Feeling lost in a sea of interview questions? Landed that dream interview for Bit Sharpener Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bit Sharpener Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

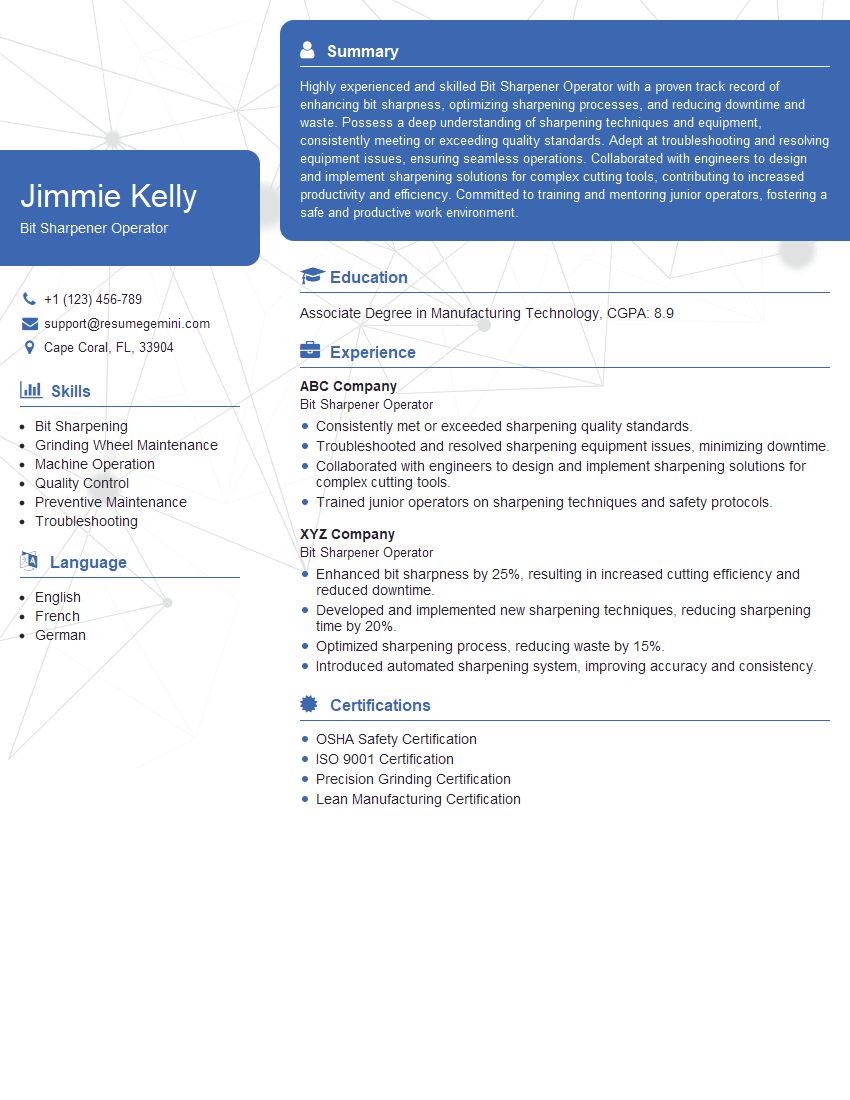

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bit Sharpener Operator

1. Describe the process of sharpening a drill bit.

- Inspect the bit for damage or wear.

- Select the appropriate grinding wheel.

- Position the bit on the grinding wheel and hold it securely.

- Grind the bit until it is sharp.

- Inspect the bit for sharpness and make adjustments as needed.

2. What are the different types of drill bits?

Twist drills

- Most common type of drill bit.

- Used for drilling holes in a variety of materials.

- Available in a variety of sizes and shapes.

Spade bits

- Used for drilling large holes in wood.

- Have a flat, spade-shaped head.

- Available in a variety of sizes.

Forstner bits

- Used for drilling flat-bottomed holes in wood.

- Have a sharp cutting edge and a flat bottom.

- Available in a variety of sizes.

3. What are the safety precautions that must be taken when sharpening drill bits?

- Wear safety glasses.

- Wear gloves.

- Ensure that the grinding wheel is properly guarded.

- Do not overspeed the grinding wheel.

- Use a light touch when grinding.

4. How do you determine the correct angle for sharpening a drill bit?

- The correct angle for sharpening a drill bit depends on the type of material you are drilling.

- For general purpose drilling, a 118-degree angle is a good starting point.

- For drilling harder materials, a 135-degree angle may be necessary.

- For drilling softer materials, a 90-degree angle may be sufficient.

5. What are the signs that a drill bit is dull?

- Difficulty drilling through material.

- Excessive heat build-up.

- Blunt or rounded cutting edges.

- Wear on the drill bit’s flutes.

6. What is the best way to store drill bits?

- Store drill bits in a dry place.

- Use a drill bit organizer to keep drill bits from getting lost or damaged.

- Do not store drill bits in a tool box with other tools that could damage them.

7. What are some tips for sharpening drill bits?

- Use a sharp grinding wheel.

- Hold the drill bit steady and at the correct angle.

- Grind the bit slowly and evenly.

- Check the bit frequently for sharpness.

- Do not over-grind the bit.

8. What are some common mistakes that people make when sharpening drill bits?

- Using a dull grinding wheel.

- Holding the drill bit at the wrong angle.

- Grinding the bit too quickly or unevenly.

- Not checking the bit frequently for sharpness.

- Over-grinding the bit.

9. What are the different types of grinding wheels that can be used to sharpen drill bits?

Diamond grinding wheels

- Most expensive type of grinding wheel.

- Lasts longer than other types of grinding wheels.

- Provides a very sharp edge.

CBN grinding wheels

- Less expensive than diamond grinding wheels.

- Provides a good sharp edge.

- Lasts longer than aluminum oxide grinding wheels.

Aluminum oxide grinding wheels

- Least expensive type of grinding wheel.

- Provides a good sharp edge.

- Wears out quickly.

10. What are the advantages of using a drill bit sharpener?

- Drill bits sharpeners can quickly and easily sharpen drill bits.

- Drill bit sharpeners can help to improve the performance of drill bits.

- Drill bit sharpeners can help to extend the life of drill bits.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bit Sharpener Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bit Sharpener Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Bit Sharpener Operator, you will be responsible for maintaining and sharpening cutting tools used in various industrial and manufacturing processes. Your duties will include:

1. Sharpening and Grinding

Inspect cutting tools for wear and damage, and determine the appropriate sharpening or grinding method

- Set up and operate grinding machines to sharpen or grind tools according to specifications

- Monitor grinding processes and make adjustments as necessary to ensure optimal performance

2. Tool Calibration and Inspection

Calibrate and inspect sharpened tools to ensure they meet required tolerances and specifications

- Use precision measuring instruments to check tool dimensions and angles

- Identify and correct any deviations from specifications

3. Equipment Maintenance

Perform routine maintenance and repairs on grinding machines and other equipment used in the sharpening process

- Lubricate, clean, and adjust machines to ensure proper operation

- Identify and troubleshoot equipment problems to avoid costly downtime

4. Safety Compliance

Adhere to all safety regulations and guidelines to ensure a safe working environment

- Wear appropriate personal protective equipment (PPE)

- Follow proper machine operating procedures and lockout/tagout protocols

Interview Tips

To ace your interview for a Bit Sharpener Operator position, follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends to demonstrate your knowledge and interest in the role.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on the latest technologies and practices

2. Prepare for Technical Questions

Expect questions related to your experience with grinding machines, tool calibration, and safety protocols. To prepare:

- Review your knowledge of sharpening techniques and equipment

- Practice describing your troubleshooting and problem-solving skills

3. Highlight Your Safety Consciousness

Emphasize your commitment to safety by mentioning your compliance with PPE regulations and understanding of lockout/tagout procedures.

- Provide examples of how you have promoted safety in previous work environments

- Explain your understanding of the importance of following safety protocols

4. Showcase Your Attention to Detail

Qualities such as precision and accuracy are crucial for this role. Highlight your ability to work with precise measurements and your commitment to meeting high standards.

- Describe your experience with using precision measuring instruments and maintaining tight tolerances

- Emphasize your willingness to double-check your work and ensure accuracy

Next Step:

Now that you’re armed with the knowledge of Bit Sharpener Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Bit Sharpener Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini