Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blacktop-Paver Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

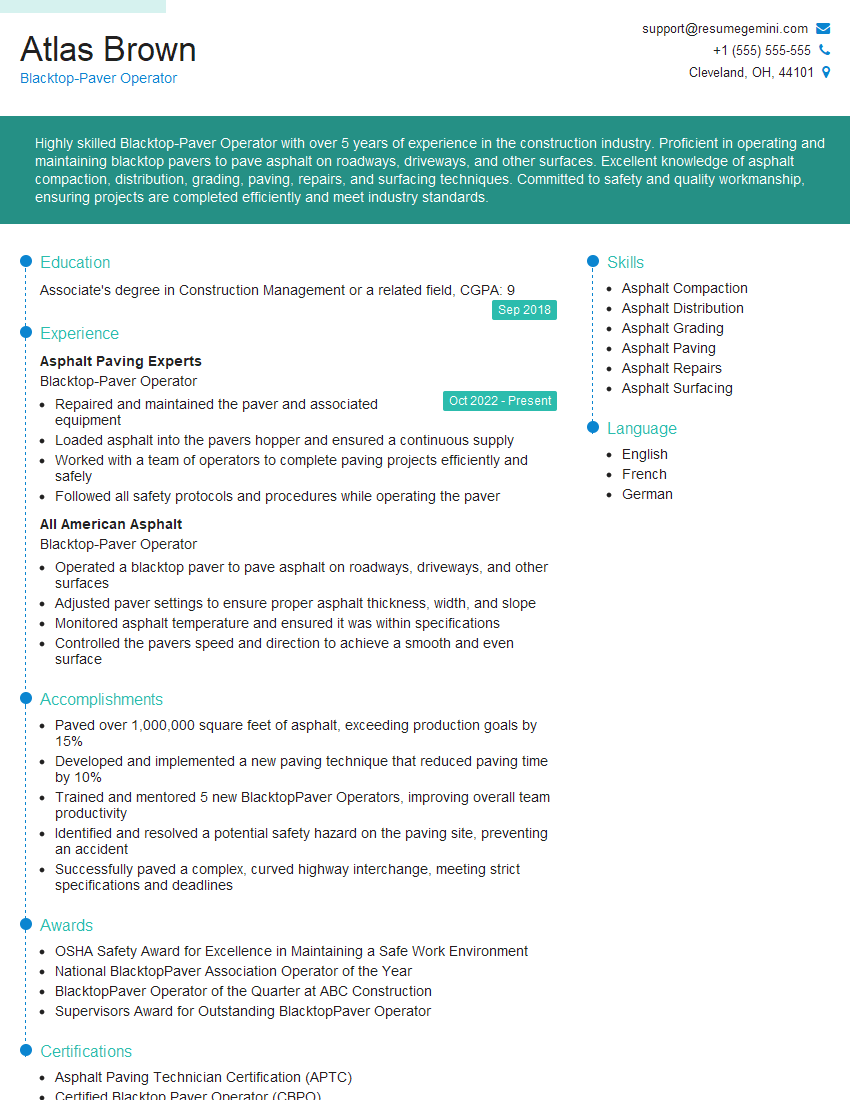

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blacktop-Paver Operator

1. How do you determine the correct thickness and compaction of the asphalt layer?

To determine the correct thickness and compaction of the asphalt layer, I follow these steps:

- Refer to the project specifications to determine the desired thickness.

- Use a nuclear density gauge or other compaction testing equipment to measure the density and compaction of the asphalt.

- Adjust the paver settings and compaction equipment as needed to achieve the desired thickness and compaction.

- Perform density and thickness testing throughout the paving process to ensure quality control and compliance with specifications.

2. Describe the types of asphalt mixtures and their suitability for different applications.

Hot Mix Asphalt (HMA)

- Most common type of asphalt

- Mixed at high temperatures

- Suitable for high-traffic areas, such as roads and highways

Warm Mix Asphalt (WMA)

- Mixed at lower temperatures than HMA

- Reduced emissions and energy consumption

- Suitable for moderately trafficked areas and patching

Cold Mix Asphalt (CMA)

- Mixed at ambient temperatures

- No heating required

- Suitable for low-traffic areas and temporary repairs

3. How do you troubleshoot common problems that arise during the paving process?

Common problems during paving include:

- Rutting and shoving: Caused by excessive weight or improper compaction. I adjust paver settings, increase compaction, and use a stiffer asphalt mix.

- Cracking: Caused by thermal stresses or poor subgrade preparation. I ensure proper joint spacing, use crack sealants, and improve subgrade drainage.

- Bleeding: Caused by excessive asphalt binder. I adjust the asphalt mix design, reduce the binder content, and improve drainage.

- Segregation: Caused by improper mixing or placement. I adjust paver settings, clean the paver hopper, and use a more cohesive asphalt mix.

4. What are the safety precautions that you must observe when operating a blacktop paver?

To ensure safety when operating a blacktop paver, I adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat.

- Inspect the paver and equipment before starting work.

- Be aware of surroundings and potential hazards.

- Operate the paver safely and according to manufacturer’s instructions.

- Follow proper lockout/tagout procedures when servicing the paver.

5. How do you maintain and calibrate the equipment used in the paving process?

To ensure optimal performance and accuracy, I maintain and calibrate the following equipment:

- Paver: I perform regular inspections, lubricate components, and calibrate sensors to ensure proper operation.

- Nuclear density gauge: I calibrate the gauge regularly and follow proper safety protocols when handling radioactive material.

- Compaction equipment: I inspect rollers and plates for wear and damage, and calibrate the compaction force according to specifications.

6. Explain the importance of proper joint placement and compaction when paving.

Proper joint placement and compaction are crucial for the longevity and performance of the asphalt pavement:

- Joint placement: Overlapping joints prevent water intrusion and reduce the risk of cracking. I ensure proper joint spacing and alignment.

- Compaction: Compacting joints properly creates a strong bond between the adjacent asphalt sections, preventing separation and rutting.

7. How do you communicate with other members of the paving crew to ensure efficient and safe operations?

Effective communication is vital for a smooth and safe paving operation:

- Hand signals: I use standardized hand signals to communicate with the paver operator, rollers, and other crew members.

- Verbal communication: I maintain clear and open communication with the crew, discussing any issues or changes.

- Radios: I use radios to stay connected with other crew members and coordinate activities, especially in large-scale projects.

8. What factors influence the selection of the appropriate asphalt mix for a specific paving project?

The selection of the asphalt mix depends on several factors:

- Traffic volume and type: Heavier traffic requires a more durable asphalt mix with a higher binder content.

- Climate: Extreme temperatures and moisture levels influence the asphalt mix design to prevent cracking or rutting.

- Subgrade conditions: The stability and drainage of the subgrade determine the thickness and type of asphalt mix required.

- Project specifications: The project engineer may specify specific mix designs or performance requirements.

9. Describe the techniques used to control the temperature of the asphalt during paving.

Controlling asphalt temperature is crucial to ensure proper placement and compaction:

- Temperature sensors: I use temperature sensors to monitor asphalt temperatures in the paver and haul trucks.

- Insulated trucks: Insulated trucks help maintain the asphalt temperature during transport.

- Thermal blankets: Thermal blankets can be used to cover the asphalt after paving to retain heat.

- Anti-stripping agents: These additives help prevent moisture damage and improve bonding between the asphalt and aggregate.

10. Explain the concept of “rideability” in asphalt paving and how you achieve it.

Rideability refers to the smoothness and comfort of the paved surface:

- Leveling and smoothness: I use a leveling system to ensure the asphalt is level and free of bumps.

- Compaction: Proper compaction creates a dense and stable surface that prevents ruts and depressions.

- Joint smoothness: I carefully place and compact joints to minimize any noticeable bumps or transitions.

- Texture: The asphalt texture is designed to provide adequate traction while minimizing noise and vibration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blacktop-Paver Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blacktop-Paver Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Blacktop-Paver Operator is responsible for operating and maintaining asphalt paving equipment, ensuring the smooth and efficient application of asphalt on various surfaces. Their duties include:

1. Equipment Operation

Operate blacktop pavers to lay asphalt on surfaces such as roads, driveways, and parking lots.

- Control the paver’s speed, direction, and thickness of the asphalt layer.

- Monitor sensors and adjust the paver’s settings to ensure proper leveling and compaction.

2. Equipment Maintenance

Inspect and maintain blacktop pavers to ensure they are in good working condition.

- Conduct daily inspections, lubricate moving parts, and replace worn components.

- Troubleshoot and resolve mechanical issues, ensuring minimal downtime.

3. Material Handling

Coordinate with material suppliers to ensure a steady supply of asphalt mix.

- Load and unload asphalt mix into pavers, ensuring it is evenly distributed.

- Monitor the temperature of the asphalt mix and adjust settings if necessary.

4. Job Site Management

Work with other construction personnel to ensure smooth progress on paving projects.

- Coordinate with surveyors and engineers to mark grade stakes and set up the paver.

- Follow safety protocols and ensure a clean and organized work environment.

Interview Tips

To ace the interview for a Blacktop-Paver Operator position, consider the following tips:

1. Research the Company and Position

Thoroughly research the company and the specific blacktop-paving project they are involved in.

- Understand their reputation, project history, and the size and scope of the project.

- This knowledge will demonstrate your interest and prepare you to answer questions related to your understanding of the role and their expectations.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating and maintaining blacktop pavers.

- Quantify your experience by providing specific examples of projects, equipment used, and accomplishments.

- Showcase your problem-solving abilities and how you have handled challenges on previous paving projects.

3. Demonstrate Safety Awareness and Commitment

Blacktop paving involves heavy machinery and hazardous materials.

- Emphasize your adherence to safety protocols and your commitment to maintaining a safe work environment.

- Provide examples of your safety practices and how you promote safety on the job site.

4. Be Prepared to Discuss Equipment Knowledge

Interviewers will likely assess your knowledge of blacktop pavers and associated equipment.

- Be familiar with different paver types, their components, and how to troubleshoot common issues.

- Demonstrate your understanding of asphalt mix properties and how they impact the paving process.

Next Step:

Now that you’re armed with the knowledge of Blacktop-Paver Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Blacktop-Paver Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini