Are you gearing up for an interview for a Bisque Ware Dipper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bisque Ware Dipper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

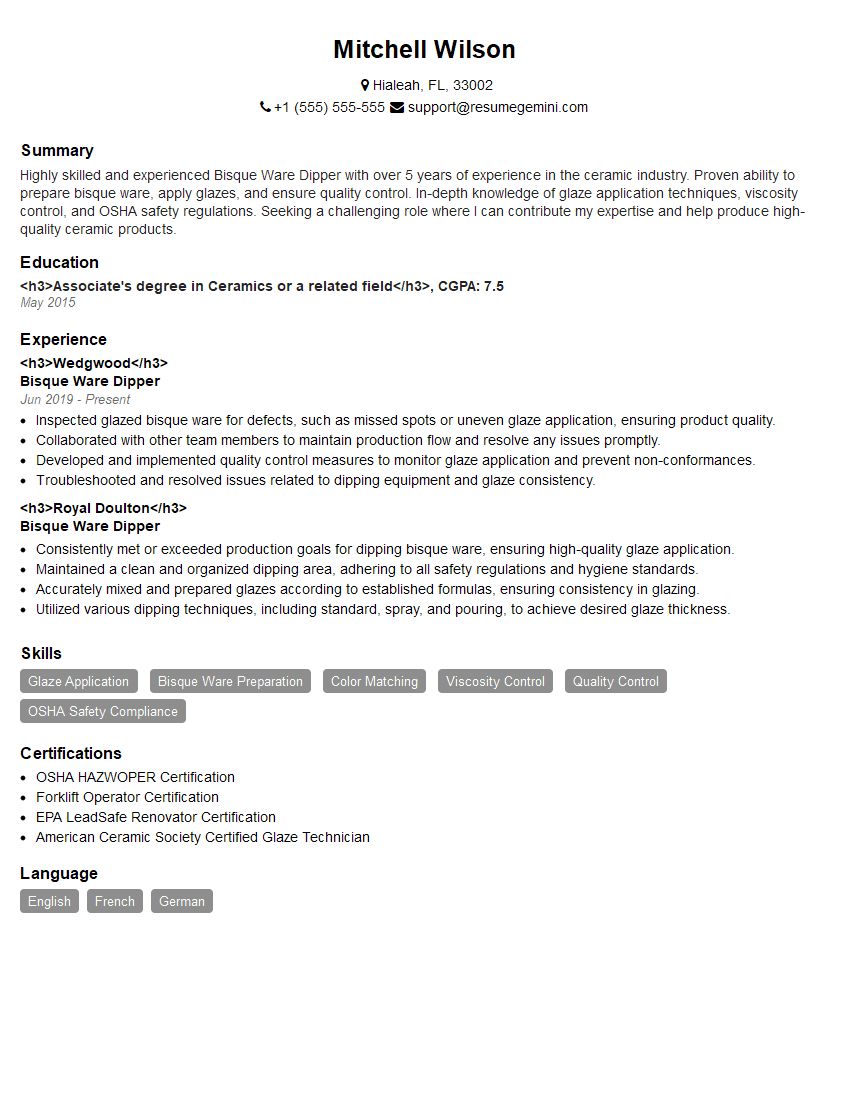

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bisque Ware Dipper

1. Describe the process of bisque firing.

Bisque firing is the first step in the firing process for ceramics. It involves heating the clay to a temperature between 1832°F (1000°C) and 2102°F (1150°C) to harden it and make it porous.

- Bisque firing removes the moisture from the clay and makes it strong enough to handle.

- It also creates a porous surface that allows glazes to adhere properly.

2. What are the different types of glazes used in bisque firing?

Lead-based glazes

- Lead-based glazes are the most common type of glaze used in bisque firing.

- They are easy to apply and produce a glossy finish.

- However, they are toxic and should not be used on foodware.

Non-lead glazes

- Non-lead glazes are a safer alternative to lead-based glazes.

- They produce a variety of finishes, including matte, satin, and glossy.

3. What are the factors that can affect the outcome of bisque firing?

- The type of clay used

- The thickness of the clay

- The temperature of the kiln

- The length of time the clay is fired

- The atmosphere in the kiln

4. What are the common defects that can occur during bisque firing?

- Crazing

- Warping

- Bloating

- Pitting

- Blistering

5. How can you troubleshoot bisque firing defects?

- Crazing can be caused by using too much glaze or firing the clay too quickly.

- Warping can be caused by uneven heating or using too thin of a clay.

- Bloating can be caused by using too much organic matter in the clay or firing the clay too slowly.

- Pitting can be caused by using too little glaze or firing the clay too quickly.

- Blistering can be caused by using too much glaze or firing the clay too quickly.

6. What is the role of a bisque ware dipper?

- A bisque ware dipper is responsible for applying glaze to bisque-fired ceramics.

- They use a variety of techniques to apply glaze, including dipping, pouring, and spraying.

- Bisque ware dippers must have a good understanding of the different types of glazes and how to apply them properly.

7. What are the qualities of a good bisque ware dipper?

- Attention to detail

- Patience

- Dexterity

- Knowledge of glazes

- Ability to work independently

8. What are the challenges of being a bisque ware dipper?

- The work can be repetitive and tedious.

- The chemicals used in glazes can be harmful if not handled properly.

- The work can be physically demanding, as dippers often have to stand for long periods of time.

9. What is your favorite thing about being a bisque ware dipper?

I enjoy the creative aspect of the job. I like being able to see my work come to life and to know that I am helping to create beautiful pieces of art.

10. What are your career goals?

I would like to continue to develop my skills as a bisque ware dipper and to eventually become a master dipper. I would also like to learn more about the different types of glazes and how to use them to create different effects.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bisque Ware Dipper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bisque Ware Dipper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Bisque Ware Dipper, your primary responsibility is to ensure the smooth and efficient operation of the dipping process in a ceramics manufacturing facility.

1. Prepare Glaze Suspensions

You will be responsible for preparing glaze suspensions by mixing raw materials, such as clays, minerals, and water, according to specified recipes.

- Accurately weigh and measure ingredients to achieve precise glaze formulations.

- Monitor glaze viscosity and pH levels to ensure optimal dipping conditions.

2. Dip Bisque Ware

You will manually or mechanically dip bisque ware (unfired ceramic pieces) into the prepared glaze suspensions.

- Immerse the ware in the glaze, ensuring complete coverage without drips or runs.

- Control the dipping time and withdrawal speed to achieve desired glaze thickness.

3. Inspect Dipped Ware

After dipping, you will inspect the glazed ware for any defects, such as bubbles, cracks, or uneven glaze distribution.

- Identify and remove defective pieces to maintain product quality.

- Touch up or re-dip ware as necessary to correct minor flaws.

4. Optimize Dipping Process

You will regularly evaluate and adjust the dipping process to improve efficiency and minimize waste.

- Test glaze formulations and dipping techniques to identify optimal parameters.

- Implement process improvements to reduce glaze consumption and enhance ware quality.

Interview Tips

To prepare for your Bisque Ware Dipper interview, follow these tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, culture, and products to demonstrate your interest and understanding.

- Visit the company website and read industry news to gain insights.

- Prepare questions to ask the interviewer about the company and role, showing your engagement.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in glaze preparation, dipping techniques, and quality control procedures.

- Quantify your experience, providing specific examples of glaze formulations you have developed or production efficiencies you have implemented.

- Showcase your attention to detail and ability to work independently and as part of a team.

3. Practice Answering Common Interview Questions

Anticipate questions about your experience, skills, and motivations for applying for the role.

- Prepare examples that demonstrate your technical expertise, problem-solving abilities, and commitment to quality.

- Consider hypothetical scenarios that may arise in a dipping operation and how you would approach them.

4. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Maintain eye contact, speak clearly, and engage actively with the interviewer.

- Demonstrate your enthusiasm for the role and the ceramics industry.

- Express your willingness to learn and contribute to the team’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bisque Ware Dipper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!