Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blacksmith position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

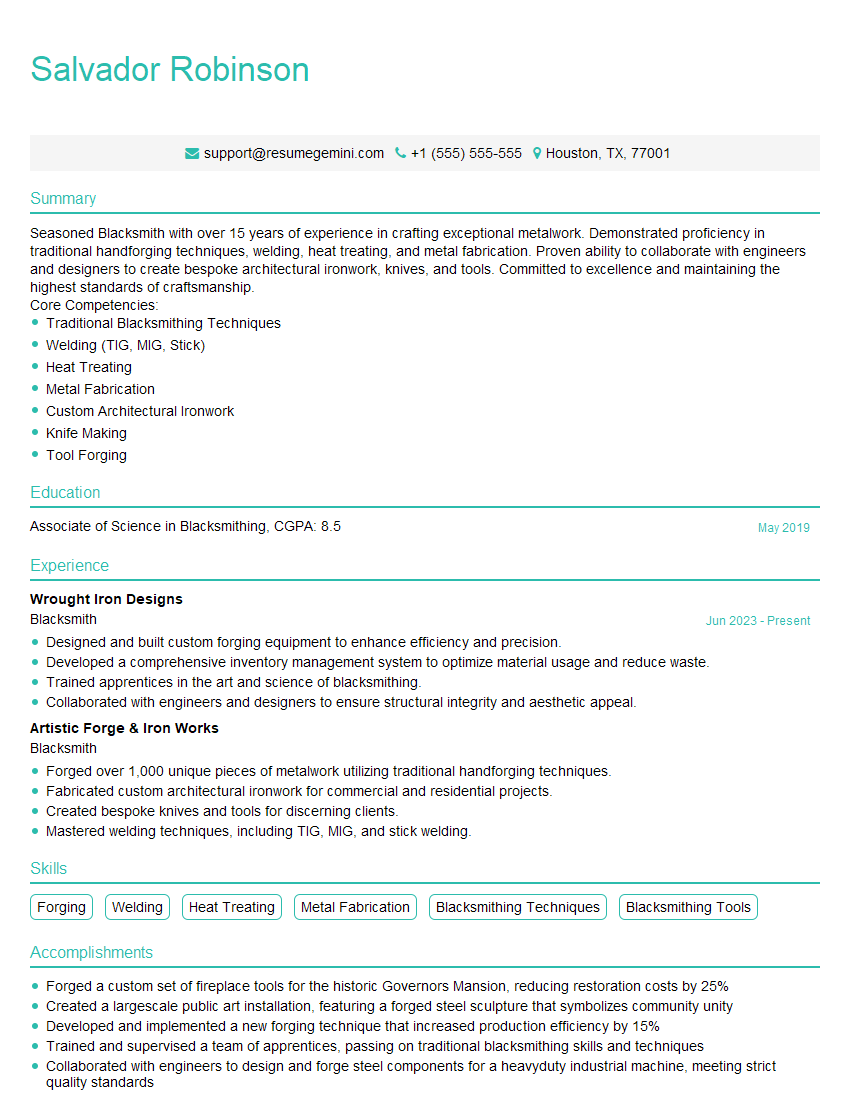

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blacksmith

1. Describe the steps involved in forging a horseshoe?

In forging a horseshoe, I follow a meticulous process:

- Start by heating the iron rod in the forge until it becomes incandescent.

- Use a hammer to shape the heated rod into a U-shape.

- Insert the U-shape into the swage (a tool with a curved groove) and hammer it to create the horseshoe shape.

- Punch holes at the ends of the horseshoe for nailing.

- Heat the horseshoe again to temper it, increasing its strength and durability.

2. How do you determine the correct temperature for forging different metals?

Visual Cues

- Black Heat: Metal appears black and non-luminous.

- Dull Red Heat: Metal appears dull red and glows slightly.

- Bright Red Heat: Metal glows brightly, indicating appropriate temperature for forging.

- Orange Heat: Metal becomes more orange in color, suitable for forging certain materials.

Using a Temperature Measuring Device

- Insert a thermocouple or pyrometer into the metal to measure its temperature accurately.

Experience and Knowledge

- As an experienced blacksmith, I rely on knowledge and practice to estimate temperatures based on metal color and behavior.

3. Explain the difference between hot forging and cold forging.

The primary difference lies in the temperature of the metal being worked:

- Hot Forging: Metal is heated to temperatures above its recrystallization point, allowing for easier shaping and manipulation.

- Cold Forging: Metal is worked at room temperature or slightly above, resulting in increased strength but requiring more force and specialized techniques.

4. What is the importance of annealing in the forging process?

Annealing involves heating metal to a specific temperature and slowly cooling it:

- Softening: Annealing reduces the hardness and increases the ductility of the metal, making it easier to shape.

- Stress Relief: It removes internal stresses created during forging, improving the metal’s strength and preventing cracking.

- Grain Refinement: Annealing promotes the formation of smaller and more uniform grains, enhancing the metal’s properties.

5. What techniques do you use for surface finishing different metal objects?

I employ various techniques to create diverse surface finishes:

- Hammering: Using various hammers and textures, I create unique patterns and textures on the metal surface.

- Sandblasting: I use a sandblaster to remove surface impurities and achieve a smooth or textured finish.

- Wire Brushing: With wire brushes, I remove oxidation and create a brushed or satin finish.

- Chemical Patination: I apply chemical solutions to create controlled oxidation and enhance visual appeal.

6. What are the common types of welding used in blacksmithing?

As a blacksmith, I utilize several welding techniques:

- Forge Welding: Heating metal pieces to welding temperature and hammering them together without additional materials.

- TIG Welding: Using a non-consumable tungsten electrode to create an arc and weld metal pieces.

- MIG Welding: Feeding a consumable wire electrode through a welding gun to create an arc and weld metal pieces.

- Arc Welding: Using a consumable stick electrode to create an arc and weld metal pieces.

7. How do you ensure the quality and strength of your forged products?

Quality assurance is paramount in my work:

- Material Selection: I carefully select high-quality metals that meet the desired properties for each project.

- Temperature Control: I precisely control forging temperatures using a pyrometer or visual cues to achieve optimal material properties.

- Hammering Techniques: I employ proper hammering techniques to avoid defects and ensure even grain distribution.

- Post-Forge Treatments: I perform heat treatments such as annealing or tempering to enhance strength and durability.

- Testing: I conduct thorough inspections, including visual examination and, when necessary, destructive testing, to verify the product’s integrity.

8. Describe your experience in creating custom ornamental pieces.

Throughout my career, I have developed a strong portfolio of custom ornamental pieces:

- Collaboration with Designers: I work closely with designers to translate their concepts into tangible forged creations.

- Intricate Detailing: I possess the skills to execute intricate and delicate designs, adding aesthetic value to architectural and decorative elements.

- Historical Replication: I have experience in meticulously replicating historical ornamental pieces, preserving cultural heritage through my craft.

9. What are your favorite projects that showcase your blacksmithing abilities?

Among my most notable projects are:

- Restoration of Historic Gates: I meticulously restored intricate wrought-iron gates for a historic building, preserving their beauty and functionality.

- Custom Railings and Balustrades: I designed and crafted elegant railings and balustrades for a grand staircase, combining aesthetics with structural integrity.

- Ornate Architectural Elements: I forged decorative elements such as finials, scrollwork, and rosettes for a prestigious cathedral, contributing to its architectural grandeur.

10. How do you stay up-to-date with advancements in blacksmithing techniques?

To stay current, I actively pursue continuing education and professional development:

- Workshops and Conferences: I attend workshops and conferences to learn new techniques and share knowledge with fellow blacksmiths.

- Online Resources: I explore online forums, tutorials, and videos to expand my knowledge and stay informed about industry best practices.

- Experimentation and Research: I continually experiment with different techniques and materials to push the boundaries of my craft and innovate new designs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blacksmith.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blacksmith‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blacksmiths are highly skilled metalworkers who use traditional techniques to create and repair a wide range of metal objects. They are responsible for:

1. Shaping and forging metals

Blacksmiths use anvil, forge, and hammer to shape metals into desired forms. They work with different types of metals, including iron, steel, and aluminum.

- Heating metal to high temperatures

- Hammering and shaping metal using various tools

2. Creating and repairing metal objects

Blacksmiths create a wide range of objects using metal, including tools, furniture, and decorative items. They also repair damaged metal objects.

- Building fences, gates, and other structures

- Repairing farm equipment and other machinery

3. Welding and cutting metals

Blacksmiths use welding and cutting equipment to join and separate metal pieces. They also use grinding and polishing equipment to finish metal objects.

- Joining metal pieces using welding techniques

- Cutting and shaping metal using cutting tools

4. Maintaining and repairing equipment

Blacksmiths are responsible for maintaining and repairing their equipment, including forge, anvil, and hammer. They also perform regular maintenance on their welding and cutting equipment.

- Inspecting equipment for damage and wear

- Repairing and replacing damaged equipment

Interview Tips

Preparing for a blacksmith interview can be daunting, but with the right approach, you can ace it. Here are some tips to help you succeed:

1. Research the company and the position

Take the time to learn about the company and the specific position you are applying for. This will help you understand the company’s culture and the expectations for the role.

- Visit the company website and read about their history, mission, and values.

- Research the specific position you are applying for and make note of the required skills and experience.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why do you want to work for this company?” Prepare your answers to these questions in advance so that you can deliver them confidently.

- Come prepared with examples of your skills and experience that are relevant to the position.

- Be able to articulate why you are interested in working for the company.

3. Dress professionally and arrive on time

First impressions matter, so dress professionally for your interview. Arrive on time, and be prepared to introduce yourself and shake hands with the interviewer.

- Wear clean, pressed clothes and comfortable shoes.

- Arrive for your interview 5-10 minutes early.

4. Be enthusiastic and positive

Interviewers want to hire people who are enthusiastic about the job and the company. Be positive and upbeat during your interview, and show the interviewer that you are excited about the opportunity.

- Smile and make eye contact with the interviewer.

- Be positive and enthusiastic about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blacksmith interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.