Are you gearing up for a career in Bit and Shank Department Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bit and Shank Department Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

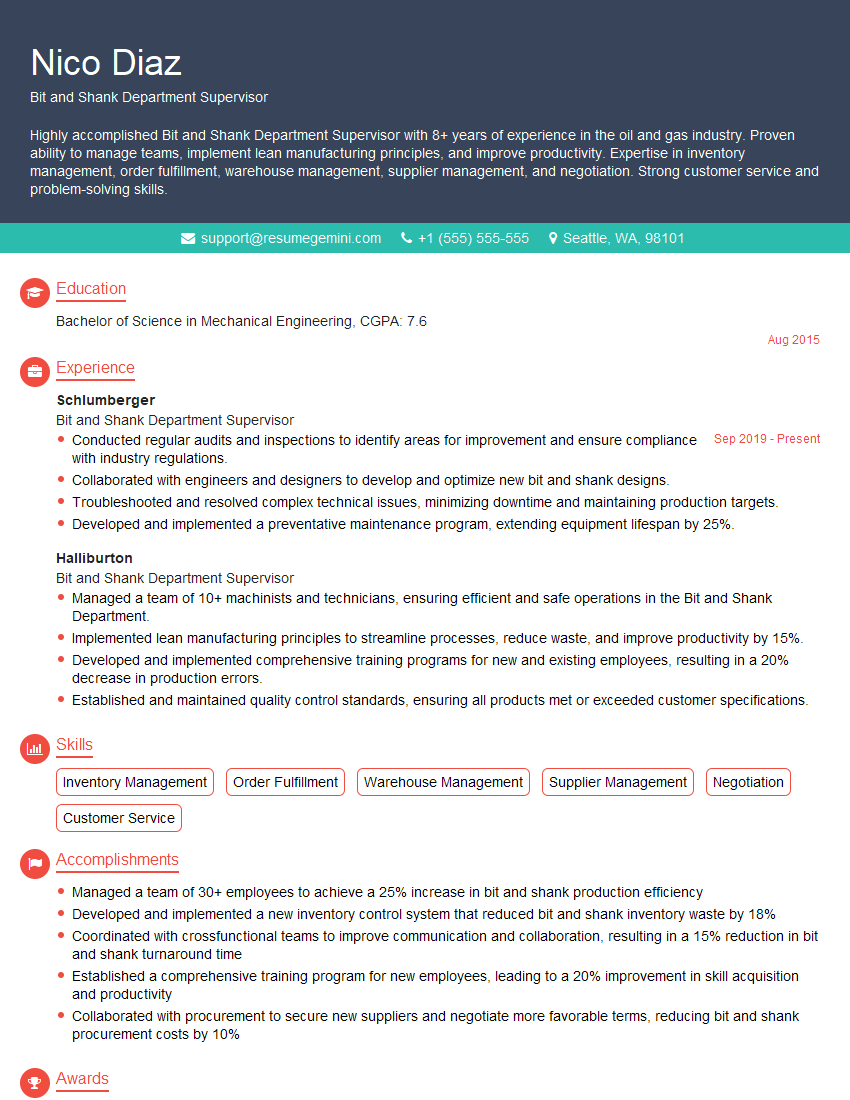

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bit and Shank Department Supervisor

1. What are the key responsibilities of a Bit and Shank Department Supervisor?

As a Bit and Shank Department Supervisor, I would be responsible for:

- Supervising and managing the department’s operations, including production, quality control, and inventory management.

- Developing and implementing production schedules to meet customer demand.

- Ensuring that all products meet the company’s quality standards.

- Managing inventory levels and ensuring that the department is always stocked with the necessary materials.

- Training and developing staff to ensure that they have the skills and knowledge to perform their jobs effectively.

2. Describe the process of manufacturing bits and shanks.

Material Procurement

- Determine the type and quantity of raw materials needed.

- Source and purchase materials from approved suppliers.

Production Planning

- Develop production schedules based on customer orders and inventory levels.

- Assign tasks and responsibilities to team members.

Manufacturing

- Forge, grind, and heat treat bits and shanks to specifications.

- Conduct quality control inspections throughout the process.

Finishing

- Apply coatings and finishes to bits and shanks.

- Package and label finished products.

Quality Control

- Implement and maintain quality control standards.

- Inspect products at various stages of production.

3. What are the different types of bits and shanks used in manufacturing?

- Twist drills

- Drill bits

- Milling cutters

- Taps

- Dies

- Counterbores

- Countersinks

4. What are the key factors to consider when selecting the right type of bit or shank for a particular application?

- Material being machined

- Type of operation (drilling, milling, tapping, etc.)

- Hole size and depth

- Machine tool being used

- Desired accuracy and finish

5. What are the safety precautions that must be observed when working with bits and shanks?

- Always wear appropriate safety gear, including eye protection, gloves, and hearing protection.

- Never use a bit or shank that is damaged or worn.

- Securely clamp the workpiece before starting any operation.

- Be aware of the machine’s rotation and never place your hands or fingers near the cutting area.

- Never attempt to remove a bit or shank from the machine while it is running.

6. What are the most common problems that can occur when using bits and shanks?

- Breakage

- Wear

- Overheating

- Vibration

- Poor surface finish

7. How do you troubleshoot and resolve problems with bits and shanks?

- Identify the cause of the problem.

- Select the appropriate solution.

- Implement the solution.

- Verify that the problem has been resolved.

8. What are the latest trends in bit and shank technology?

- Development of new materials

- Improved coatings

- New cutting geometries

- Advanced manufacturing techniques

9. What is your experience with lean manufacturing principles?

I have experience with lean manufacturing principles and have implemented them in previous roles. I believe that lean manufacturing is a valuable tool that can help to improve efficiency, reduce waste, and increase productivity. I am familiar with the 5S system, kaizen, and other lean tools and techniques.

10. What is your leadership style?

I am a collaborative and empowering leader. I believe that my team is my most valuable asset, and I strive to create an environment where they can succeed. I am always willing to listen to new ideas and suggestions, and I encourage my team to take ownership of their work. I am also a strong believer in continuous improvement, and I am always looking for ways to improve my leadership skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bit and Shank Department Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bit and Shank Department Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Bit and Shank Department Supervisor is responsible for managing all aspects of the department, including production, quality control, and safety. This individual must have a strong understanding of bit and shank manufacturing processes, as well as a proven track record of success in a manufacturing environment.

1. Production Management

The supervisor is responsible for planning and coordinating the production schedule, ensuring that all orders are completed on time and within budget. This includes working with customers to track progress and resolve any issues that may arise.

- Develops and implements production plans

- Monitors production progress and takes corrective action as needed

- Coordinates with other departments to ensure that materials and equipment are available

2. Quality Control

The supervisor is responsible for ensuring that all products meet the required quality standards. This includes inspecting products at all stages of the manufacturing process, as well as conducting audits to identify and correct any potential quality issues.

- Develops and implements quality control procedures

- Inspects products and takes corrective action as needed

- Conducts audits to identify and correct quality issues

3. Safety

The supervisor is responsible for ensuring that the workplace is safe for all employees. This includes conducting safety inspections, training employees on safety procedures, and investigating any accidents or injuries that may occur.

- Develops and implements safety procedures

- Conducts safety inspections and takes corrective action as needed

- Investigates accidents and injuries and takes corrective action to prevent future incidents

4. Employee Management

The supervisor is responsible for managing a team of employees. This includes hiring, training, and evaluating employees, as well as providing feedback and coaching to improve performance.

- Hires, trains, and evaluates employees

- Provides feedback and coaching to improve performance

- Disciplines employees as needed

Interview Tips

Here are some tips to help you ace your interview for a Bit and Shank Department Supervisor position:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities of the position.

2. Prepare your answers to common interview questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Highlight your relevant experience and skills

In your interview, make sure to highlight your relevant experience and skills that make you a good fit for the position. For example, if you have experience in production management, quality control, or safety, be sure to mention this in your answers.

4. Be enthusiastic and professional

First impressions matter, so be sure to be enthusiastic and professional in your interview. Dress appropriately, arrive on time, and make eye contact with the interviewer. Throughout the interview, maintain a positive attitude and show that you are interested in the position.

5. Follow up

After your interview, be sure to follow up with the interviewer. This could include sending a thank-you note or email, or calling the interviewer to reiterate your interest in the position. This shows that you are genuinely interested in the position and that you are willing to go the extra mile.

Next Step:

Now that you’re armed with the knowledge of Bit and Shank Department Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bit and Shank Department Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini