Are you gearing up for an interview for a Biodiesel Processing Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Biodiesel Processing Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

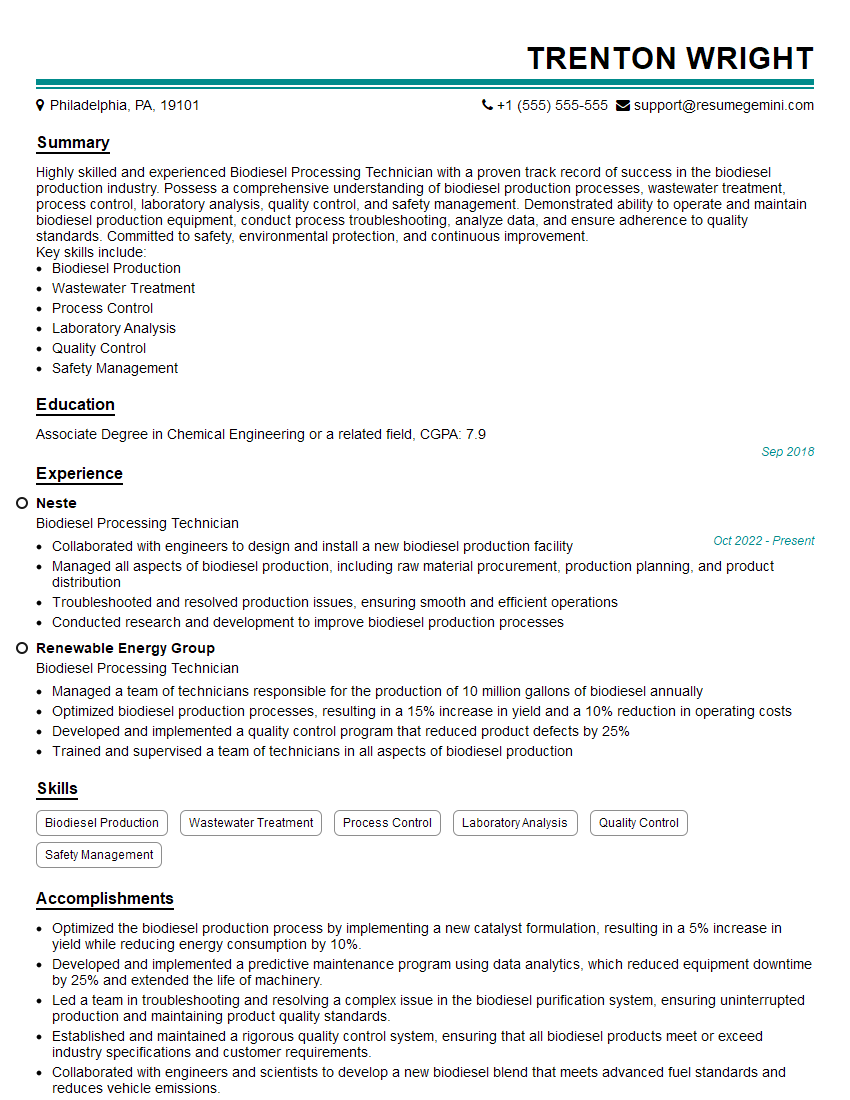

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Biodiesel Processing Technician

1. Can you explain the key steps involved in biodiesel processing?

- A. Feedstock Preparation: Selection, cleaning, and grinding of raw material (e.g., vegetable oils, animal fats, waste cooking oil).

- B. Transesterification Reaction: React feedstock with alcohol (e.g., methanol, ethanol) and a catalyst (e.g., sodium hydroxide, potassium hydroxide) to form biodiesel and glycerol.

- C. Glycerol Separation: Remove glycerol byproduct from the reaction mixture through settling, decantation, or centrifugation.

- D. Biodiesel Washing: Wash biodiesel with water to remove residual catalyst, impurities, and excess alcohol.

- E. Drying and Purification: Remove moisture and further impurities through filtration, heating, or vacuum distillation.

2. Describe the different feedstocks that can be used for biodiesel production.

Advantages of Vegetable Oils

- High oil content and good yield

- Renewable and sustainable

- Example: soybean oil, rapeseed oil, palm oil

Advantages of Animal Fats

- Lower production costs compared to vegetable oils

- Abundant source from animal processing industries

- Example: chicken fat, beef tallow

Advantages of Waste Cooking Oil

- Environmentally friendly as it recycles waste

- Cheaper than other feedstocks

- Requires pre-treatment to remove impurities

3. Explain the role of a catalyst in the transesterification reaction.

- A catalyst accelerates the transesterification reaction rate

- It provides an alternative pathway with lower activation energy

- Commonly used catalysts: sodium hydroxide (NaOH), potassium hydroxide (KOH)

- Catalyst concentration and reaction conditions affect the efficiency of the process

4. What are the quality control parameters for biodiesel and how are they measured?

- A. Acid Value (AV): Measures the acidity of biodiesel, indicating the presence of free fatty acids. Tested using ASTM D664 or EN 14104.

- B. Iodine Value (IV): Indicates the degree of unsaturation in biodiesel. Determined using ASTM D5554 or EN 14111.

- C. Cetane Number (CN): Measures the ignition quality of biodiesel. Tested according to ASTM D613 or EN 14214.

- D. Flash Point: Determines the temperature at which biodiesel vapors will ignite. Measured using ASTM D93 or EN ISO 2592.

5. Describe the safety precautions that need to be followed when working with biodiesel.

- A. Methanol is a highly flammable and toxic substance; proper ventilation and protective gear are essential.

- B. Sodium hydroxide and potassium hydroxide are corrosive; avoid skin contact and wear appropriate personal protective equipment (PPE).

- C. Biodiesel can be slippery; ensure a clean and dry work environment to prevent accidents.

- D. Follow established safety protocols and training for handling chemicals and operating equipment.

6. What is the difference between biodiesel and petrodiesel?

- A. Feedstock: Biodiesel is derived from renewable sources (e.g., vegetable oils, animal fats), while petrodiesel comes from crude oil.

- B. Production: Biodiesel is produced through transesterification, while petrodiesel undergoes refining and distillation processes.

- C. Emissions: Biodiesel generally produces lower greenhouse gas emissions compared to petrodiesel.

- D. Lubricity: Biodiesel has lower lubricity than petrodiesel, requiring additives to prevent engine wear.

7. Can you explain the importance of yield optimization in biodiesel production?

- A. Maximizing yield increases production efficiency and profitability.

- B. Factors affecting yield: feedstock quality, catalyst selection, reaction conditions (e.g., temperature, time, agitation).

- C. Optimization techniques: response surface methodology, statistical analysis, process modeling.

- D. Higher yield reduces waste generation and environmental impact.

8. Describe the role of quality control in ensuring the reliability and performance of biodiesel.

- A. Quality control ensures adherence to specifications and industry standards.

- B. Regular testing and monitoring of feedstock, intermediates, and final product.

- C. Identification and correction of deviations from quality targets.

- D. Maintains product consistency, prevents equipment damage, and ensures compliance with regulations.

9. How do you stay updated with the latest advancements and best practices in biodiesel processing technology?

- A. Attend industry conferences, workshops, and training programs.

- B. Read technical journals, articles, and research papers.

- C. Network with professionals and experts in the field.

- D. Utilize online resources and databases for information dissemination.

10. What are your strengths and weaknesses as a Biodiesel Processing Technician?

- A. In-depth knowledge of biodiesel processing principles and techniques.

- B. Proven experience in operating and maintaining biodiesel production equipment.

- C. Strong analytical and problem-solving abilities.

- D. Excellent communication and interpersonal skills.

- E. Commitment to safety and environmental stewardship.

- A. Limited experience with newer biodiesel feedstocks (e.g., algae-based oils).

- B. Seeking opportunities to enhance my knowledge of process automation and control systems.

- C. Open to constructive feedback and eager to improve my technical abilities.

Strengths:

Weaknesses:

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Biodiesel Processing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Biodiesel Processing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Biodiesel Processing Technicians are responsible for the day-to-day operations of a biodiesel production facility. They ensure that the plant is running smoothly and that the biodiesel is produced to the correct specifications. Key responsibilities include:

1. Operating and monitoring biodiesel production equipment

This involves ensuring that the equipment is running properly and that the biodiesel is being produced to the correct specifications. Technicians may also need to adjust the equipment settings or troubleshoot problems.

- Monitoring the temperature, pressure, and flow rate of the biodiesel production process

- Adjusting the equipment settings to ensure that the biodiesel is produced to the correct specifications

- Troubleshooting problems with the biodiesel production equipment

2. Testing and analyzing biodiesel samples

This involves testing the biodiesel to ensure that it meets the required specifications. Technicians may also need to analyze the biodiesel to identify any problems with the production process.

- Testing the biodiesel for its quality and compliance with industry standards

- Analyzing the biodiesel to identify any problems with the production process

- Reporting the test results to the supervisor

3. Maintaining the biodiesel production facility

This involves keeping the facility clean and in good repair. Technicians may also need to perform preventive maintenance on the equipment.

- Cleaning the biodiesel production facility

- Inspecting and maintaining the equipment

- Performing preventive maintenance on the equipment

4. Following safety procedures

This involves following all safety procedures to ensure the safety of themselves and others. Technicians may also need to train other employees on safety procedures.

- Following all safety procedures

- Training other employees on safety procedures

Interview Tips

If you are preparing for an interview for a Biodiesel Processing Technician position, there are a few things you can do to increase your chances of success. Here are some tips:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the position. You can find information about the company on its website, social media pages, and Glassdoor.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Highlight your relevant experience and skills

When you are answering interview questions, be sure to highlight your relevant experience and skills. This includes any experience you have with biodiesel production, as well as any other relevant skills, such as problem-solving, troubleshooting, and teamwork.

4. Be prepared to talk about your safety knowledge

Safety is a very important part of the biodiesel production process. Be prepared to talk about your knowledge of safety procedures and how you would ensure the safety of yourself and others in the workplace.

5. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the position. Be sure to show your enthusiasm for the biodiesel industry and your desire to learn more about the production process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Biodiesel Processing Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.