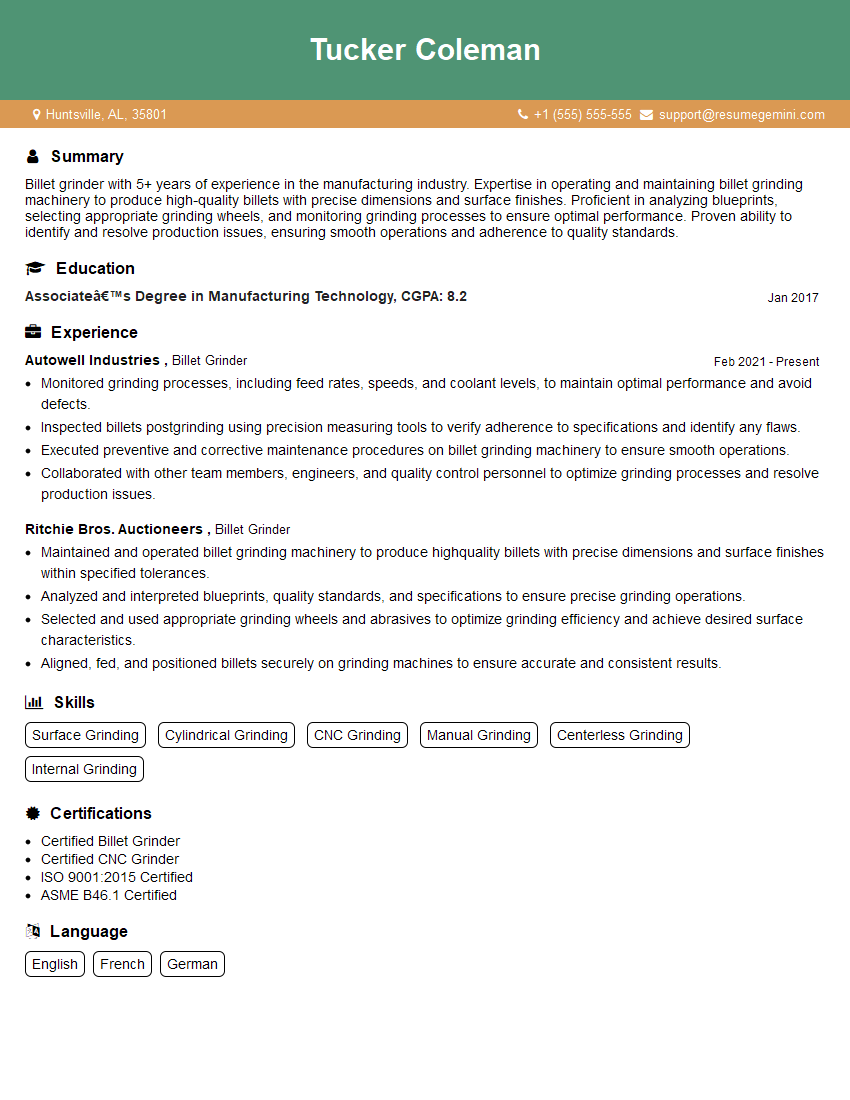

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Billet Grinder

1. How do you ensure that the billet is ground to the correct dimensions?

To ensure the billet is ground to the correct dimensions, I follow a meticulous process:

- Precise Measurement: Before grinding, I carefully measure the billet using precision instruments to determine its exact dimensions.

- Grinding Plan Development: Based on the measurements, I develop a grinding plan that outlines the specific steps and techniques required to achieve the desired dimensions.

- Machine Calibration: I meticulously calibrate the grinding machine according to the grinding plan, ensuring accurate settings and optimal performance.

- Continual Monitoring: During the grinding process, I continuously monitor the billet’s dimensions using gauges and measuring devices to make any necessary adjustments in real-time.

- Post-Grinding Inspection: Upon completion, I conduct a thorough inspection of the billet using precision measuring tools to verify that the final dimensions meet the specified tolerances.

2. What are the different types of grinding wheels used in billet grinding?

Conventional Abrasive Wheels:

- Aluminum Oxide: Versatile and cost-effective for general-purpose grinding

- Silicon Carbide: More aggressive, suitable for tough materials and heavy stock removal

Superabrasive Wheels:

- Cubic Boron Nitride (CBN): High hardness and wear resistance, excellent for grinding hardened steels

- Diamond: Exceptional wear resistance, ideal for grinding non-ferrous metals and composites

Other Specialized Wheels:

- Electroplated Wheels: Consistent performance, high precision, and extended lifespan

- Resin-bonded Wheels: Flexible and conformable, suitable for complex shapes and intricate grinding

3. What are the factors that affect the surface finish of a ground billet?

- Grinding Wheel Selection: The type and grit of the grinding wheel play a critical role in determining the surface finish.

- Grinding Parameters: The speed, feed rate, and depth of cut all influence the surface finish.

- Billet Material: The hardness, toughness, and composition of the billet can affect the surface finish.

- Machine Condition: Regular maintenance and calibration of the grinding machine ensure optimal performance and a consistent surface finish.

- Coolant: The use of appropriate coolants can reduce friction, prevent thermal damage, and improve surface quality.

4. How do you troubleshoot common problems encountered in billet grinding?

- Excessive Vibration: Check wheel balance, machine alignment, and workpiece clamping.

- Poor Surface Finish: Adjust grinding parameters, select a more suitable grinding wheel, or inspect the machine for any issues.

- Wheel Loading: Use a dressing tool to remove built-up material from the grinding wheel, adjust the infeed rate, or switch to a more open-structured wheel.

- Chattering: Reduce feed rate, increase wheel speed, or modify the workpiece setup to minimize deflection.

- Burn Marks: Reduce grinding force, use a coolant, or adjust the grinding parameters to prevent overheating.

5. What safety precautions should be followed when operating a billet grinder?

- Wear appropriate PPE: Safety glasses, earplugs, gloves, and protective clothing

- Inspect the machine: Ensure it is in good working order before use

- Clear the work area: Remove any debris or obstacles that could cause accidents

- Secure the billet: Use clamps or fixtures to hold the billet firmly in place

- Avoid loose clothing: Wear tight-fitting clothing to prevent entanglement

- Follow proper procedures: Never reach over the moving grinding wheel

6. How do you maintain a billet grinder to ensure its longevity and optimal performance?

- Regular Cleaning: Remove dust, debris, and swarf from the machine after each use

- Wheel Dressing: Use a dressing tool to keep the grinding wheel balanced and free of build-up

- Spindle Maintenance: Lubricate and adjust the spindle as per the manufacturer’s instructions

- Coolant System Upkeep: Ensure the coolant system is clean, well-maintained, and supplied with an appropriate coolant

- Regular Inspection: Conduct periodic inspections to identify and address any potential issues early on

7. What quality control measures do you implement to ensure the consistency and accuracy of ground billets?

- Incoming Material Inspection: Verify the dimensions and quality of the billets before grinding

- In-Process Monitoring: Measure the billet’s dimensions during the grinding process to identify and correct any deviations

- Post-Grinding Inspection: Conduct a thorough inspection of the finished billets to ensure they meet the specified tolerances

- Record Keeping: Maintain detailed records of all grinding parameters, inspections, and measurements

- Continuous Improvement: Regularly review quality data to identify areas for improvement in the grinding process

8. What is the importance of coolant in billet grinding?

- Lubrication: Coolant reduces friction between the grinding wheel and the billet, minimizing wear and tear

- Cooling: Coolant helps dissipate heat generated during grinding, preventing thermal damage to the billet

- Chip Removal: Coolant flushes away grinding chips, improving surface finish and preventing wheel loading

- Rust Prevention: Coolant can contain anti-corrosion agents to protect the billet from rust after grinding

- Improved Wheel Life: Coolant extends the lifespan of the grinding wheel by reducing wear and tear

9. How do you handle grinding large-diameter billets?

- Specialized Equipment: Use a machine designed for grinding large-diameter billets, with a large worktable and sufficient power

- Proper Clamping: Secure the billet firmly using multiple clamps or a chuck to prevent slipping or vibration

- Multi-Pass Grinding: Grind the billet in multiple passes, gradually removing material and achieving the desired dimensions

- Wheel Selection: Choose a grinding wheel with appropriate grit and bond strength to handle the large surface area

- Safety Precautions: Exercise extra caution when handling and grinding large billets due to their weight and potential hazards

10. What are the advantages of using CNC billet grinders over manual grinders?

- Precision: CNC grinders provide consistent and accurate grinding results due to precise control of machine movements

- Efficiency: CNC grinders automate the grinding process, reducing cycle times and increasing productivity

- Complexity: CNC grinders can handle complex grinding operations, including contour grinding and multi-axis grinding

- Repeatability: CNC grinders can produce identical parts with high repeatability, ensuring consistency in quality

- Reduced Operator Error: CNC grinders minimize the risk of human error, leading to improved accuracy and efficiency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Billet Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Billet Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Billet Grinders are responsible for grinding and finishing metal billets into various shapes and sizes. They use a variety of grinding machines and tools to remove excess material and create smooth, accurate surfaces.

1. Preparation and Setup

Billet Grinders typically work with large, heavy billets that must be properly prepared and secured before grinding. This may involve using cranes or hoists to move the billets into place, as well as aligning and clamping them securely to the grinding machine.

- Position and secure billets in the grinding machine using cranes, hoists, clamps, and other equipment.

- Inspect billets for defects, damage, or other issues that may affect the grinding process.

- Adjust and calibrate the grinding machine according to the required specifications and desired finish.

2. Grinding and Finishing

Billet Grinders use a variety of grinding machines, including surface grinders, cylindrical grinders, and centerless grinders. They select the appropriate grinding wheel and speed for the material being ground and the desired finish.

- Operate grinding machines to remove excess material, shape billets, and achieve the required dimensions and tolerances.

- Monitor the grinding process to ensure that the billet is being ground evenly and to the desired specifications.

- Inspect the finished billets for defects, such as cracks, scratches, or burrs, and correct any issues.

3. Maintenance and Repair

Billet Grinders are responsible for maintaining and repairing their own equipment. This includes regular cleaning, lubrication, and adjustment of the grinding machines. They may also need to troubleshoot and repair minor issues.

- Perform routine maintenance and repairs on grinding machines, including cleaning, lubrication, and adjustment.

- Troubleshoot and resolve minor equipment issues to minimize downtime and ensure efficient operation.

- Report major equipment problems or repairs to supervisors or maintenance personnel.

4. Safety and Quality Control

Billet Grinders must always prioritize safety when operating grinding machines. They must wear appropriate safety gear, such as gloves, safety glasses, and earplugs, and follow all safety procedures.

- Follow all safety procedures and wear appropriate personal protective equipment (PPE).

- Inspect billets and grinding machines regularly to ensure that they are in good working order.

- Maintain a clean and organized work area to minimize hazards and improve productivity.

Interview Tips

Preparing well for a Billet Grinder interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company and the specific Billet Grinder position you are applying for. This will help you understand the company’s culture, values, and expectations, and tailor your answers accordingly.

- Visit the company website and social media pages to gather information about their business, products or services, and recent news or announcements.

- Review the job description carefully and highlight the key skills and responsibilities required for the role.

2. Practice Your Answers

Think about common interview questions and prepare your answers in advance. This will help you feel more confident and articulate during the interview.

- Prepare answers to questions about your experience, skills, and qualifications for the role.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your work.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your relevant skills and experience that make you a suitable candidate for the position. Emphasize your abilities in grinding, finishing, and equipment maintenance.

- Quantify your accomplishments whenever possible to provide tangible evidence of your skills and impact.

- Discuss your experience working with different types of grinding machines and the materials you have ground.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and genuinely interested in the position and the company. It also gives you an opportunity to clarify any details or address any concerns.

- Prepare questions about the company’s growth plans, the specific responsibilities of the Billet Grinder role, or the training and development opportunities available.

- Avoid asking questions that are purely personal or unrelated to the position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Billet Grinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Billet Grinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.