Feeling lost in a sea of interview questions? Landed that dream interview for Bit Welder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bit Welder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

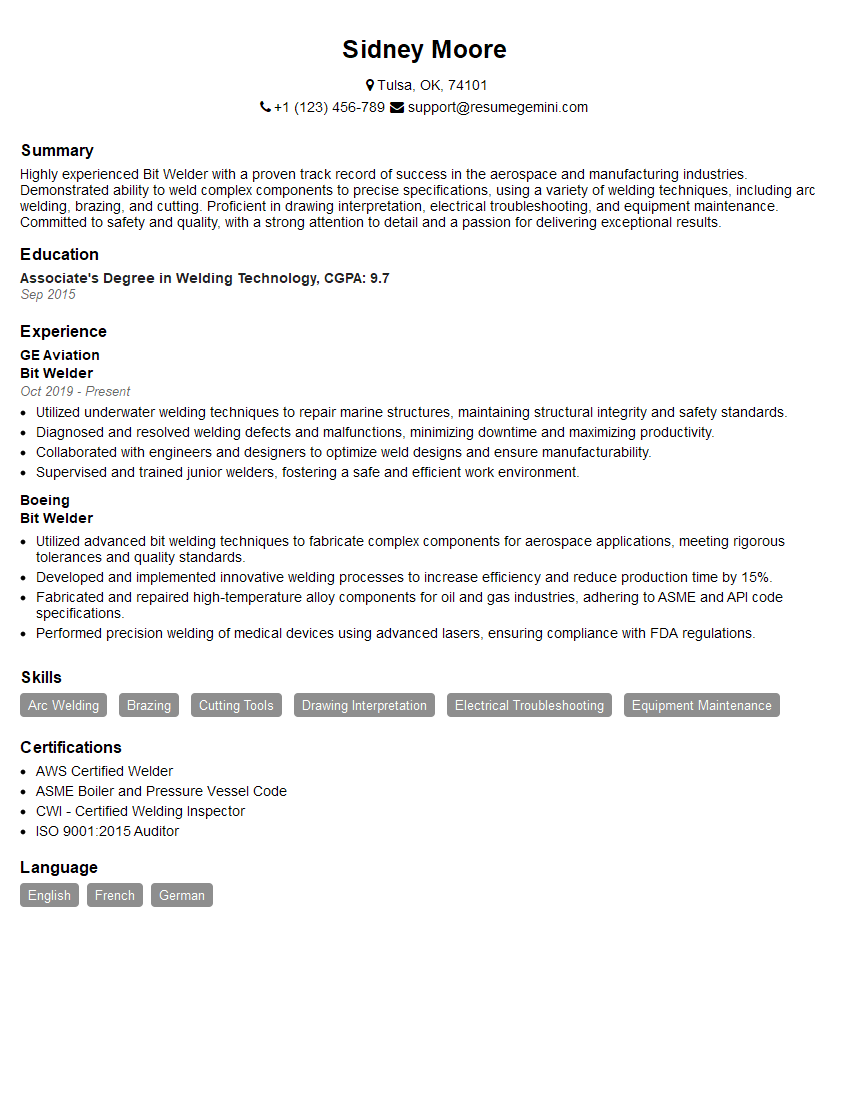

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bit Welder

1. Describe your experience with different welding techniques.

In my previous role, I gained proficiency in a range of welding techniques, including arc welding, MIG welding, TIG welding, and gas welding. I have experience working with various materials such as carbon steel, stainless steel, and aluminum.

- Arc welding: I am familiar with different types of arc welding processes, including SMAW (Shielded Metal Arc Welding), FCAW (Flux-Cored Arc Welding), and GTAW (Gas Tungsten Arc Welding).

- MIG welding: I have experience in both manual and robotic MIG welding, using various shielding gases and consumables.

- TIG welding: I am proficient in TIG welding, which involves using a non-consumable tungsten electrode to create high-quality welds.

- Gas welding: I have experience in gas welding, which involves using a fuel gas (such as acetylene or propane) and oxygen to create a flame for welding.

2. Explain the welding process for a critical component.

Material preparation

- Cut the material to the desired shape and dimensions.

- Clean the material to remove any dirt, grease, or oxidation.

- Bevel the edges of the material to prepare for welding.

Welding

- Select the appropriate welding technique and parameters.

- Tack weld the pieces together to hold them in place.

- Weld the pieces together using a continuous or intermittent welding motion.

- Cool the weldment slowly to minimize distortion and improve strength.

Inspection and testing

- Visually inspect the weldment for any defects.

- Perform non-destructive testing (NDT) to assess the weld quality, such as radiography or ultrasonic testing.

3. Describe your experience with welding safety procedures.

I am well-versed in welding safety procedures and always prioritize safety in my work. I wear appropriate personal protective equipment (PPE), including a welding helmet, gloves, and protective clothing, to minimize exposure to hazardous materials and radiation.

- Proper ventilation: I ensure adequate ventilation in the welding area to prevent the accumulation of welding fumes and gases.

- Fire safety: I keep a fire extinguisher nearby and am trained in fire prevention and suppression techniques.

- Electrical safety: I inspect and maintain welding equipment regularly to prevent electrical hazards.

4. Explain the importance of weld quality and how you ensure it.

Weld quality is critical to ensure the integrity and reliability of welded structures. I take several measures to ensure high-quality welds:

- Proper joint preparation: I ensure proper joint preparation, including proper fit-up, edge preparation, and cleanliness.

- Selection of appropriate welding parameters: I carefully select welding parameters, such as amperage, voltage, and travel speed, based on the material and joint design.

- Skilled welding technique: I use proper welding techniques to minimize defects and achieve optimal weld penetration and fusion.

- Inspection and testing: I perform visual inspections and non-destructive testing (NDT) to verify weld quality and identify any potential defects.

5. Describe your experience with welding inspection and testing methods.

I have experience with various welding inspection and testing methods, including:

- Visual inspection: I perform visual inspections to identify surface defects, such as cracks, porosity, and undercuts.

- Radiographic testing (RT): RT involves using X-rays or gamma rays to detect internal defects within the weld.

- Ultrasonic testing (UT): UT uses sound waves to detect internal defects and measure weld thickness.

- Magnetic particle testing (MT): MT involves applying magnetic particles to the weld to detect surface and near-surface cracks.

6. Explain how you stay up-to-date on the latest welding technologies.

I am committed to continuous learning and staying up-to-date on the latest welding technologies. I regularly attend industry conferences, workshops, and training programs to enhance my knowledge and skills.

- Technical publications: I subscribe to technical publications and journals to stay informed about new welding techniques and advancements.

- Online resources: I utilize online resources, such as webinars, online courses, and technical forums, to access the latest welding information.

- Collaboration with peers: I engage in discussions with other welders and industry professionals to exchange knowledge and learn about emerging technologies.

7. Describe your experience with welding different materials.

I have experience welding a wide range of materials, including:

- Carbon steel: I am proficient in welding carbon steel, which is commonly used in structural applications.

- Stainless steel: I have experience welding stainless steel, which is used in various industries, including food processing and medical equipment.

- Aluminum: I am familiar with welding aluminum, which requires specialized techniques due to its low melting point and high thermal conductivity.

- Exotic materials: I have also worked with exotic materials, such as titanium and Inconel, which are used in demanding applications.

8. Explain the importance of welding symbols and how you interpret them.

Welding symbols are critical for communicating welding requirements on drawings and specifications. I am well-versed in interpreting welding symbols according to industry standards, such as AWS A2.4.

- Weld type: I can identify different weld types, such as groove welds, fillet welds, and edge welds, based on the symbol.

- Weld size: I can determine the size of the weld, including the throat thickness and width, from the symbol.

- Weld location: I can interpret the location of the weld, including the joint type and the surface to be welded, from the symbol.

9. Describe your experience with welding in different positions.

I have experience welding in various positions, including:

- Flat position: I am proficient in welding in the flat position, where the work is positioned horizontally.

- Horizontal position: I am comfortable welding in the horizontal position, where the work is positioned vertically.

- Overhead position: I have experience welding in the overhead position, where the work is positioned above the welder.

- Vertical position: I can weld in the vertical position, where the work is positioned vertically and the weld is made vertically.

10. Explain how you handle welding defects and corrective actions.

Welding defects can occur during the welding process. I am familiar with common welding defects and have experience in identifying and correcting them.

- Identification: I can identify different types of welding defects, such as porosity, cracks, and undercuts, based on their appearance.

- Root cause analysis: I investigate the root cause of the defect to determine the underlying issue.

- Corrective actions: I implement appropriate corrective actions to eliminate the defect and prevent its recurrence.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bit Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bit Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bit Welders are responsible for welding bits to drill rods, ensuring the proper functioning of drilling equipment. Their primary duties involve:

1. Welding Bits

Performing manual or semi-automatic welding of drill bits to drill rods, utilizing appropriate welding techniques and equipment.

- Selecting and preparing drill bits and drill rods for welding.

- Ensuring proper alignment and positioning of components before welding.

- Operating welding equipment to fuse bits and rods together, creating strong and durable welds.

2. Inspection and Quality Control

Inspecting welded bits to ensure they meet specifications and quality standards.

- Checking welds for defects, such as cracks, porosity, or incomplete fusion.

- Conducting hardness tests to verify the quality of the welds.

- Maintaining records and documentation related to weld inspections and quality control measures.

3. Maintenance and Calibration

Performing routine maintenance and calibration of welding equipment to ensure optimal performance.

- Cleaning and inspecting welding torches, tips, and cables.

- Calibrating welding machines and equipment to ensure accurate and consistent welding results.

- Troubleshooting and resolving any equipment malfunctions or issues.

4. Safety and Compliance

Observing and adhering to all safety regulations and guidelines related to welding operations.

- Wearing appropriate personal protective equipment, such as welding helmets, gloves, and clothing.

- Following established safety protocols for handling and storing welding materials.

- Maintaining a clean and organized work area to prevent accidents.

Interview Tips

To ace an interview for a Bit Welder position, consider these preparation tips and hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s background, mission, and values. Research the industry trends and advancements related to drilling and welding.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in manual or semi-automatic welding techniques, specifically in welding drill bits to drill rods. Showcase your knowledge of welding equipment and safety procedures.

3. Demonstrate Attention to Detail

Highlight your meticulous nature and ability to follow precise instructions. Emphasize your experience in inspecting welds for defects and ensuring quality control.

4. Prepare for Technical Questions

Anticipate questions related to welding metallurgy, weld inspection techniques, and welding equipment calibration. Be prepared to discuss your understanding of these technical concepts.

5. Showcase Safety Awareness

Demonstrate your commitment to safety by discussing your experience in following safety protocols and maintaining a clean and organized work environment.

6. Be Enthusiastic and Confident

Convey your passion for welding and your eagerness to contribute to the team. Maintain a positive attitude and express your confidence in your abilities.

7. Ask Informed Questions

At the end of the interview, prepare insightful questions to ask the interviewer. This shows your interest in the position and the company.

8. Practice Your Answers

Rehearse your responses to common interview questions to improve your delivery and confidence. Consider seeking feedback from a mentor or career counselor.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bit Welder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.