Are you gearing up for an interview for a Blast Furnace Blower position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Blast Furnace Blower and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

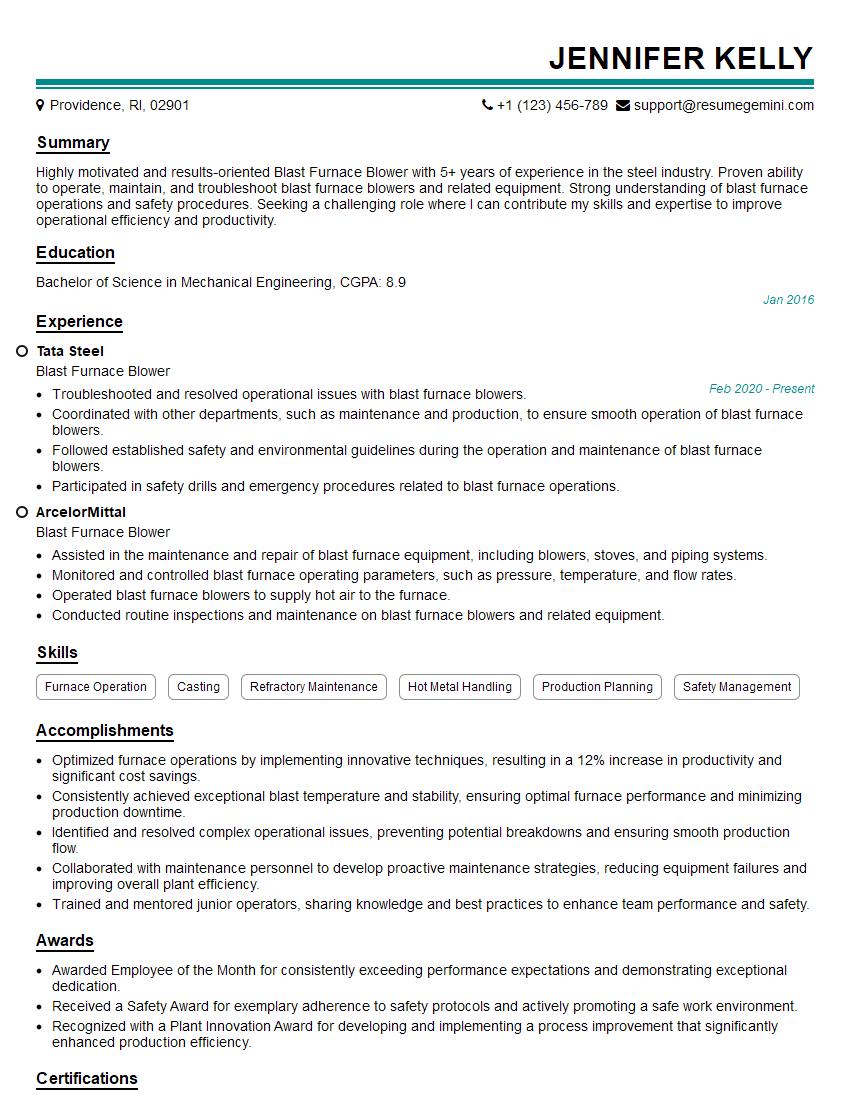

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blast Furnace Blower

1. What are the key responsibilities of a Blast Furnace Blower?

As a Blast Furnace Blower, my responsibilities include:

- Operating and monitoring blast furnace blowers to supply air to the furnace

- Adjusting blower speed and pressure to maintain optimal operating conditions

- Performing routine maintenance and troubleshooting on blowers and related equipment

- Monitoring blower performance and identifying any potential issues

- Ensuring compliance with safety regulations and procedures

2. Can you explain the process of blast furnace operation?

Preheating and Charging

- Iron ore, coke, and limestone are preheated in the sinter plant and charged into the blast furnace

Smelting

- Hot air from the stoves is blown into the furnace, reacting with the coke to create carbon monoxide

- Carbon monoxide reduces iron oxide to form molten iron

- Molten iron and slag (impurities) separate and collect at the bottom of the furnace

Tapping

- Molten iron is periodically tapped from the furnace into torpedo cars

- Slag is also periodically tapped off

3. What are the different types of blast furnace blowers?

The two main types of blast furnace blowers are:

- Turbo blowers: Driven by steam or gas turbines, they provide high-pressure air

- Centrifugal blowers: Electrically driven, they provide lower-pressure air

4. What are the safety precautions to be taken when working with blast furnace blowers?

- Wear appropriate personal protective equipment (PPE) such as safety glasses, earplugs, and gloves

- Be aware of the location of emergency shut-off switches

- Avoid working alone near blowers

- Follow all safety procedures and protocols

5. What are the common problems that can occur with blast furnace blowers?

Common problems include:

- Excessive vibration

- Bearing failure

- Seal leaks

- Motor problems

- Clogged air filters

6. How do you troubleshoot a blast furnace blower that is not delivering sufficient air pressure?

- Check the air filter for blockages

- Inspect the blower for any leaks

- Verify that the blower is operating at the correct speed

- Examine the motor and electrical connections

- Consult with a qualified technician if necessary

7. What is the importance of maintaining proper blower speed and pressure in a blast furnace?

- Ensures optimal combustion of coke and efficient reduction of iron ore

- Prevents furnace upsets and maintains stable operation

- Optimizes fuel consumption and reduces operating costs

8. How do you monitor and control the performance of a blast furnace blower?

- Monitor pressure and flow rate using gauges and sensors

- Measure vibration levels to detect potential problems

- Perform regular inspections and maintenance

- Analyze data and identify trends to optimize performance

9. What is the role of the blast furnace blower in reducing emissions?

- Ensuring efficient combustion reduces carbon monoxide and particulate matter emissions

- Maintaining proper pressure and flow prevents gas leakage and fugitive emissions

- Optimizing blower performance contributes to overall energy efficiency, reducing greenhouse gas emissions

10. How do you stay updated with the latest advancements in blast furnace blower technology?

- Attend industry conferences and exhibitions

- Read technical journals and publications

- Participate in online forums and discussion groups

- Collaborate with equipment manufacturers and engineers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blast Furnace Blower.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blast Furnace Blower‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blast Furnace Blowers are responsible for maintaining and operating the blast furnaces used in iron and steel production. Their key job responsibilities include:

1. Furnace Operation

Ensuring the smooth and efficient operation of the blast furnaces, by monitoring and controlling the furnace’s temperature, pressure, and gas flow.

- Adjusting blowers, dampers, and valves to maintain optimal operating conditions.

- Monitoring furnace performance and making necessary adjustments to ensure efficient production.

2. Equipment Maintenance

Maintaining and repairing the blast furnace equipment, including blowers, piping, and instrumentation.

- Performing preventive maintenance and repairs to minimize equipment downtime.

- Inspecting and replacing worn or damaged parts to ensure the safety and efficiency of the furnace.

3. Process Monitoring

Monitoring and analyzing the blast furnace process to identify and resolve any issues.

- Collecting and interpreting data from sensors and instruments to assess furnace performance.

- Investigating and resolving process problems to optimize production and minimize waste.

4. Safety and Environmental Compliance

Ensuring compliance with safety and environmental regulations related to blast furnace operations.

- Implementing and maintaining safety protocols to protect workers and the environment.

- Monitoring emissions and taking appropriate measures to minimize environmental impact.

Interview Tips

To prepare for a Blast Furnace Blower interview, it is important to:

1. Research the Company and Industry

Research the company and the iron and steel industry to gain an understanding of their operations, products, and market position. This will help you align your skills and experience with the company’s needs.

- Visit the company’s website and social media pages to learn about their culture, values, and recent developments.

- Read industry publications and news articles to stay informed about the latest trends and technologies in blast furnace operations.

2. Highlight Relevant Skills and Experience

In your resume and interview answers, emphasize your skills and experience that are directly relevant to blast furnace operations. These may include:

- Furnace operation and maintenance

- Process monitoring and troubleshooting

- Safety and environmental compliance

3. Prepare for Technical Questions

Be prepared to answer technical questions related to blast furnace operations, such as:

- How do you ensure optimal furnace temperature and pressure?

- What steps do you take to minimize equipment downtime?

- How do you investigate and resolve process problems?

4. Demonstrate Safety Awareness

Blast furnace operations can be hazardous, so it is important to demonstrate a strong commitment to safety. In your interview, discuss your safety practices and how you ensure compliance with safety regulations.

- Explain how you implement and maintain safety protocols.

- Describe your experience with emergency procedures and risk assessments.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blast Furnace Blower interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!