Feeling lost in a sea of interview questions? Landed that dream interview for Biodiesel Plant Operations Engineer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Biodiesel Plant Operations Engineer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

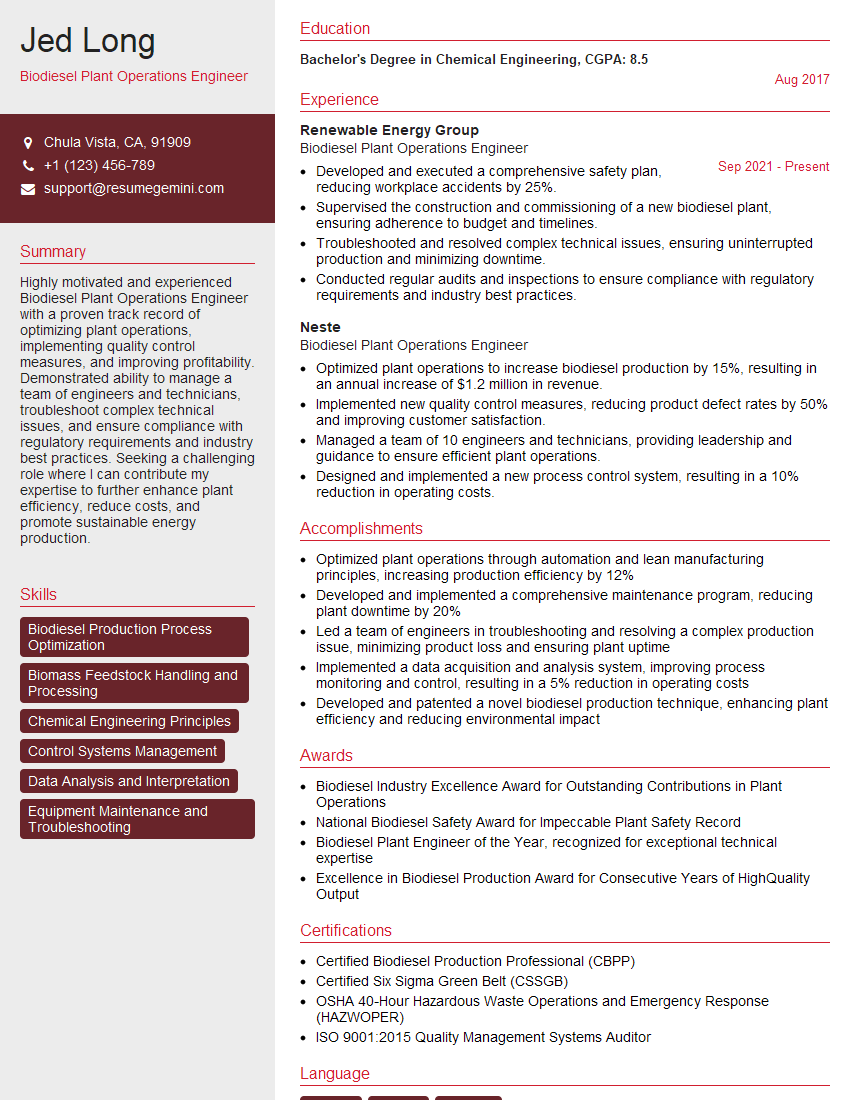

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Biodiesel Plant Operations Engineer

1. How would you optimize the biodiesel production process to maximize yield and minimize waste?

- Assess current process and identify areas for improvement.

- Implement advanced technology, such as automated control systems and data analytics.

- Optimize feedstock preparation, reactor conditions, and catalyst utilization.

- Implement efficient waste management practices, including recycling and by-product valorization.

- Conduct regular process audits and make data-driven adjustments to enhance efficiency.

2. What strategies would you employ to maintain the quality and stability of biodiesel throughout its production, storage, and distribution?

Quality Control:

- Establish strict quality standards for raw materials, intermediates, and final product.

- Implement robust testing methods and quality assurance protocols at all stages.

- Monitor process parameters to ensure compliance and identify potential deviations.

- Regularly calibrate and maintain analytical equipment for accurate results.

Stability:

- Utilize appropriate storage vessels and conditions to prevent degradation.

- Add antioxidants and other stabilizers to extend shelf life.

- Implement proper blending and transportation procedures to minimize contamination.

- Monitor biodiesel properties periodically to detect any changes that may impact stability.

3. How would you troubleshoot and resolve common operational issues that may arise in a biodiesel plant?

- Develop a comprehensive troubleshooting guide based on experience and industry best practices.

- Use analytical techniques to identify the root cause of problems.

- Implement corrective actions and follow up on their effectiveness.

- Collaborate with equipment manufacturers and technical experts for support.

- Maintain detailed records of troubleshooting efforts for future reference.

4. What maintenance practices would you implement to ensure the optimal performance and longevity of plant equipment and infrastructure?

- Establish a comprehensive maintenance schedule based on manufacturer recommendations and industry standards.

- Conduct regular inspections, cleaning, and lubrication of equipment.

- Implement condition monitoring systems to detect potential issues early.

- Train maintenance personnel on equipment operation, troubleshooting, and repair techniques.

- Maintain a spare parts inventory to minimize downtime in case of emergencies.

5. How would you manage the safety and environmental compliance of a biodiesel production facility?

Safety:

- Establish and enforce strict safety protocols, including training, PPE usage, and emergency procedures.

- Conduct regular safety audits and inspections to identify potential hazards.

- Implement engineering controls, such as ventilation and explosion protection systems.

- Maintain a positive safety culture and promote employee engagement in safety initiatives.

Environmental Compliance:

- Obtain and maintain all necessary environmental permits and licenses.

- Monitor and control emissions to meet regulatory standards.

- Implement waste minimization and recycling programs.

- Conduct regular environmental audits to ensure compliance and identify areas for improvement.

6. How would you collaborate with other departments, such as production, engineering, and quality control, to ensure the smooth operation of the plant and meet production targets?

- Establish clear lines of communication and regular meetings to coordinate activities.

- Participate in cross-functional problem-solving and decision-making processes.

- Provide technical expertise and support to other departments as needed.

- Share information and data to facilitate coordination and optimize plant performance.

- Foster a collaborative and supportive work environment to promote teamwork.

7. How would you manage the day-to-day operations of a biodiesel plant, including personnel, scheduling, and production targets?

- Develop and implement an operational plan that outlines responsibilities, schedules, and performance metrics.

- Assign tasks, train and supervise staff, and ensure compliance with safety protocols.

- Monitor production progress, identify bottlenecks, and make timely adjustments.

- Maintain communication with senior management and provide regular updates on plant performance.

- Stay up-to-date with industry best practices and implement improvements to enhance efficiency.

8. What experience do you have in optimizing energy efficiency and reducing carbon emissions in biodiesel production?

- Experience in implementing energy conservation measures, such as process optimization and equipment upgrades.

- Knowledge of renewable energy sources and their integration into biodiesel production.

- Experience in conducting energy audits and developing sustainability initiatives.

- Understanding of carbon footprint analysis and greenhouse gas mitigation strategies.

9. How would you evaluate the economic viability of biodiesel production and identify opportunities for cost optimization?

- Conduct cost-benefit analysis to assess the financial feasibility of biodiesel production.

- Identify areas for cost reduction, such as raw material sourcing, energy consumption, and waste management.

- Explore government incentives, tax credits, and other financial support programs.

- Benchmark against industry leaders and implement best practices to improve profitability.

10. How do you stay updated with the latest advancements and trends in the biodiesel industry?

- Attend industry conferences, workshops, and trade shows.

- Read technical journals and research papers related to biodiesel production.

- Network with experts in the field and collaborate on research projects.

- Monitor industry news and developments through trade publications and online resources.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Biodiesel Plant Operations Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Biodiesel Plant Operations Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Biodiesel Plant Operations Engineer is accountable for overseeing and managing the efficient operation of a biodiesel production facility. To excel in this role, a candidate should possess expertise in chemical engineering principles, process control, and plant operations management.

1. Production Management

The engineer is responsible for planning, scheduling, and monitoring the production process to ensure smooth operation and meet production targets.

- Develop and implement production plans to optimize efficiency and minimize downtime.

- Monitor production processes, identify bottlenecks, and implement corrective actions to maximize output.

2. Equipment Maintenance and Troubleshooting

The engineer is responsible for maintaining and troubleshooting equipment to prevent breakdowns and ensure optimal performance.

- Perform routine maintenance and inspections on equipment, including pumps, reactors, and separators.

- Troubleshoot and repair equipment malfunctions to minimize downtime and maintain production efficiency.

3. Process Optimization

The engineer is responsible for optimizing the production process to improve efficiency, reduce costs, and meet quality standards.

- Analyze production data, identify areas for improvement, and implement process modifications to enhance efficiency.

- Conduct experiments and pilot studies to test new technologies and improve process parameters.

4. Environmental Compliance

The engineer is responsible for ensuring compliance with environmental regulations and minimizing the environmental impact of the plant.

- Monitor emissions and waste streams to ensure compliance with environmental regulations.

- Implement pollution control measures and waste minimization strategies.

Interview Tips

To ace the interview for a Biodiesel Plant Operations Engineer position, candidates should prepare thoroughly and highlight their relevant skills and experience. Here are some tips to help you succeed:

1. Research the Company and Industry

Gather information about the company, its operations, and the biodiesel industry. This will demonstrate your interest in the position and help you answer questions intelligently.

- Visit the company website to learn about its history, mission, and products.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivations. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples.

- Tell me about a time you successfully optimized a production process.

- Describe your experience with troubleshooting and repairing equipment.

3. Highlight Your Technical Skills

Emphasize your expertise in chemical engineering principles, process control, and plant operations management. Provide examples of projects or assignments where you applied these skills successfully.

- Discuss your knowledge of biodiesel production processes, including feedstock preparation, transesterification, and purification.

- Highlight your proficiency in using process control systems and data analysis tools.

4. Demonstrate Your Understanding of Environmental Regulations

Discuss your understanding of environmental regulations related to biodiesel production. Explain how you ensure compliance and implement pollution control measures.

- Describe your experience with monitoring emissions and waste streams.

- Explain how you implement waste minimization strategies.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Biodiesel Plant Operations Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!