Feeling lost in a sea of interview questions? Landed that dream interview for Biodiesel Process Control Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Biodiesel Process Control Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

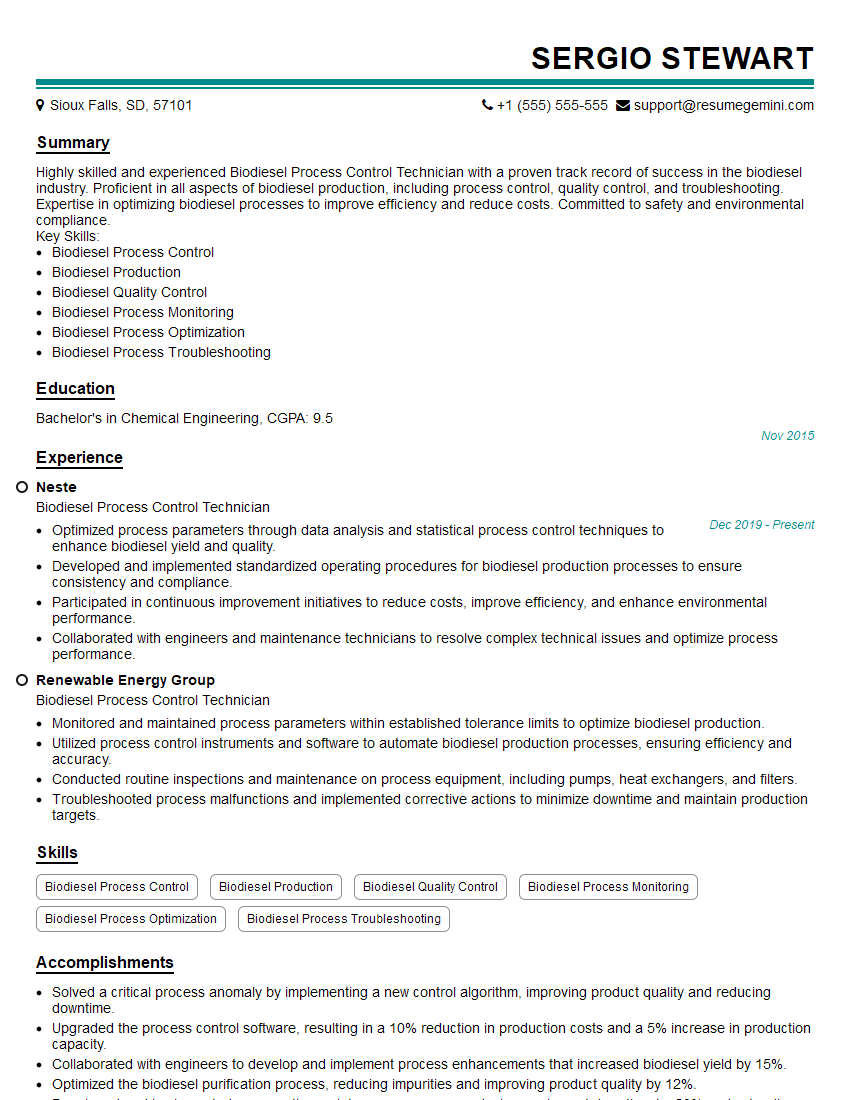

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Biodiesel Process Control Technician

1. Explain the biodiesel production process and your role as a Process Control Technician.

- The biodiesel production process involves converting vegetable oils or animal fats into fatty acid methyl esters (FAME), which is essentially biodiesel.

- My role as a Process Control Technician is to monitor and control the various parameters of the production process to ensure efficient and consistent production of biodiesel.

2. Describe the key quality control parameters in biodiesel production and how you ensure they are met.

Process Parameters

- Temperature control is crucial to maintain optimal reaction rates and prevent product degradation.

- Pressure monitoring ensures proper flow rates and prevents equipment damage.

- pH levels need to be monitored to optimize catalyst activity and prevent corrosion.

Product Parameters

- Biodiesel purity is assessed through gas chromatography to meet industry standards.

- Fatty acid profile analysis ensures the desired composition of the biodiesel.

- Water content is monitored to prevent microbial contamination and ensure product stability.

3. Discuss the different types of instrumentation used in biodiesel process control and how you interpret the data they provide.

- Temperature sensors monitor process temperature and provide feedback for control loops.

- Pressure transmitters measure pressure in the system and alert operators to potential blockages or leaks.

- pH probes monitor acidity or alkalinity, which is crucial for catalyst efficiency.

- Flow meters track the flow rate of reactants and products, allowing for adjustments to maintain optimal conditions.

- Gas chromatography provides detailed analysis of product composition, including FAME content and impurities.

4. How do you handle process deviations and ensure corrective actions are taken promptly?

- Monitor process parameters continuously and identify deviations.

- Analyze the deviation to determine the root cause.

- Implement corrective actions based on process knowledge and established procedures.

- Document the deviation, corrective actions, and results.

- Communicate with the team and supervisors to ensure coordination and follow-up.

5. Describe your experience in troubleshooting and resolving equipment issues in the biodiesel production process.

- Diagnose equipment malfunctions by analyzing symptoms, reviewing logs, and consulting technical manuals.

- Identify the root cause of the issue, considering factors such as wear and tear, process conditions, and operator error.

- Repair or replace faulty components, ensuring proper functionality and preventing further problems.

- Calibrate and maintain equipment regularly to ensure accuracy and reliability.

- Collaborate with maintenance teams to ensure timely repairs and minimize downtime.

6. How do you stay updated on the latest advancements and best practices in the biodiesel industry?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Network with professionals in the field.

- Participate in online forums and discussion groups.

- Seek professional development opportunities, such as certification programs or specialized training.

7. Describe your experience with process optimization and how you have improved the efficiency of biodiesel production.

- Analyze process data to identify areas for improvement.

- Implement process modifications, such as adjusting temperature profiles or optimizing reagent ratios.

- Monitor the effects of changes and make further adjustments as needed.

- Document and share best practices to ensure continuous improvement.

- Collaborate with engineers and chemists to explore innovative solutions and enhance process efficiency.

8. How do you ensure compliance with safety regulations and environmental standards in the biodiesel production process?

- Maintain a safe work environment by adhering to established safety protocols.

- Wear appropriate personal protective equipment (PPE).

- Handle and store chemicals safely, following proper disposal procedures.

- Monitor emissions and waste streams to comply with environmental regulations.

- Participate in safety training and drills to enhance awareness and preparedness.

9. Describe your communication and interpersonal skills in working with a team and collaborating with other departments.

- Communicate effectively with operators, supervisors, and engineers to ensure smooth operations.

- Participate in team meetings and contribute to problem-solving discussions.

- Provide technical support and guidance to other departments, such as maintenance and quality control.

- Collaborate with external vendors and contractors to ensure timely delivery and support.

- Maintain a positive and professional attitude in all interactions.

10. How do you manage your time effectively and prioritize tasks in a fast-paced production environment?

- Plan and prioritize tasks based on importance and urgency.

- Delegate responsibilities to team members to ensure efficient workload distribution.

- Use technology tools, such as work order systems and communication platforms, to streamline processes.

- Stay organized and maintain a clean and clutter-free work area.

- Communicate progress regularly to supervisors and keep them informed of any potential delays.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Biodiesel Process Control Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Biodiesel Process Control Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Biodiesel Process Control Technician is responsible for the safe and efficient operation of the biodiesel production process. Key job responsibilities include:

1. Monitoring and controlling process variables

The technician monitors and controls process variables such as temperature, pressure, flow rate, and pH to ensure that the process is operating within acceptable limits.

- Monitors process variables using instrumentation and control systems.

- Makes adjustments to process parameters to maintain optimal operating conditions.

2. Troubleshooting and resolving process problems

The technician troubleshoots and resolves process problems that may occur during production. This may involve identifying the cause of the problem, taking corrective action, and monitoring the process to ensure that the problem is resolved.

- Identifies and resolves process problems using troubleshooting techniques.

- Takes corrective action to minimize downtime and maintain product quality.

3. Maintaining and calibrating process equipment

The technician maintains and calibrates process equipment to ensure that it is operating properly. This may involve cleaning, lubricating, and adjusting equipment, as well as performing calibration checks.

- Performs preventive maintenance and calibration on process equipment.

- Ensures that equipment is operating properly to maintain product quality.

4. Conducting quality control tests

The technician conducts quality control tests on biodiesel products to ensure that they meet specifications. This may involve testing for properties such as flash point, cetane number, and viscosity.

- Conducts quality control tests on biodiesel products.

- Ensures that products meet specifications and industry standards.

Interview Tips

To prepare for an interview for a Biodiesel Process Control Technician position, it is important to:

1. Research the company and the position

Learn about the company’s mission, values, and products. Research the specific position you are applying for and identify the key responsibilities and qualifications.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Practice your answers to common interview questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses.” Practice your answers out loud to improve your delivery.

- Use the STAR method to answer interview questions.

- Situation: Describe the situation or task.

- Task: Explain your role and responsibilities.

- Action: Describe the specific actions you took.

- Results: Quantify the results of your efforts.

3. Be prepared to discuss your experience and skills

Highlight your experience and skills that are relevant to the position. Be prepared to provide specific examples of your work experience and how it has prepared you for this role.

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your experience.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Plan your route ahead of time and allow extra time for traffic or unexpected delays.

Next Step:

Now that you’re armed with the knowledge of Biodiesel Process Control Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Biodiesel Process Control Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini