Feeling lost in a sea of interview questions? Landed that dream interview for Blanket Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Blanket Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

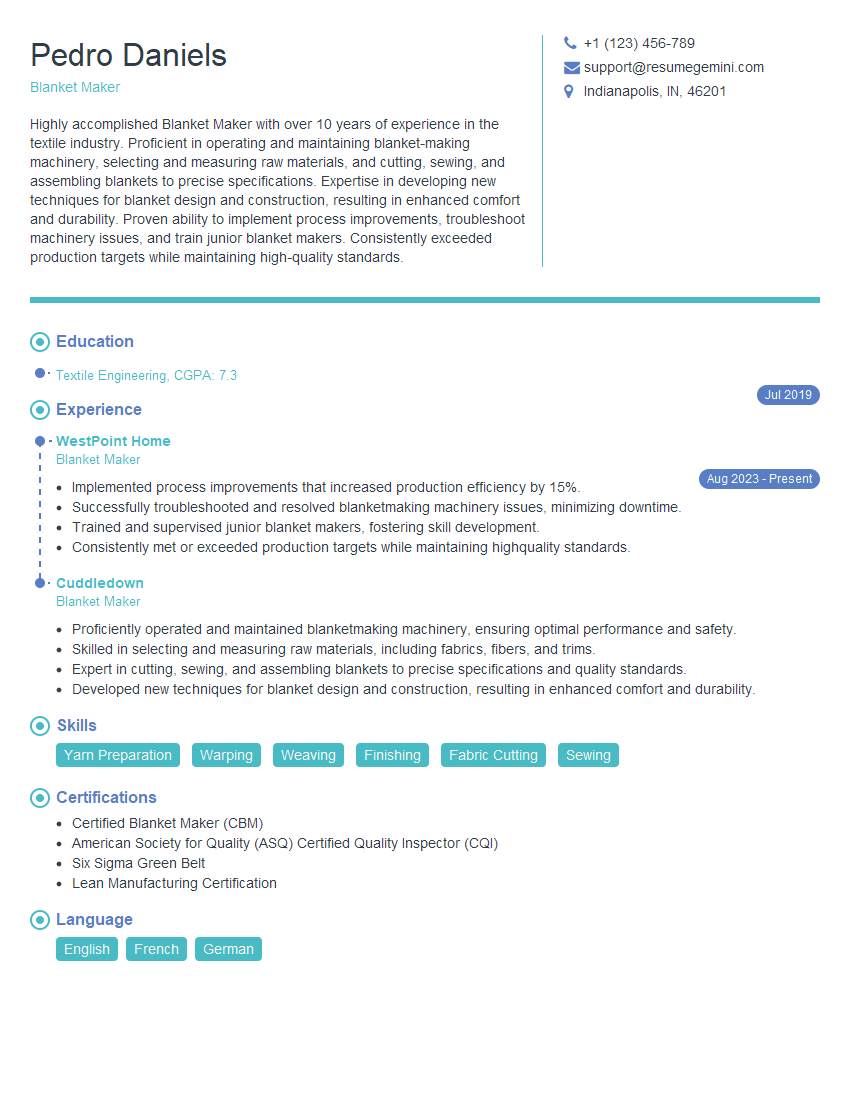

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blanket Maker

1. What are the key considerations when selecting the right materials for blanket making?

When selecting materials for blanket making, several key considerations play a crucial role:

- Fiber Type: Different fibers (e.g., cotton, wool, synthetic) offer unique properties such as warmth, breathability, and durability.

- Thread Count: A higher thread count generally indicates a softer, more durable blanket.

- Weave Pattern: The weave (e.g., plain, twill, satin) determines the blanket’s texture, drape, and warmth.

- Weight: Blankets vary in weight from lightweight for summer use to heavier for winter warmth.

- Allergy Considerations: Some materials, such as wool, may trigger allergies in certain individuals.

2. Describe the different techniques used in blanket manufacturing and their advantages and disadvantages.

Knitting

- Advantages: Flexible, stretchy, quick production.

- Disadvantages: May run or snag, less durable than woven fabrics.

Weaving

- Advantages: Durable, less likely to run, versatile patterns.

- Disadvantages: Slower production, more expensive.

Fleece

- Advantages: Soft, warm, lightweight.

- Disadvantages: Can shed, less breathable.

3. How do you ensure the quality and consistency of your blankets?

Ensuring quality and consistency involves several measures:

- Material Inspection: Raw materials are thoroughly inspected before production.

- Process Control: Production parameters (e.g., thread tension, weaving speed) are strictly monitored.

- Quality Assurance Testing: Blankets undergo rigorous testing to meet specifications for warmth, durability, and appearance.

- Regular Audits: Independent audits verify adherence to quality standards.

- Customer Feedback Analysis: Customer feedback is collected and analyzed to identify areas for improvement.

4. What are the latest trends and innovations in blanket manufacturing?

Current trends and innovations include:

- Smart Blankets: Blankets that can track sleep patterns and adjust temperature for optimal comfort.

- Sustainable Materials: Use of eco-friendly and organic materials such as bamboo and recycled fibers.

- Personalized Blankets: Customization with unique designs, embroidery, and special features.

- Advanced Weaving Techniques: New weaving techniques create blankets with innovative textures, patterns, and durability.

- Hybrid Blankets: Combinations of different materials, such as wool and fleece, for enhanced warmth and breathability.

5. How do you stay up-to-date with the latest industry best practices?

I stay up-to-date with industry best practices through the following methods:

- Industry Events: Attendance at trade shows, conferences, and workshops.

- Professional Organizations: Membership in organizations like the International Association of Home Textiles Manufacturers.

- Technical Publications: Reading industry journals and research papers.

- Collaboration: Networking with other blanket manufacturers and experts.

- Online Resources: Utilizing industry websites, forums, and online learning platforms.

6. Describe the quality control procedures you follow during blanket production.

Quality control procedures include:

- Raw Material Inspection: Verifying the quality and specifications of materials.

- In-Process Inspection: Monitoring production processes to ensure adherence to standards.

- Final Inspection: Comprehensive examination of finished blankets for defects and conformity to specifications.

- Sampling and Testing: Random sampling and laboratory testing to assess performance and durability.

- Statistical Process Control: Using statistical techniques to identify and eliminate variations in production.

7. How do you manage production schedules to meet customer demands?

Effective production schedule management involves:

- Demand Forecasting: Using historical data and market analysis to predict customer demand.

- Capacity Planning: Assessing production capacity and optimizing schedules to meet demand.

- Just-in-Time Production: Producing blankets as close to customer order time as possible to minimize inventory.

- Prioritization: Setting priorities for orders based on urgency and customer requirements.

- Collaboration: Coordinating with suppliers, logistics providers, and other stakeholders to ensure timely delivery.

8. What is your experience with different types of blanket production equipment?

I have extensive experience with various blanket production equipment, including:

- Weaving Machines: Operating and maintaining looms for blanket weaving.

- Knitting Machines: Setting up and operating knitting machines for blanket production.

- Fleece Production Lines: Handling equipment for fleece blanket making, from fiber preparation to finished product.

- Finishing Equipment: Using machines for blanket washing, drying, and finishing processes.

- Quality Control Equipment: Utilizing specialized equipment for blanket testing and inspection.

9. How do you handle customer complaints and ensure customer satisfaction?

I approach customer complaints with the following steps:

- Active Listening: Attentively listening to customer concerns and acknowledging their dissatisfaction.

- Investigation: Conducting thorough investigations to identify the root cause of the complaint.

- Resolution: Proposing appropriate solutions and working with customers to resolve the issue.

- Follow-Up: Contacting customers after the complaint has been resolved to ensure satisfaction.

- Continuous Improvement: Using customer feedback to identify areas for improvement in products and services.

10. How do you ensure sustainability and environmental responsibility in your blanket manufacturing practices?

Sustainability and environmental responsibility are key considerations in my blanket manufacturing practices:

- Material Selection: Using eco-friendly and sustainable materials, such as organic cotton and recycled fibers.

- Energy Efficiency: Optimizing production processes to reduce energy consumption.

- Waste Reduction: Implementing waste reduction programs and recycling initiatives.

- Water Conservation: Using water-efficient technologies and reducing water usage in production.

- Certifications: Obtaining certifications like GOTS (Global Organic Textile Standard) to demonstrate sustainability efforts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blanket Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blanket Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Blanket Maker, you will primarily be responsible for manufacturing and finishing blankets, adhering to established quality standards and production timelines.

1. Raw Material Preparation

Your tasks will involve preparing and measuring fabric materials, ensuring their suitability for blanket production. This includes examining fabric quality, cutting it to precise dimensions, and preparing it for sewing or other manufacturing processes.

2. Blanket Assembly

You will be required to assemble blankets according to specified design patterns and dimensions. This includes sewing or bonding fabric layers together, inserting fillings, and finishing the edges. You must ensure the blankets meet the required specifications for size, weight, and aesthetic appearance.

3. Quality Control

Maintaining quality is crucial, so you will be responsible for inspecting blankets at various stages of production to ensure they meet established standards. This involves checking for defects, proper stitching, correct dimensions, and adherence to production specifications.

4. Equipment Maintenance

To ensure smooth production, you will be required to maintain and calibrate the equipment used in blanket making. This includes cleaning, lubricating, and troubleshooting machines such as sewing machines, cutting machines, and finishing equipment.

5. Workshop Management

You may be involved in managing the blanket-making workshop, including maintaining a clean and organized work environment, monitoring inventory levels, and ensuring efficient production processes. You may also be responsible for training and supervising junior team members.

Interview Tips

Preparing for a Blanket Maker interview requires a combination of technical knowledge and an understanding of the industry. Here are some tips to help you ace your interview:

1. Research the Company

Before the interview, take the time to research the company you’re applying to. Learn about their history, products, and values. This demonstrates your interest in the company and your preparation for the interview.

2. Highlight Your Skills

In your resume and during the interview, emphasize your skills and experience that are relevant to the job. Focus on your ability to work with fabrics, operate manufacturing equipment, and maintain quality standards.

3. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” Practice your answers to ensure you can deliver them clearly and confidently.

4. Ask Relevant Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions about the company’s production processes, quality control measures, or growth opportunities.

5. Dress Professionally

First impressions matter, so dress professionally for the interview. This could mean wearing a suit or business casual attire. Make sure your clothes are clean, pressed, and fit well.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Blanket Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.