Are you gearing up for a career in Blade Changer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Blade Changer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

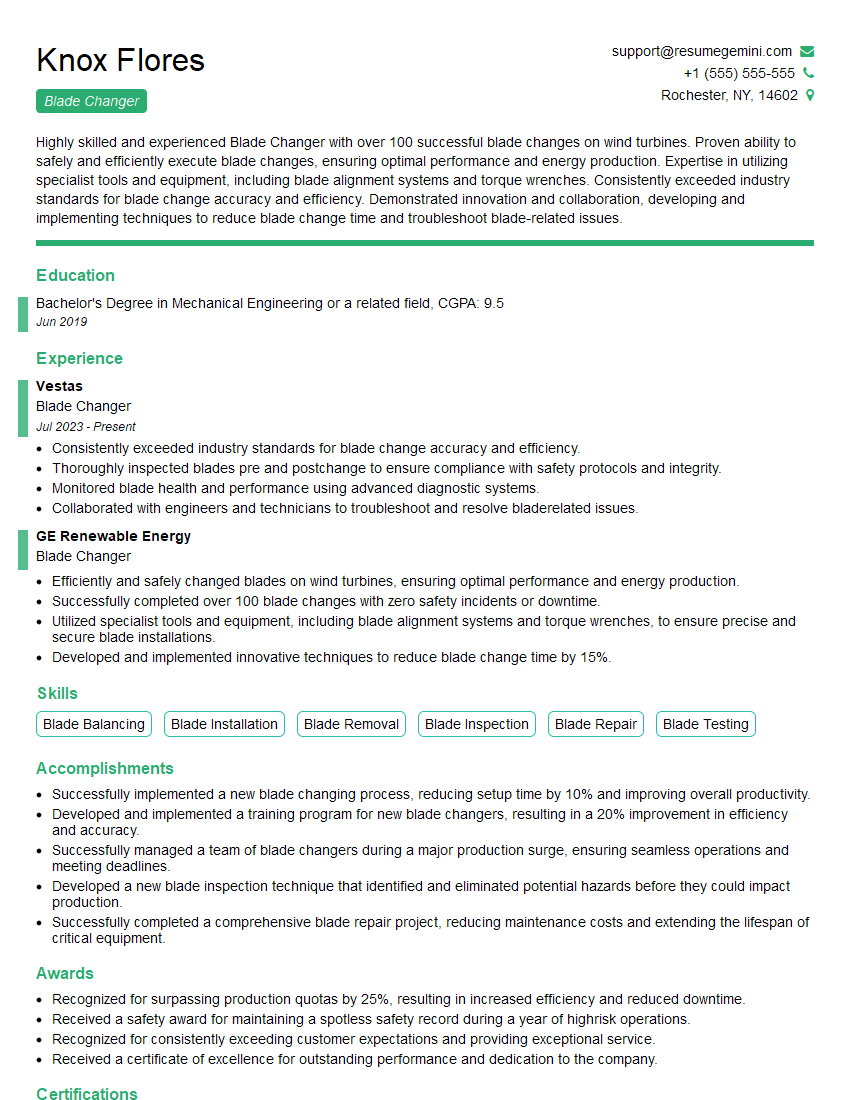

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blade Changer

1. What is the primary function and purpose of a blade changer?

The primary function of a blade changer is to automatically exchange worn-out or damaged razor blades on a production line. Its purpose is to maintain optimal cutting performance, reduce downtime, and improve safety.

2. Describe the different types of blade changers and their respective advantages and disadvantages.

Mechanical Blade Changers

- Pros: Robust and reliable, handle high-impact environments.

- Cons: Slower speed and limited blade adjustment capabilities.

Pneumatic Blade Changers

- Pros: Fast and efficient, provide precise blade adjustments.

- Cons: Requires compressed air supply, may be more complex to maintain.

Hydraulic Blade Changers

- Pros: Powerful and reliable, suitable for heavy-duty applications.

- Cons: Slower speed than pneumatic systems, requires hydraulics infrastructure.

3. How does a blade changer integrate with a production line?

Blade changers typically integrate with the production line via control systems, such as PLCs or industrial computers. These systems send signals to the blade changer to initiate blade exchanges based on factors like cutting performance or blade lifespan.

4. What are the key considerations when selecting a blade changer for a specific application?

- Production speed and volume

- Type of material being cut

- Blade type and size

- Environmental conditions

- Safety requirements

5. Explain the maintenance and calibration procedures for blade changers.

- Regular cleaning and inspection

- Blade replacement and adjustment

- Sensor calibration

- System testing and performance verification

6. How do you troubleshoot common problems associated with blade changers?

- Identify the problem source through error codes or visual inspection.

- Check for loose connections, air leaks, or hydraulic fluid issues.

- Calibrate sensors or adjust blade settings.

- Consult manufacturer documentation or technical support.

7. What are the safety features and protocols involved in operating blade changers?

- Guarding and interlocks to prevent contact with moving parts.

- Emergency stop buttons and sensors.

- Proper training and safety procedures for operators.

- Adherence to industry standards and regulations.

8. How do you stay abreast of the latest advancements in blade changer technology?

- Attend industry conferences and trade shows.

- Read technical journals and publications.

- Engage with manufacturers and suppliers.

- Participate in online forums and discussion groups.

9. Describe a particularly challenging blade changer project you have worked on and how you overcame the obstacles.

I worked on a project to integrate a high-speed blade changer into a production line for a medical device manufacturer. The challenge was maintaining precise blade positioning for intricate cuts. I implemented a laser guidance system and developed a calibration procedure that ensured consistent accuracy, reducing waste and downtime.

10. How would you contribute to our team as a Blade Changer?

- My expertise in blade changer selection, integration, and maintenance.

- Ability to troubleshoot and resolve issues efficiently.

- Commitment to safety and adherence to industry standards.

- Strong communication and collaboration skills.

- Dedication to continuous improvement and innovation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blade Changer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blade Changer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blade Changers are responsible for the safe and efficient operation of wind turbines. They work at heights to maintain and repair wind turbine blades, ensuring that the turbines are operating at peak performance levels.

1. Inspecting and Maintaining Wind Turbine Blades

Blade Changers are responsible for inspecting and maintaining wind turbine blades. They must be able to identify any damage or defects that could compromise the safety or efficiency of the turbine. They must also be able to make necessary repairs and replacements to ensure that the turbine is operating at peak performance levels.

2. Working at Heights

Blade Changers work at heights on a daily basis. They must be able to climb ladders and towers and work on the turbines themselves. They must also be able to work in confined spaces and in inclement weather conditions.

3. Operating Heavy Machinery

Blade Changers use a variety of heavy machinery to perform their job. They must be able to operate cherry pickers, cranes, and other equipment safely and efficiently.

4. Following Safety Procedures

Safety is paramount in the wind energy industry. Blade Changers must be able to follow all safety procedures and regulations. They must also be able to work independently and take initiative to ensure the safety of themselves and their colleagues.

Interview Tips

Preparing for a job interview can be a daunting task, but it doesn’t have to be. By following these tips and practicing your answers, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can also use this information to tailor your answers to the interviewer’s questions.

2. Practice Your Answers

One of the best ways to prepare for an interview is to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview itself. You can also use this time to develop your own questions to ask the interviewer.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you are applying for. You should also arrive on time and be prepared to answer questions about your experience and qualifications.

4. Be Enthusiastic and Confident

Interviewers are looking for candidates who are enthusiastic and confident about their abilities. Be sure to make eye contact, speak clearly, and answer questions in a positive and professional manner. You should also be respectful of the interviewer’s time and be willing to answer any questions they may have.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Blade Changer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.