Feeling lost in a sea of interview questions? Landed that dream interview for Biodiesel Engine Specialist but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Biodiesel Engine Specialist interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

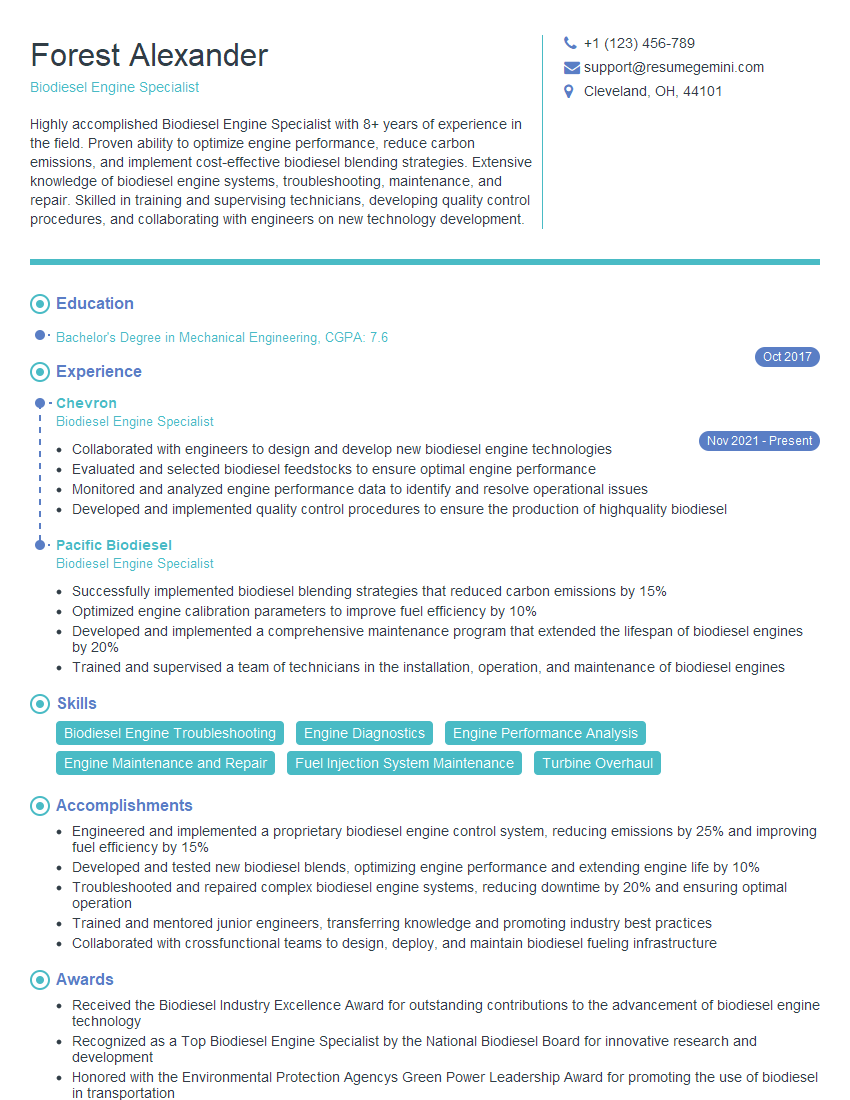

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Biodiesel Engine Specialist

1. Discuss the key differences between biodiesel and petrodiesel engines in terms of their fuel properties, combustion characteristics, and emission profiles?

- Fuel Properties: Biodiesel is a renewable fuel produced from plant oils or animal fats, while petrodiesel is a fossil fuel derived from crude oil. Biodiesel has higher viscosity and lower energy density than petrodiesel.

- Combustion Characteristics: Biodiesel engines have different combustion timing and injection strategies due to the different fuel properties. Biodiesel burns with a more diffuse and elongated flame, leading to reduced soot and particulate matter emissions.

- Emission Profiles: Biodiesel engines generally produce lower carbon monoxide, particulate matter, and hydrocarbons emissions compared to petrodiesel engines. However, they may emit higher levels of nitrogen oxides (NOx) due to the higher combustion temperatures.

2. Explain the role of esterification and transesterification in biodiesel production and compare the advantages and disadvantages of each process.

- Converts free fatty acids in vegetable oils or animal fats into methyl esters using an alcohol (e.g., methanol) and a catalyst.

- Advantages: Suitable for low-quality feedstocks with high free fatty acid content.

- Disadvantages: Requires high temperatures, pressure, and longer reaction times.

- Converts triglycerides in vegetable oils or animal fats into methyl esters using an alcohol and a catalyst.

- Advantages: More efficient and faster than esterification, produces higher yields.

- Disadvantages: Requires high-quality feedstocks with low free fatty acid content.

Esterification

Transesterification

3. How do you optimize the performance of a biodiesel engine by adjusting injection timing and fuel injection parameters?

- Injection Timing: Advancing injection timing can reduce NOx emissions and particulate matter formation, but may increase hydrocarbon emissions.

- Fuel Injection Parameters: Adjusting injection pressure, spray angle, and injection duration can optimize combustion efficiency, reduce emissions, and improve fuel consumption.

- Optimization involves testing different parameters, analyzing engine data, and adjusting parameters accordingly to achieve the desired performance objectives.

4. Describe the methods used to control and minimize NOx emissions in biodiesel engines.

- Exhaust Gas Recirculation (EGR): Recirculates a portion of exhaust gases into the intake manifold to reduce combustion temperatures, thereby reducing NOx formation.

- Selective Catalytic Reduction (SCR): Injects urea solution into the exhaust system to convert NOx into harmless nitrogen and water.

- Lean Burn Combustion: Optimizes air-to-fuel ratios to reduce combustion temperatures and NOx emissions.

5. How do you troubleshoot and diagnose common problems that may arise in biodiesel engines, such as fuel injector clogging or engine knocking?

- Fuel Injector Clogging: Check fuel quality, inspect injector components, clean or replace injectors as necessary.

- Engine Knocking: Examine engine compression, ignition timing, fuel quality, and air-to-fuel ratio to identify and resolve the underlying cause.

- Troubleshooting involves using diagnostic tools, analyzing engine data, and applying knowledge of biodiesel engine systems.

6. Discuss the challenges and opportunities associated with the use of biodiesel in transportation.

- Higher production costs compared to petrodiesel.

- Cold weather operability issues.

- Limited availability of high-quality feedstocks.

- Reduced greenhouse gas emissions.

- Improved air quality.

- Potential for job creation in the biofuel industry.

Challenges

Opportunities

7. Explain the role of artificial intelligence (AI) and machine learning (ML) in optimizing biodiesel engine performance and emissions.

- AI and ML algorithms can analyze large amounts of engine data to identify patterns and optimize engine parameters.

- Predictive maintenance models can be developed to identify potential problems and schedule maintenance accordingly.

- AI-powered control systems can adjust injection timing, fuel injection parameters, and emissions control strategies in real-time to improve performance.

8. Describe the methods used to determine the cetane number and biodiesel content of biodiesel fuels.

- ASTM D613:** Measures the ignition delay of a fuel by comparing it to reference fuels with known cetane numbers.

- ASTM D6584:** Uses nuclear magnetic resonance (NMR) to determine the percentage of biodiesel in a blend with petrodiesel.

- ASTM D7371:** Uses high-performance liquid chromatography (HPLC) to quantify the different fatty acids present in biodiesel.

Cetane Number

Biodiesel Content

9. How do you ensure the quality and consistency of biodiesel fuels produced in a production plant?

- Implement strict quality control measures throughout the production process.

- Regularly analyze feedstocks and finished products to ensure compliance with specifications.

- Maintain proper storage and handling practices to prevent contamination and degradation.

10. Discuss the future trends and developments in the biodiesel industry.

- Development of more efficient and sustainable feedstocks.

- Advancements in engine technologies to further improve performance and reduce emissions.

- Integration of AI and ML for engine optimization and fuel quality control.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Biodiesel Engine Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Biodiesel Engine Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Biodiesel Engine Specialists are responsible for the maintenance, repair, and operation of biodiesel engines. They must have a strong understanding of the principles of biodiesel engine operation, as well as the ability to troubleshoot and resolve problems.

1. Engine Maintenance and Repair

Biodiesel Engine Specialists are responsible for the routine maintenance and repair of biodiesel engines. This includes tasks such as:

- Changing oil and filters

- Inspecting and cleaning engine components

- Making minor repairs, such as replacing spark plugs or belts

2. Engine Troubleshooting

Biodiesel Engine Specialists must be able to troubleshoot and resolve problems with biodiesel engines. This requires a deep understanding of the engine’s operating principles, as well as the ability to use diagnostic tools to identify and resolve problems.

3. Engine Operation

Biodiesel Engine Specialists are responsible for the safe and efficient operation of biodiesel engines. This includes tasks such as:

- Starting and stopping the engine

- Monitoring engine performance

- Adjusting engine controls to optimize performance

4. Other Responsibilities

In addition to the above, Biodiesel Engine Specialists may also be responsible for:

- Providing training to other employees on the operation and maintenance of biodiesel engines

- Participating in the development and implementation of biodiesel engine maintenance and repair programs

- Staying up-to-date on the latest biodiesel engine technologies

Interview Tips

Preparing for an interview can be stressful, but there are some things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Biodiesel Engine Specialist position:

1. Research the company and the position

Before you go on your interview, take some time to learn about the company and the specific position you are applying for. This will help you answer questions intelligently and show the interviewer that you are interested in the job.

2. Practice answering common interview questions

There are a few common interview questions that you can expect to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice answering these questions ahead of time so that you can deliver your answers confidently and concisely.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience working with biodiesel engines. Be prepared to discuss your skills and knowledge, and how you have used them to troubleshoot and resolve problems.

4. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or other business attire.

5. Be confident

Confidence is key in any interview. Believe in yourself and your abilities, and let the interviewer know that you are the best person for the job.

6. Ask questions

At the end of the interview, be sure to ask the interviewer any questions you have about the position or the company. This shows that you are engaged and interested, and it gives you a chance to learn more about the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Biodiesel Engine Specialist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.