Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Blanking Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Blanking Machine Operator so you can tailor your answers to impress potential employers.

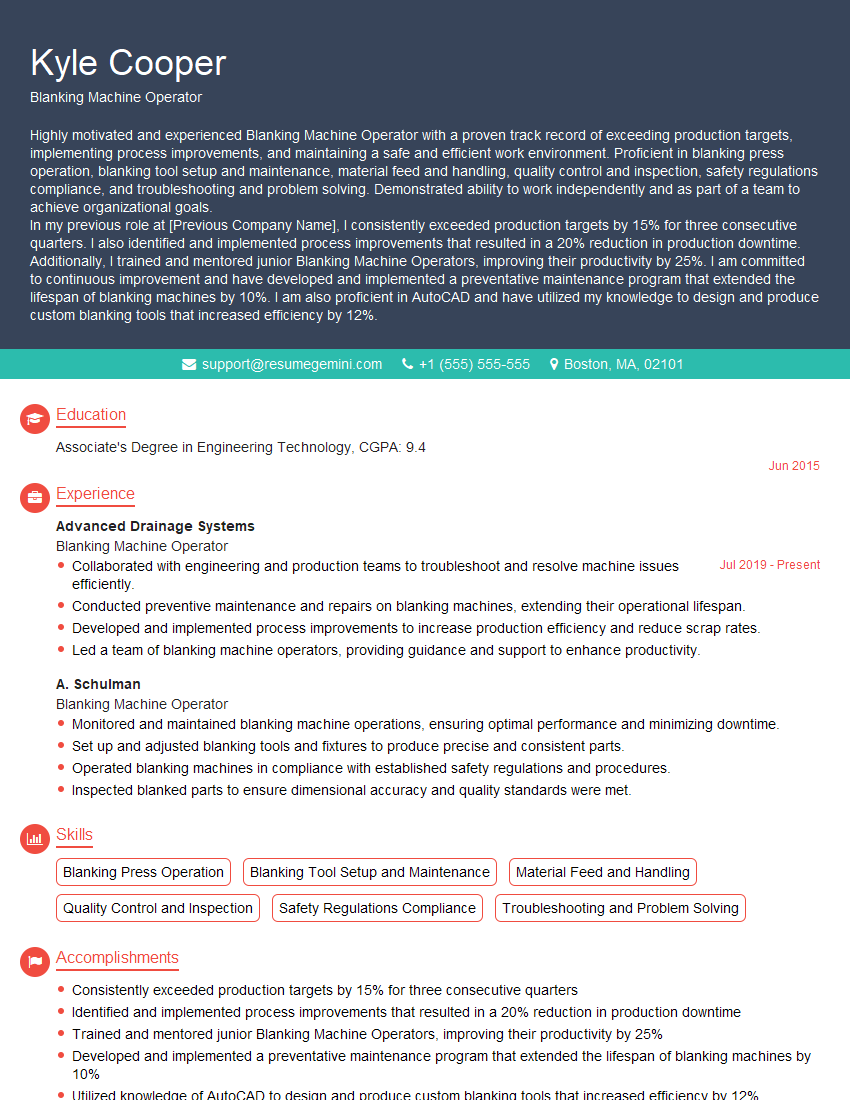

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blanking Machine Operator

1. Can you describe the basic operation of a blanking machine?

- Blanking machines use a punch and die to cut a shape out of sheet metal.

- The punch is attached to the ram, which moves up and down, while the die is mounted on the bed of the machine.

- When the ram is lowered, the punch enters the die and cuts out the shape.

2. What are the different types of blanking machines?

Mechanical Blanking Machines

- Mechanically driven

- Use a flywheel to store energy

- Can be used for a variety of materials

Hydraulic Blanking Machines

- Hydraulically driven

- Provide more precise control over the cutting process

- Can be used for a variety of materials

3. What are the common materials used in blanking?

- Steel

- Aluminum

- Copper

- Brass

4. What are the factors that affect the quality of a blanked part?

- Material thickness

- Punch and die clearance

- Machine speed

- Tool condition

- Lubrication

5. What are the safety precautions that should be taken when operating a blanking machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection.

- Keep hands and other body parts away from the punch and die area.

- Do not operate the machine if it is not properly guarded.

- Follow all manufacturer’s instructions for safe operation.

6. How do you troubleshoot a blanking machine that is not working properly?

- Check the power supply.

- Check the hydraulic system.

- Check the punch and die.

- Check the material thickness.

- Check the lubrication.

7. What is the difference between blanking and punching?

- Blanking removes a slug of material from the sheet, while punching creates a hole.

- Blanking is typically used when the part being cut out is needed, while punching is used when the hole is needed.

8. What are the advantages of using a blanking machine?

- Can produce high-quality parts with close tolerances.

- Can be used for a variety of materials.

- Can be automated for high-volume production.

9. What are the challenges of operating a blanking machine?

- Requires careful setup and maintenance.

- Can be dangerous if not operated properly.

- Can be expensive to purchase and operate.

10. What are your career goals as a blanking machine operator?

- To learn more about the operation and maintenance of blanking machines.

- To become a skilled and experienced blanking machine operator.

- To advance to a supervisory or management position.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blanking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blanking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blanking Machine Operators are responsible for operating blanking machines, which cut blank shapes out of metal sheets. They must ensure that the machines are set up correctly and that the blanks are produced to the correct specifications. They must also be able to troubleshoot any problems that may occur during operation.

Key job responsibilities include:

1. Setting up and operating blanking machines

Blanking Machine Operators must be able to set up and operate blanking machines safely and efficiently. They must be able to adjust the machine settings to produce blanks of the correct size and shape. They must also be able to troubleshoot any problems that may occur during operation.

2. Inspecting blanks

Blanking Machine Operators must be able to inspect blanks to ensure that they meet the correct specifications. They must be able to identify any defects or imperfections in the blanks. They must also be able to take corrective action to fix any defects or imperfections.

3. Maintaining blanking machines

Blanking Machine Operators must be able to maintain blanking machines in good working condition. They must be able to perform routine maintenance tasks, such as cleaning and lubricating the machine. They must also be able to identify and repair any problems that may occur with the machine.

4. Following safety procedures

Blanking Machine Operators must be able to follow safety procedures when operating blanking machines. They must be aware of the potential hazards associated with operating blanking machines and must take steps to protect themselves and others from injury.

Interview Tips

Preparing for an interview can be daunting, but by following a few simple tips, you can increase your chances of success. Here are some tips to help you ace your interview for a Blanking Machine Operator position:

1. Research the company and the position

Before you go to your interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can research the company’s website, read industry publications, and talk to people who work for the company.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It is important to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Blanking Machine Operator. Be prepared to talk about your experience in detail, including the specific tasks you have performed and the results you have achieved. You should also highlight any skills that are relevant to the position, such as your ability to operate blanking machines safely and efficiently, or your ability to troubleshoot problems.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic and positive about the position. Be sure to show your interest in the position and the company, and be positive about your ability to do the job.

5. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you are respectful of their time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Blanking Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Blanking Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.